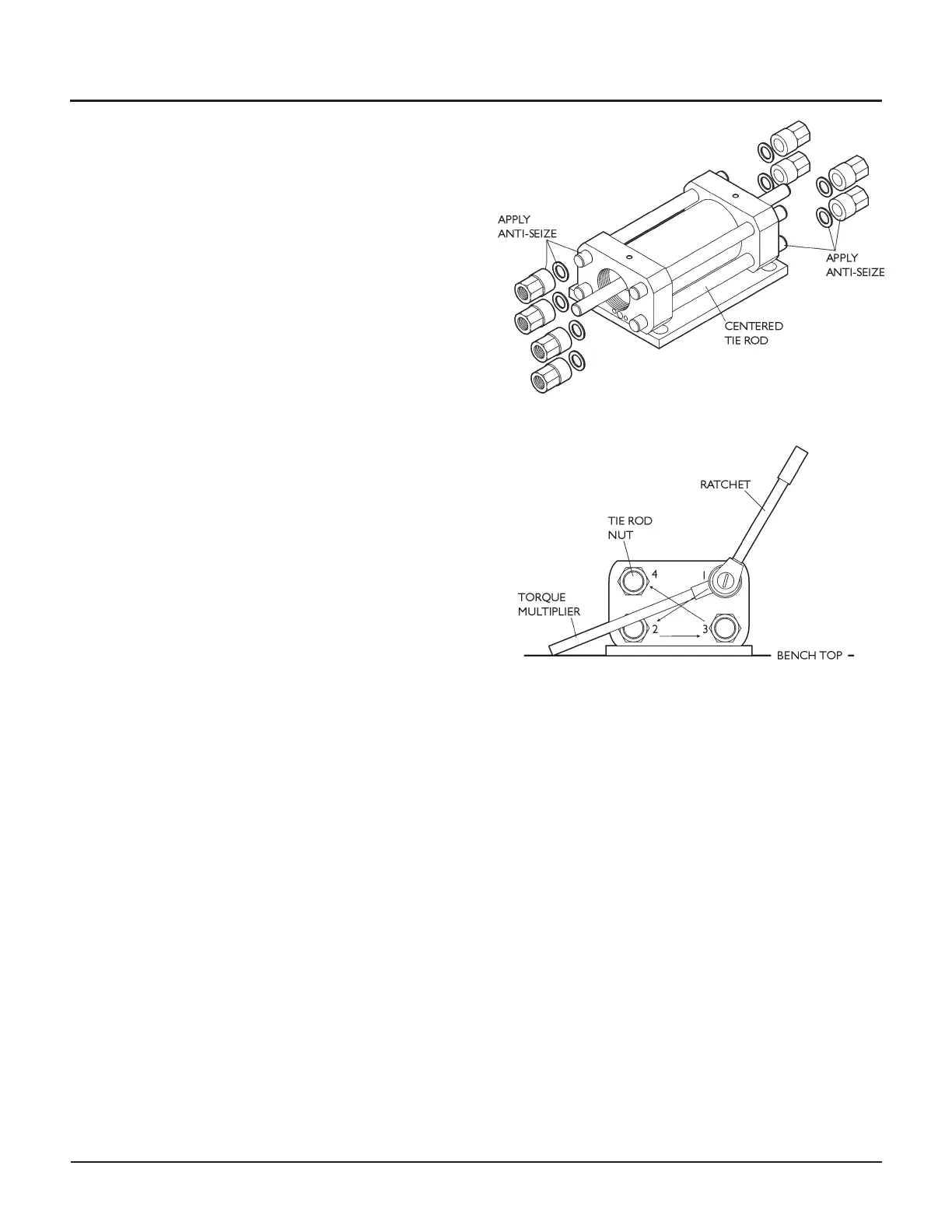

Center and hold the tie rods in place while installing

the washers and nuts onto the tie rods. Secure the

nuts hand tight.

42. Insert the second fixture plate screw (the long-block

intensifier has a pair) into the second end bell.

Tighten both sets of fixture plate screws to 30 ft-lb

(41 N-m). The screws must hold the end bells tight

against the fixture to prevent any misalignment.

Retighten the tie rod nuts to 20 ft-lb (27 N-m) to

keep the end bells seated.

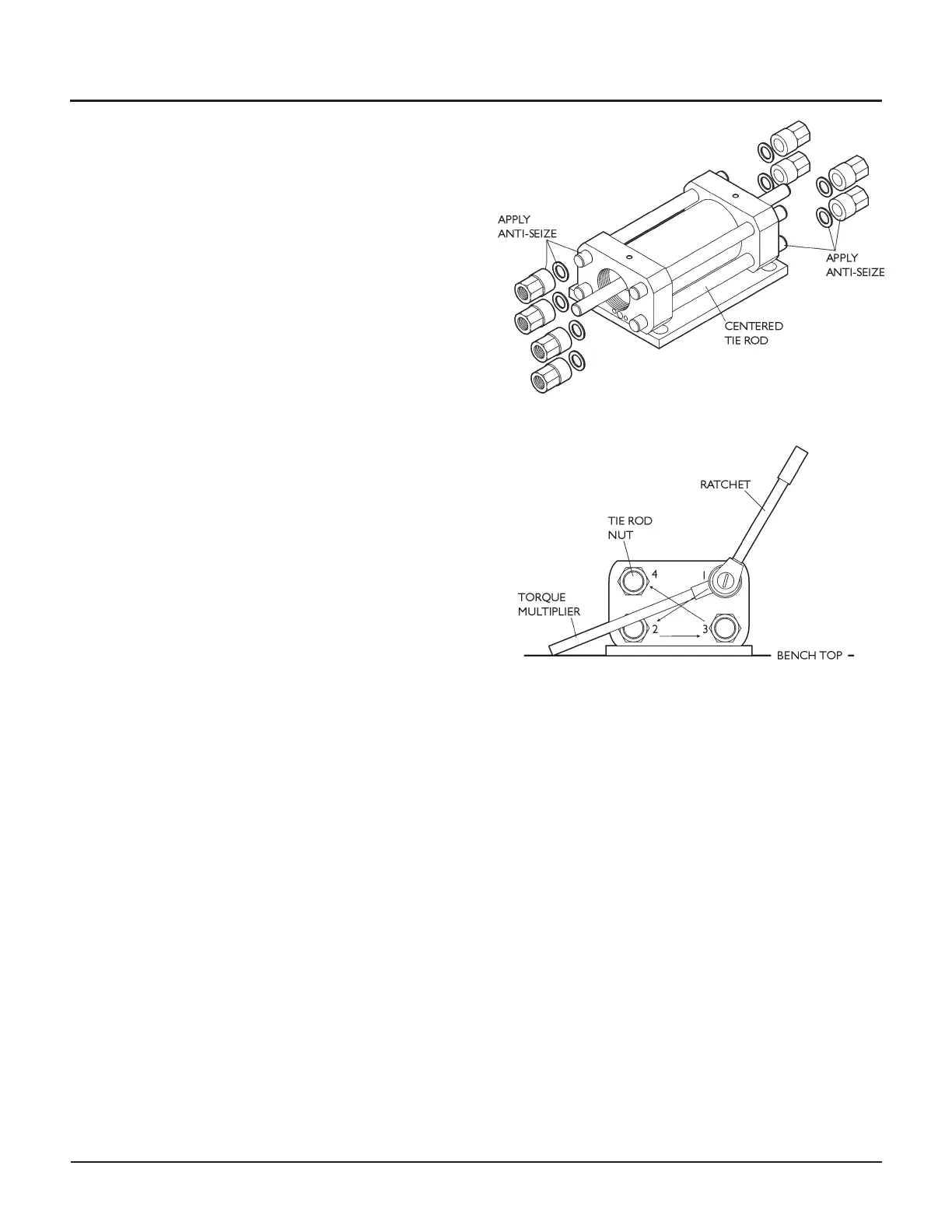

43. Tighten the tie rod nuts at one end of the tie rods

only, while restraining the nuts on the other end us

-

ing a suitable wrench, moving from one nut to the

next in a figure-8 pattern (shown on this page).

Note: You must follow this torque pattern (1-2-3-4).

Correctly moving from nut 2 to nut 3 crosses the

LONG dimension of the rectangular end bell. DO

NOT substitute with the pattern 1-2-4-3.

Using the torque wrench (and the torque multiplier

when necessary), tighten the nuts not more than

¼ turn at a time, following the figure-8 sequence.

Notes for using a torque multiplier

•

When using a torque multiplier, the torque wrench

setting must be calculated as follows:

TORQUE WRENCH SETTING =

REQUIRED NUT TORQUE

¸

ACTUAL MULTIPLIER RATIO

The actual multiplier ratio must be obtained from the

multiplier tool instructions. Beware that a tool may

be named with an implied multiplication ratio that is

not the actual ratio (for instance, a tool named X4

that has an actual multiplication ratio of 3.86 to 1).

Example: To obtain the 400 ft-lb nut torque using a

multiplier with a multiplication ratio of 3.92 to 1 will

require a torque wrench setting of:

TORQUE WRENCH SETTING =

400 FT-LB

¸

3.92 = 102 FT-LB

Torque all four nuts at one end to 200 ft-lb

(271 N-m), then 400 ft-lb (542 N-m), then 535 ft-lb

(725 N-m).

58 | M-376 © Flow International Corporation

94K HYPERPRESSURE INTENSIFIER

Loading...

Loading...