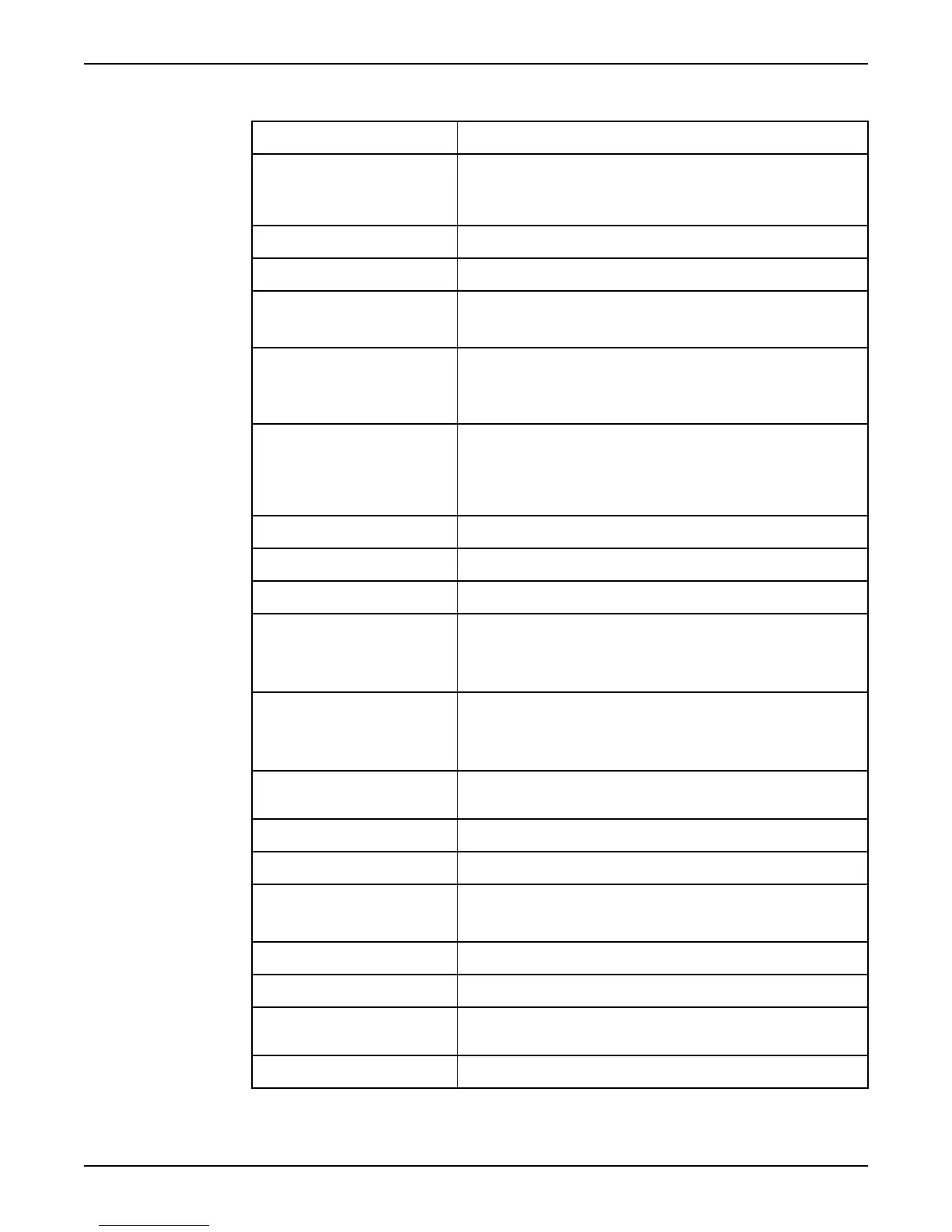

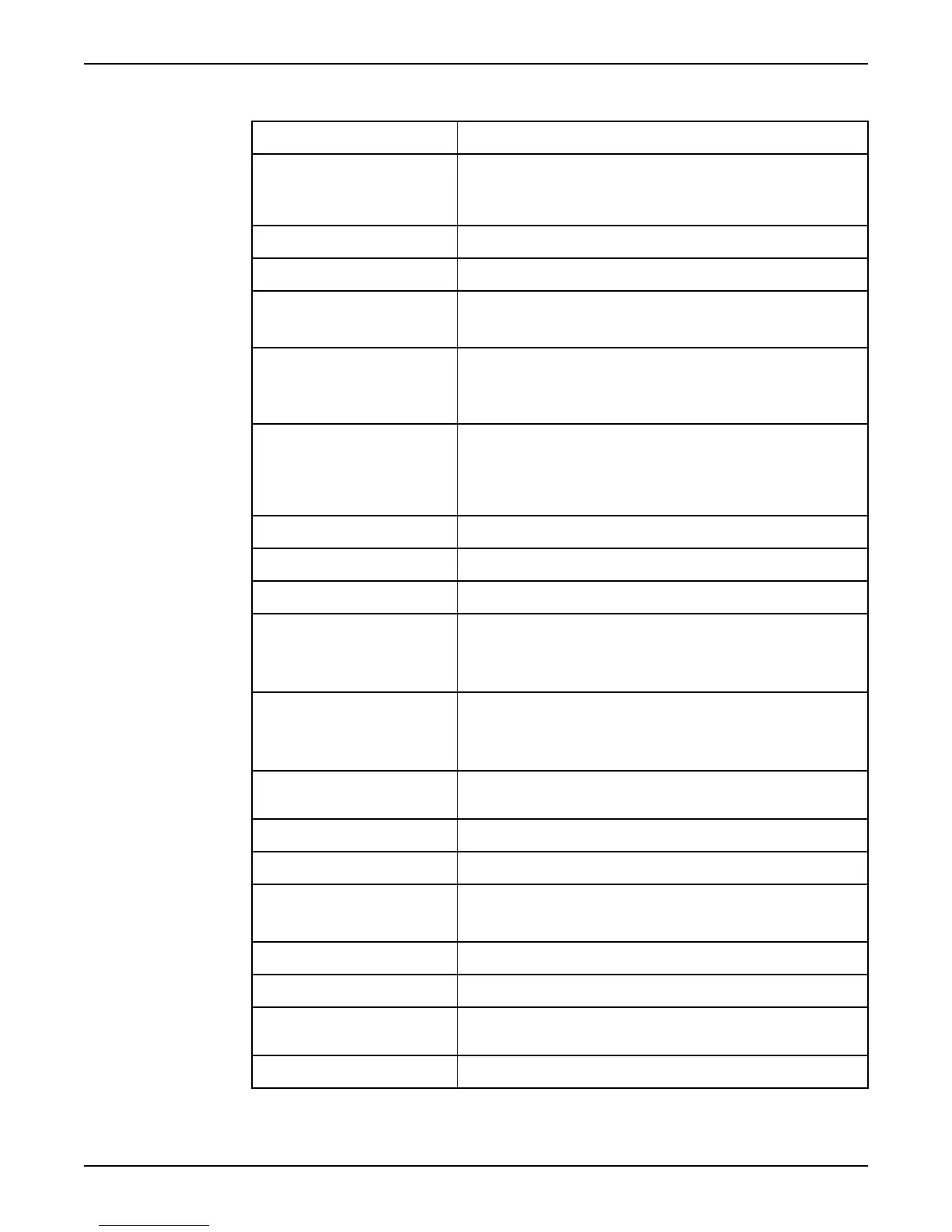

Inspection

Service item Action

Cable

1. If the outer jacket is damaged, replace the cable.

2. Check that the cables do not have any sharp bends and are not

pinched.

Connection to power Check that the connections are properly tightened.

Electrical cabinets Check that they are clean and dry.

Impeller

1. Check the impeller clearance.

2. Adjust the impeller, if necessary.

Inspection chamber

1. Drain all liquid, if any.

2. Check the resistance of the leakage sensor.

Normal value approx.1200 ohms, alarm approx. 430 ohms.

Insulation Use a megger maximum 1000 V.

1. Check that the resistance between the earth (ground) and

phase lead is more than 5 megohms.

2. Conduct a phase-to-phase resistance check.

Junction box Check that it is clean and dry.

Level regulators Check the condition and functionality.

Lifting device Check that local safety regulations are followed.

Lifting handle

1. Check the screws.

2. Check the condition of the lifting handle.

3. Replace if necessary.

O-rings

1. Replace the oil plug O-rings.

2. Replace the O-rings at the entrance or junction cover.

3. Grease the new O-rings.

Overload protection and other

protections

Check the correct settings.

Personnel safety devices Check the guard rails, covers, and other protections.

Rotation direction Check the impeller rotation.

Seal housing

1. Fill with new coolant, if necessary.

2. Check that the freezing point is lower than -13°C (9°F).

Terminal board Check that the connections are properly tightened.

Thermal contacts Normally closed circuit; interval 0–1 ohm.

Thermistor Check the resistance is between 20–250 ohms and the measured

voltage is maximum 2 V DC.

Voltage and amperage Check the running values.

Maintenance

Flygt 3153 Installation, Operation, and Maintenance Manual 43

Loading...

Loading...