temperature of a shiny object you can compensate by covering the surface to be

measured with masking tape or flat black paint. Allow time for the tape or paint to

reach the same temperature as the material underneath. Measure the temperature of

the taped or painted surface. That is the true temperature.

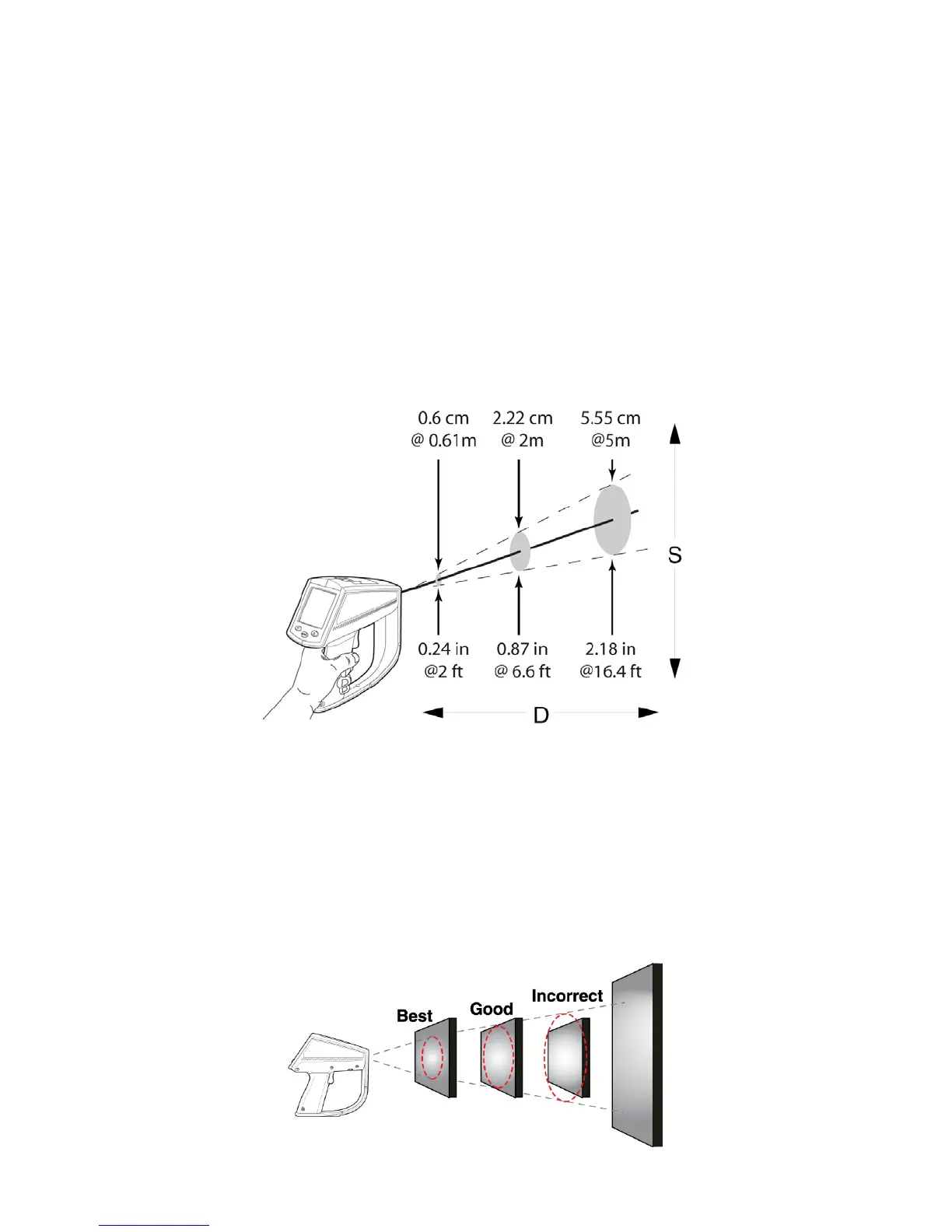

Distance to spot ratio

The optical system of an infrared thermometer collects the infrared energy from a

circular measurement spot and focuses it on the detector. Optical resolution is

defined by the ratio of the distance from instrument to the object compared to the

size of the spot being measured (D:S ratio). The larger the ratio number the better

the instrument’s resolution, and the smaller the spot size that can be measured. The

laser sighting included in some instruments only helps to aim at the measured spot.

A recent innovation in infrared optics is the addition of a Close Focus feature, which

provides accurate measurement of small target areas without including unwanted

background temperatures.

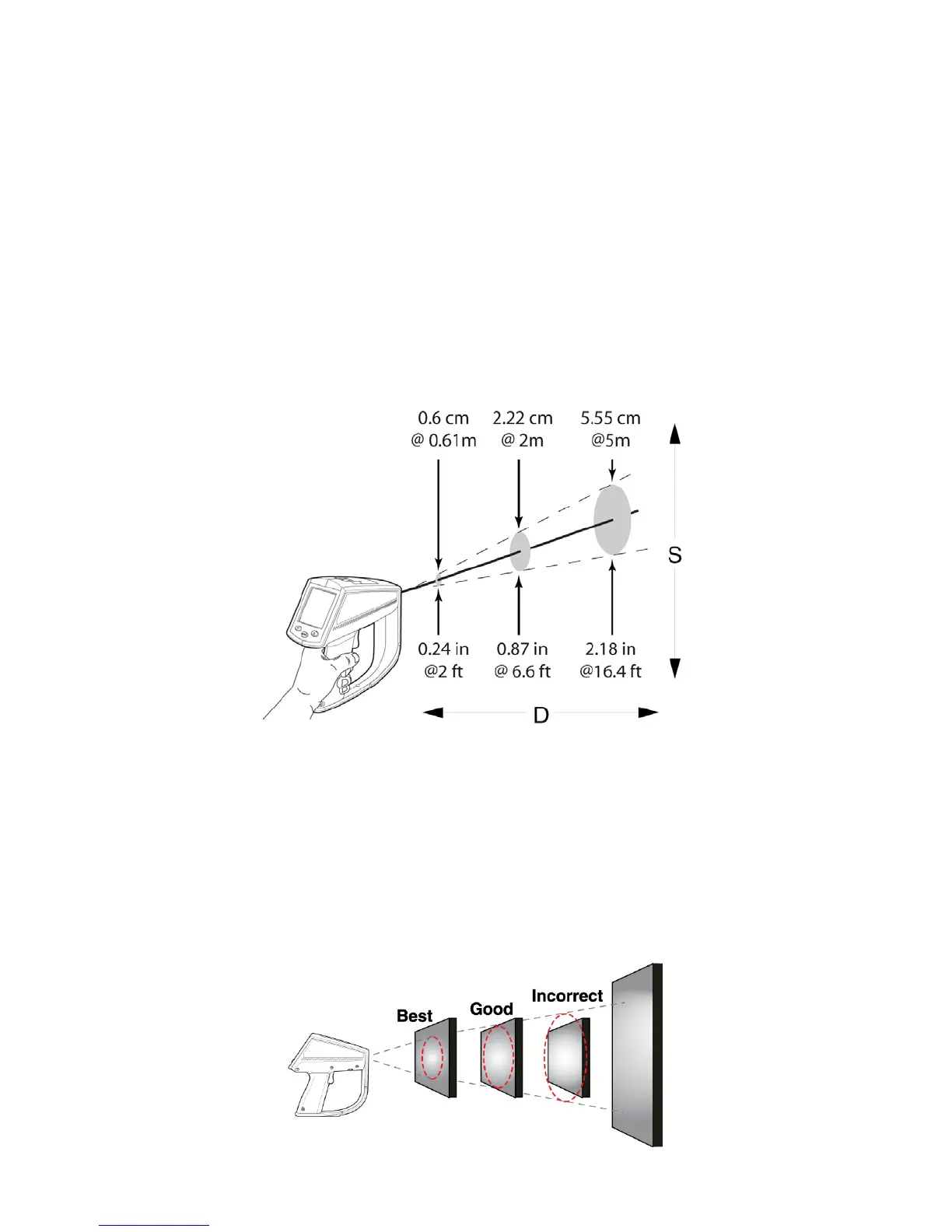

Field-of-view.

Make sure that the target is larger than the spot size the unit is measuring. The

smaller the target, the closer you should be to it. When accuracy is critical make sure

Jan 31st, 2005

- 94 -

Loading...

Loading...