User instructions - Digital Positioner 3200MD LGENIM0059-01 10/08

21

7.11 ValveSight Configuration and

Diagnostic Software and HART 375

Handheld Communicator

Flowserve Corporation has written custom configuration and

diagnostic software for the Logix 3200MD digital positioner called

ValveSight. This software is available from a Flowserve representa-

tive.

The Logix 3200MD digital positioner supports and is supported by

the HART 375 Handheld Communicator. The Device Description

(DD) files and the manual listed below can be obtained from the

HART Communication Foundation or from your Flowserve represen-

tative. For more information please see the following guide:

• ProductManualfortheHARTCommunicator.

Diagnostic features such as the datalog, signature tests, and ramp

tests are performed using the ValveSight software. Certain calibra-

tion features such as loop calibration, analog output calibration, and

actuator pressure sensor calibrations are performed using the HART

375 Handheld Communicator or using diagnostic software such as

ValveSight.

8 Maintenance and Repair

8.1 Driver Module Assembly

The driver module assembly moves the spool valve by means

of a differential pressure across its diaphragm. Air is routed to

the driver module from the regulator through a flexible hose. A

barbed fitting connects the flexible hose to the driver module

assembly. Wires from the driver module assembly connect the

hall effect sensor and the piezo valve modulator to the main PCB

assembly.

Driver Module Assembly Replacement

To replace the driver module assembly, refer to Figures 11-15 and 25

and proceed as outlined below. The following tools are required:

• Flatplateorbarabout

1

⁄8" thick

• Phillipsscrewdriver

• "nutdriver

c

WARNING: Observe precautions for handling electrostati-

cally sensitive devices.

1.

Make sure the valve is bypassed or in a safe condition.

2. Disconnect the power and air supply to the unit.

3. Remove the driver module cover (Figure 14), using a flat bar or

plate in the slot to turn the cover.

4. Remove the spool valve cover by removing the screw and slid-

ing the cover assembly backwards until the tab is clear of the

slot (Figure 12). The sheet metal cap, hydrophobic filter, and

O-ring should be removed with the spool valve cover. It is not

necessary to take these parts out of the spool valve cover.

5. Being careful not to lose the nylon washer, remove the Phillips-

head screw that attaches the driver module to the main housing

(Figure 13).

c

WARNING: Spool (extending from the driver module

assembly) is easily damaged. Use extreme caution when

handling spool and spool valve block. Do not handle the

spool by the machined portions of spool. The toler-

ances between the block and spool are extremely tight.

Contamination in the block or on the spool may cause

the spool to hang.

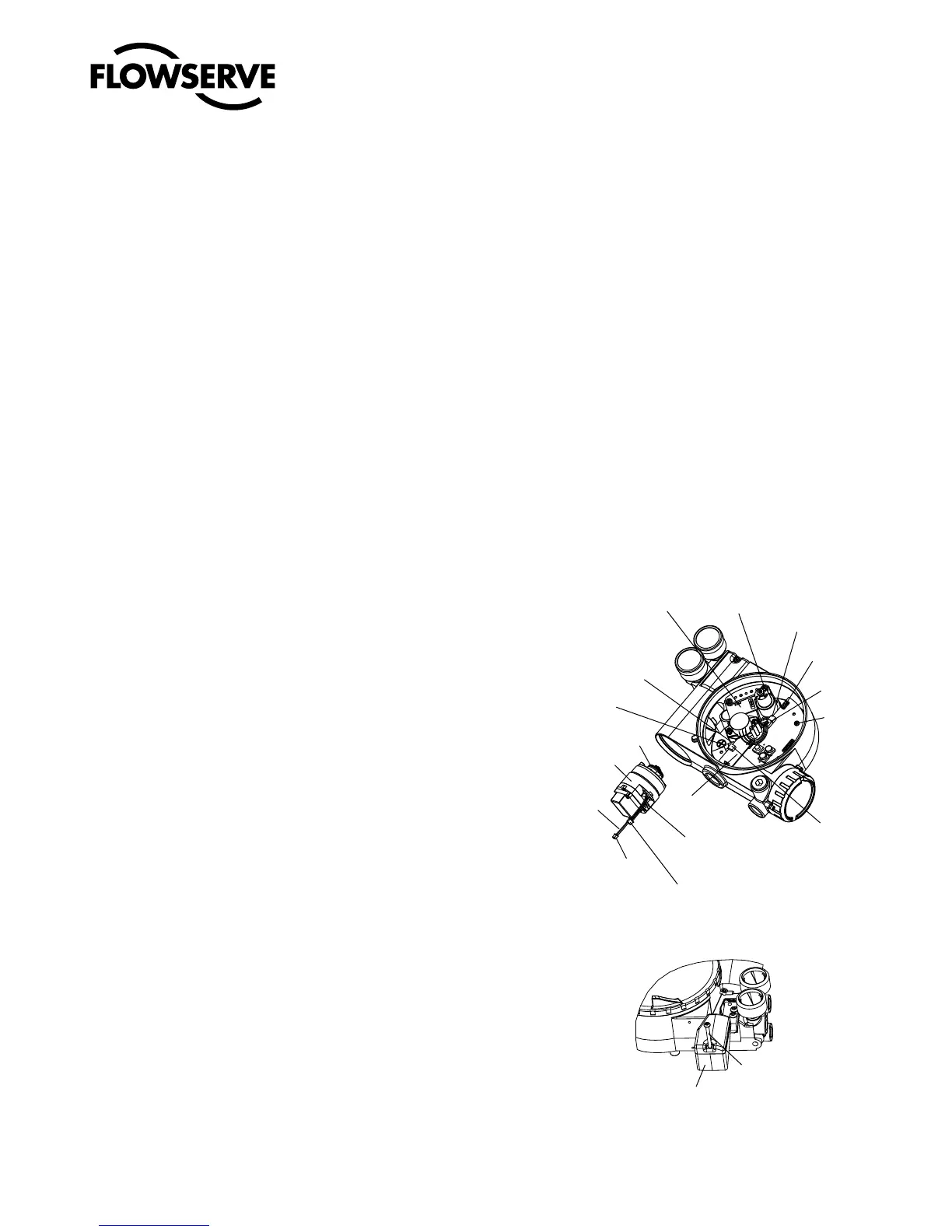

1SFTTVSF4FOTPS#PBSE

)BMM4FOTPS

$POOFDUJPO

1SFTTVSF

.PEVMBUPS

$POOFDUJPO

0SJOH

%SJWFS.PEVMF

"TTFNCMZ

"OBMPH

0VUQVU

#PBSE

$POOFDUJPO

"OBMPH

0VUQVU#PBSE

*OTUBMM#BSCFE'JUUJOHBGUFS

%SJWFS.PEVMFJTJOIPVTJOH

)BMM4FOTPS$POOFDUPS

1SFTTVSF.PEVMBUPS$POOFDUPS

1PTJUJPOXJSFT

UPUIFSFBS

PG.PEVMBUPS

3FHVMBUPS

1SFTTVSF4FOTPS

#PBSE$POOFDUJPO

6TFS*OUFSGBDF

#PBSE$POOFDUJPO

4UFN1PTJUJPO

4FOTPS

$POOFDUJPO

.BJO1$#

3FUBJOJOH

4DSFX

Figure 11: Driver Module Assembly

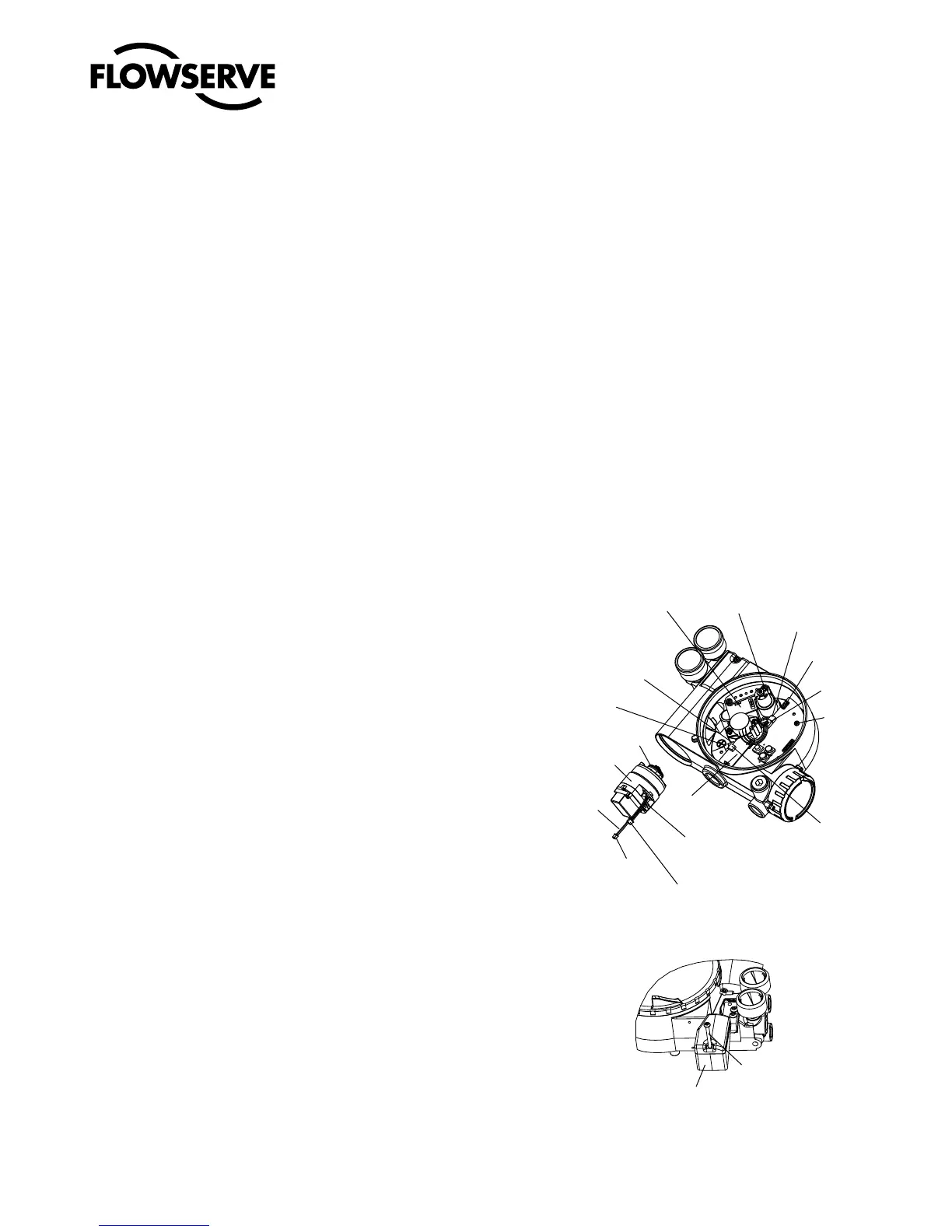

Figure 12: Spool Valve Cover Assembly

Loading...

Loading...