®

User instructions - Digital Positioner 3200MD LGENIM0059-01 10/08

39

*Contact factory before specifying this option

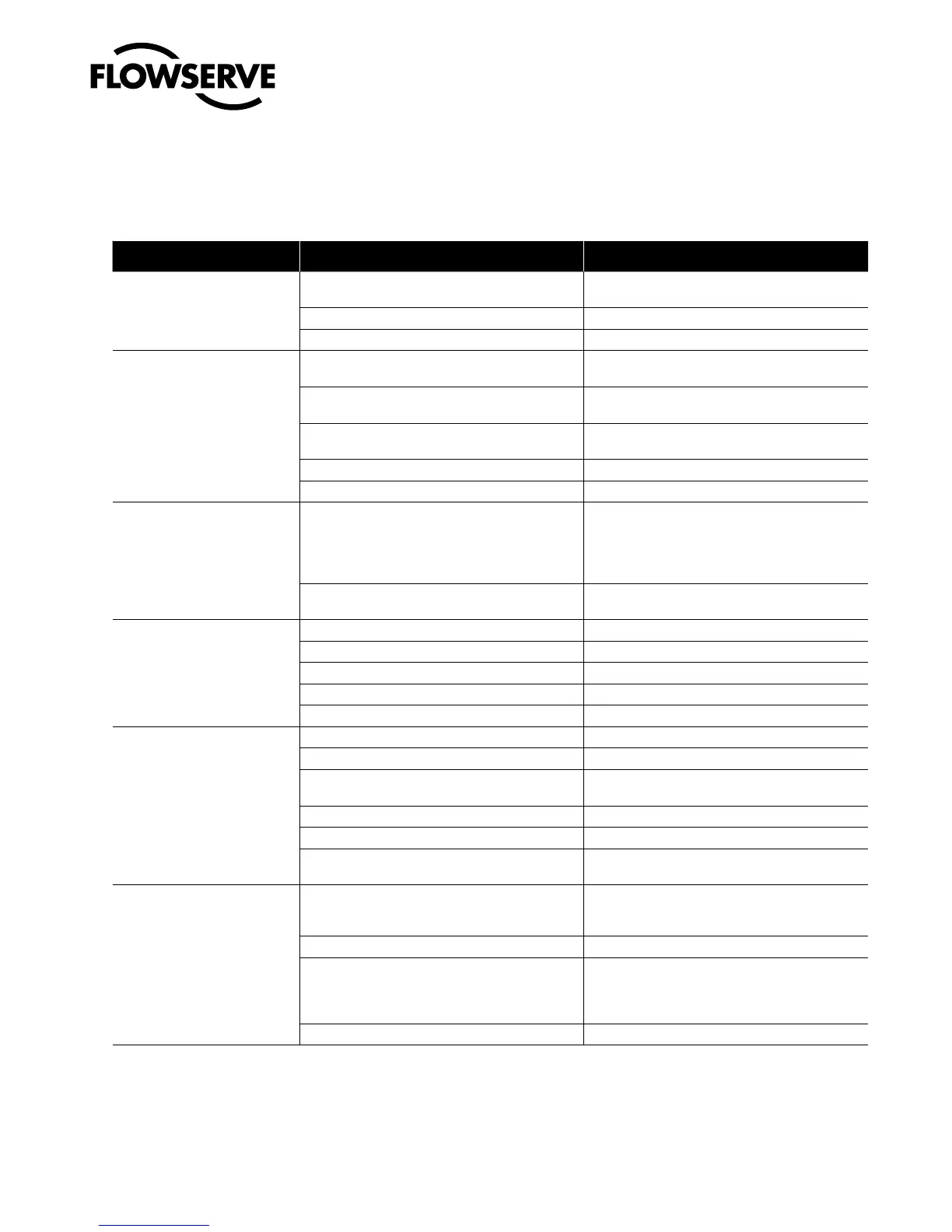

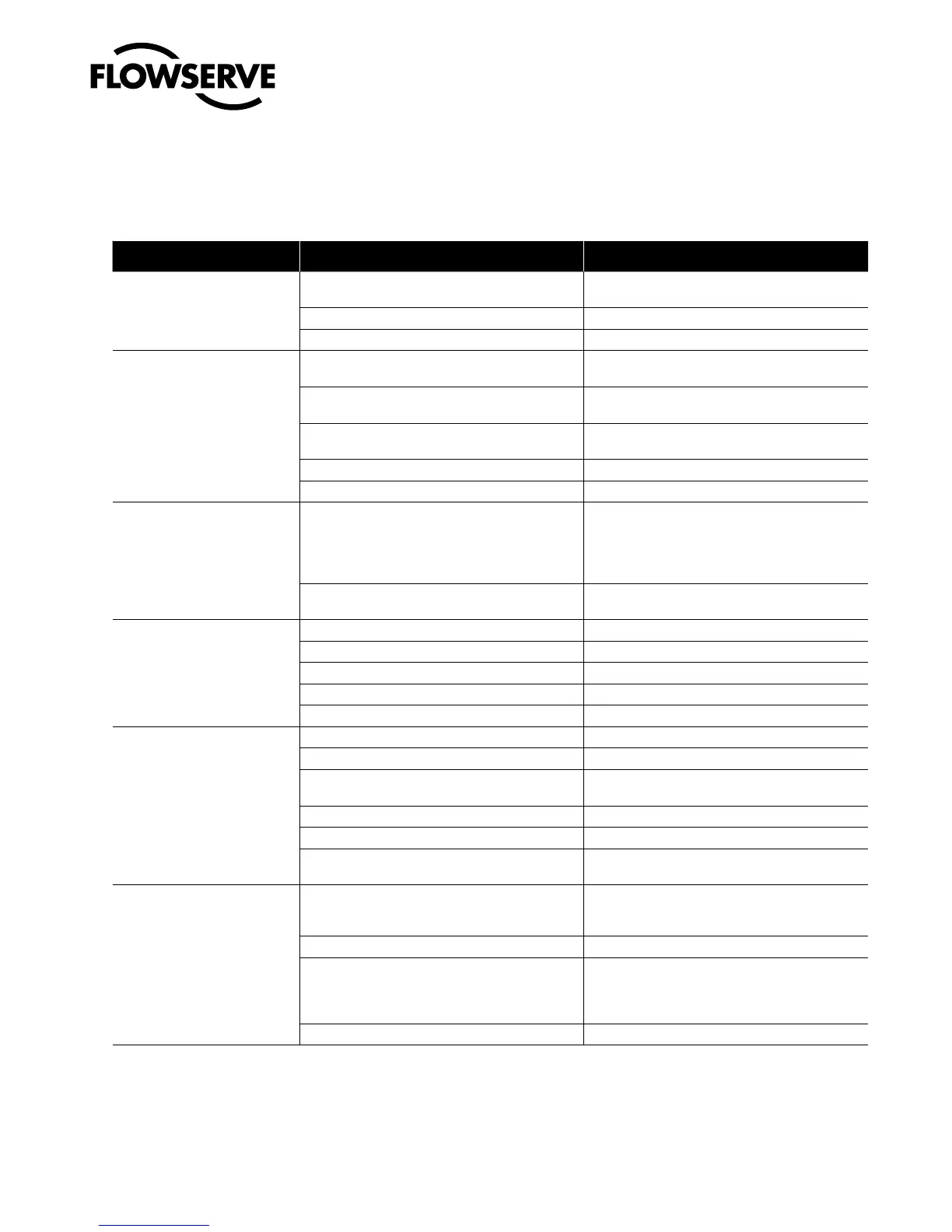

15 Troubleshooting

Failure Probable Cause Corrective Action

No LED is blinking

Current source below 3.6 mA without AO card or 3.7 mA

with AO card

Verify current source is outputting at least 3.6 mA with

AO card or 3.7 mA with AO card

Incorrect wiring polarity Check wiring for correct polarity

Voltage of current source is not high enough Verify that current source can supply at least 10 V

Erratic communications

Current source bandwidth not limited to 25 Hz

Maximum allowable current source rate of change is

924 mA per second

Maximum cable length or cable impedance exceeded

Check cable conduction size, length and capacitance.

Refer to Section 6.4, “Cable Requirements”

HART modem connected to PC RS-232 port not receiv-

ing enough power

Verify laptop battery is not low

Interference with I.S. barrier Must use HART-compatible I.S. barrier

Current Source stripping (filtering) HART signal. Use the HART filter (VHF) available from Flowserve

Unit does not respond to analog

commands

Unit is in digital command mode

Switch to analog command mode by doing a Command

Source Reset from the local interface or with a handheld

communicator or ValveSight (please refer to Section 7.9,

“Command Source Reset,” or the quick start guide for

detailed instructions).

Error occurred during calibration

Check blink codes on positioner and correct

calibration error. Recalibrate

Valve position reading is not

what is expected

Positioner tubing backwards Re-tube the actuator

Stem position sensor mounting is off 180° Remount position sensor

Stroke not calibrated Perform QUICK-CAL

Tight shutoff (M.P.C)* is active Verify settings using PC or handheld software

Customer characterization or soft stops active Verify customer characterization and soft stops

Position is driven fully open or

closed and will not respond to

command

Stroke not calibrated Check DIP switch settings and calibrate valve stroke

Inner-loop hall sensor not connected Verify hardware connections

Wrong air action entered in software

Check ATO (Air-to-open) and ATC

(Air-to-close) settings. Recalibrate

Actuator tubing backward Verify ATO/ATC actuator tubing

Electro-pneumatic converter malfunctioning Replace electro-pneumatic converter

Control parameter inner-loop offset is too high/low

Adjust inner-loop offset and see if proper control

resumes

Sticking or hunting operation of

the positioner

Contamination of the driver module

Check air supply for proper filtering and meeting ISA

specifications ISA-7.0.01. Check the spool valve for

contamination

Control tuning parameters not correct Adjust gain settings using local gain switch

Packing friction high

Enable the stability DIP switch on the local interface

and recalibrate. If problem persists, enable pressure

control with handheld communicator or ValveSight and

recalibrate

Corroded or dirty spool valve Disassemble and clean spool valve

*M.P.C.: Minimum position cutoff

Loading...

Loading...