30

7.4.2 Resolve Print Failures and Errors

Print failures can manifest in dierent ways and originate from dierent causes. Check the

model’s configuration in PreForm, the cleanliness of the optical surfaces, and the printer’s

operating condition according to 6 Maintenance and 7 Troubleshooting, including the

proposed solutions below.

If print failures persist after following these steps, contact Formlabs or a certified service

provider for additional guidance. In order to introduce a known good variable to isolate any

printing issues, run a Formlabs test print, for which the file is available on support.formlabs.

com. Provide clear, focused photographs of the test print to help diagnose the issue.

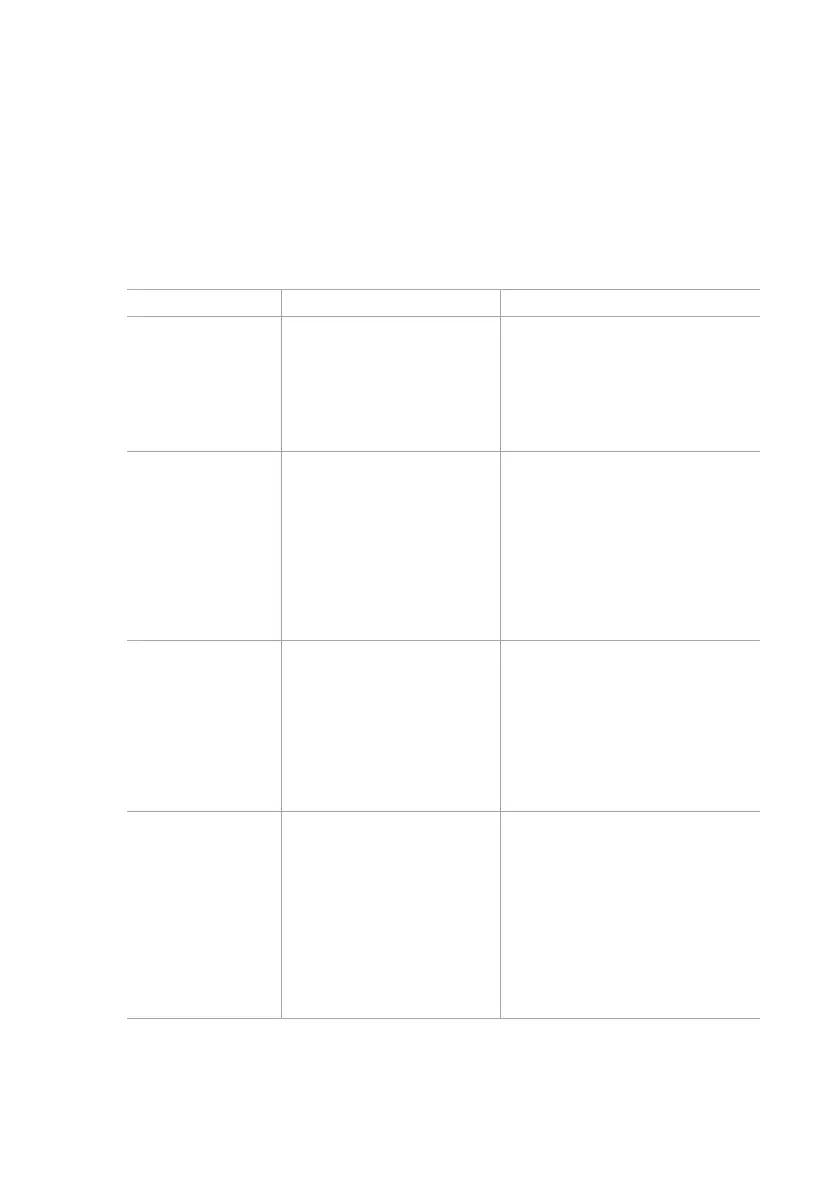

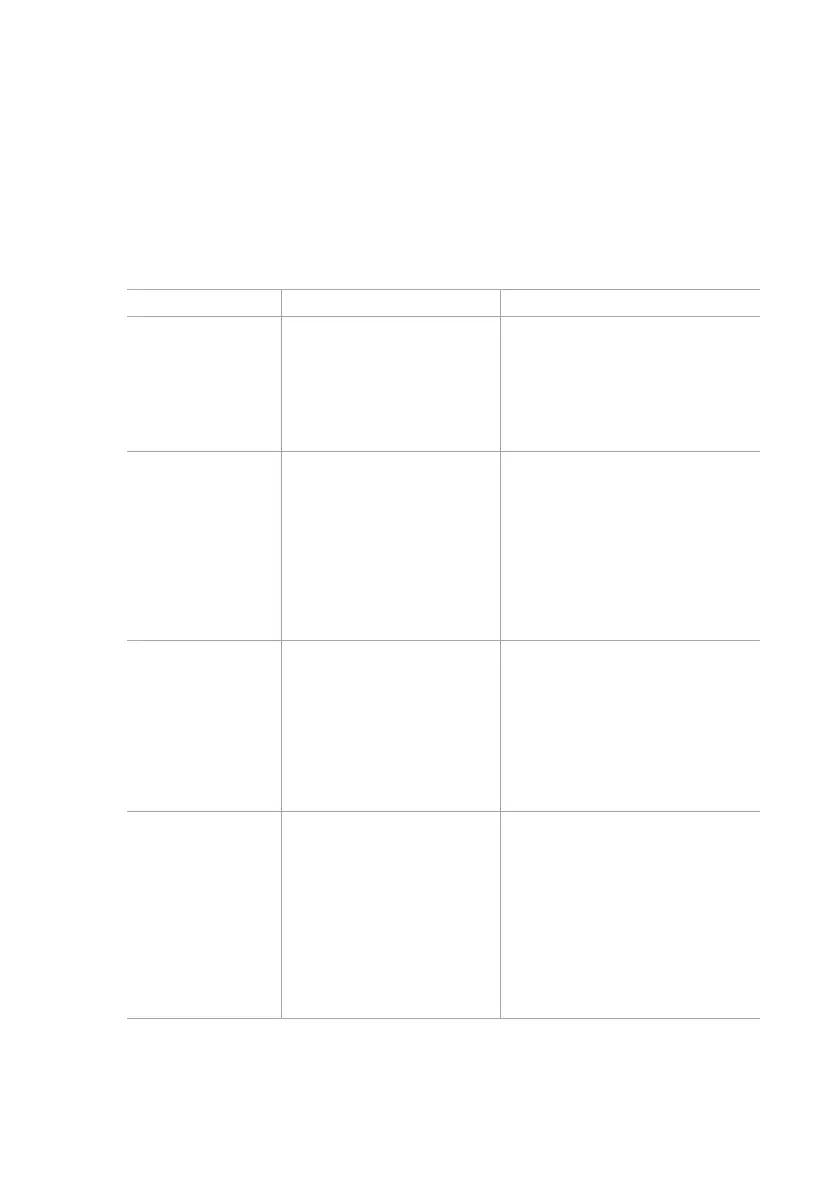

Error Cause Solution

Delamination

Peeling or separation

between printed layers

Pieces of cured parts

floating in the resin tank

Model orientation, layout, and/or

support issues

A print that has been paused for

a long time

An older resin tank

A loose build platform

Contaminated optical surfaces

Consider the following:

• Check the model in PreForm.

• Check for pauses in printing.

• Check the resin tank for debris

or damage.

• Check cleanliness of optical surfaces.

• Check the build platform’s stability.

Non-Adherence

Prints either partially

attached to or

completely non-existent

on the build platform

Printing without supports

The first layer of the part on the

build platform is too small to

withstand peel forces.

Debris/damage in resin tank

Contaminated optical surfaces

Build platform height requires

adjustment

Consider the following:

• Print with a base and supports.

• Check the print’s surface area.

• Check the resin tank for debris

or damage.

• Check cleanliness of optical surfaces.

• Check the build platform height.

• Decrease (“-”) the Z Oset value to

lower the build platform closer to the

resin tank bottom.

Overcompression

The base printed onto

the build platform is

thinner than expected

and/or very dicult

to remove.

The initial layers fail to cure

properly, due to insucient

space between the build platform

and the film in the resin tank.

Consider the following:

• Increase the base height in PreForm’s

advanced settings.

• Check the build platform height.

• Increase (“+”) the Z Oset value to

raise the build platform further away

from the resin tank bottom. Raising

the build platform provides more

space for the base to build.

Poor Surface Finish

Cured or partially cured

resin forms thin, shelf-

like structures that hang

horizontally from a print.

OR

A rough - uneven or

bumpy - surface texture

forms on one or both

sides of an otherwise

successful print.

Diused laser light spreads

the cure area beyond the

appropriate limits for each layer

outline, due to:

Expired resin;

Debris/damage in the resin tank;

Contaminated optical surfaces;

or, Restricted resin flow due to

improper model orientation or

overly dense supports

Consider the following:

• Check the resin’s shelf life.

• Check the resin tank for debris

or damage.

• Check cleanliness of optical surfaces.

• Check for restricted resin flow.

Loading...

Loading...