Glossary | 35

10. Glossary

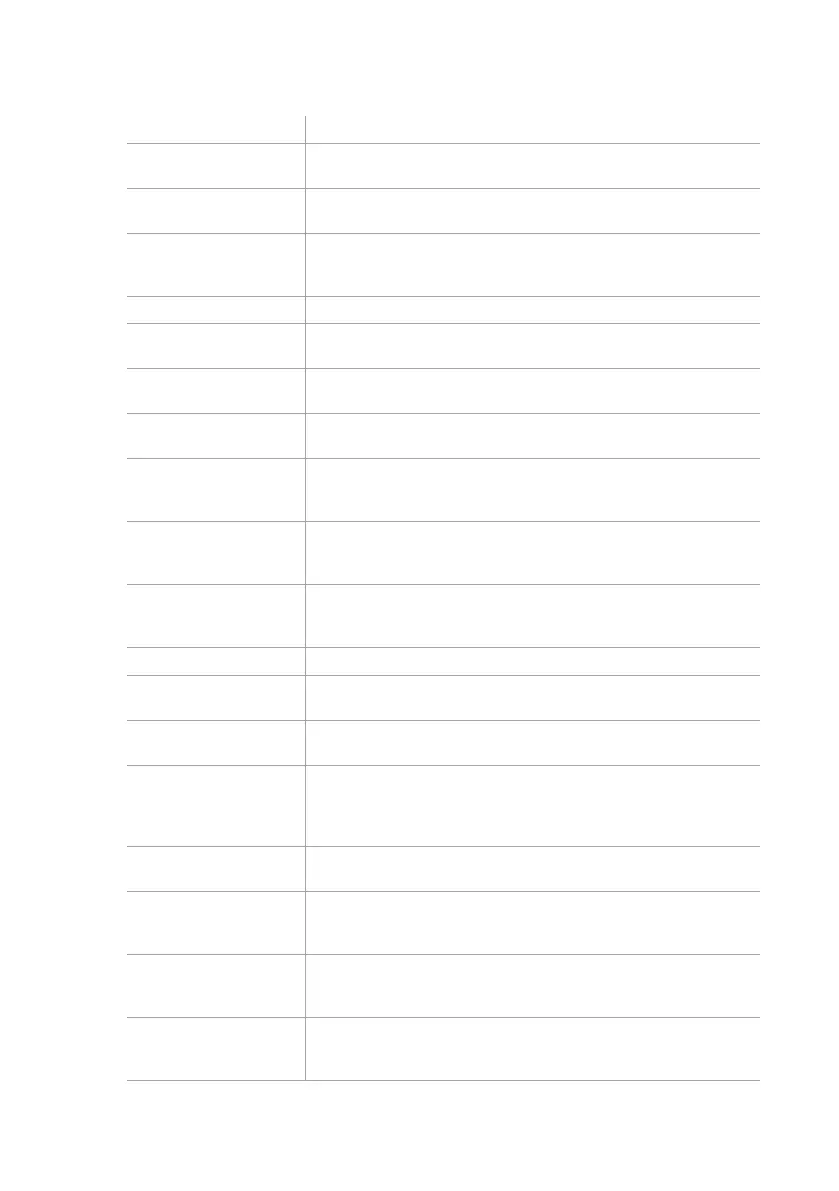

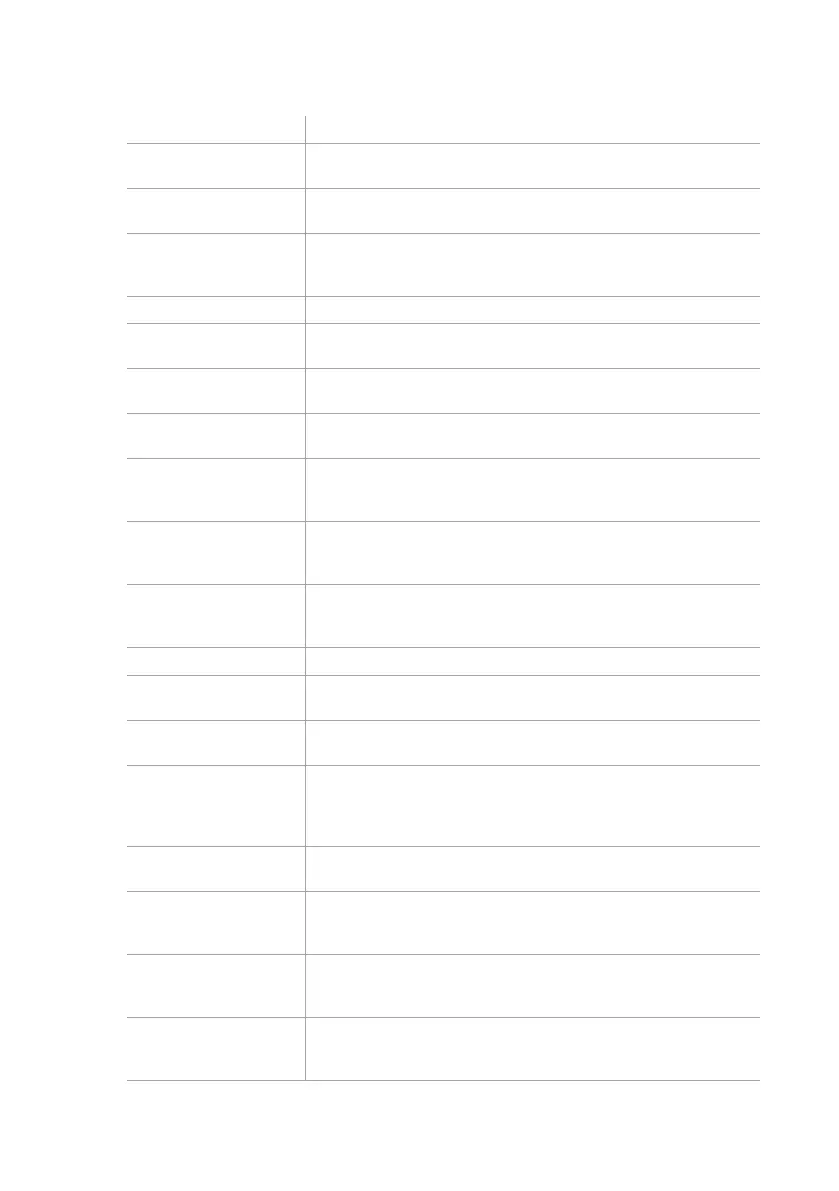

Term Meaning

Cover

The upper enclosure, made of strong, amber-tinted material, blocks

exposure to the laser and protects the resin from curing due to ambient light.

Bite valve This flexible seal regulates resin dispensing. Resin flows out when the

cartridge dispense arm squeezes the valve open.

Build Platform - see also,

platform lock

The aluminum base provides a surface for prints to attach to. Over time,

the build platform will develop scratches from part removal, which can

assist with print adherence.

Build Platform carriage The carriage is the metal arm that the build platform slides onto.

Build Platform sensor Inserting the build platform triggers a limit switch in the Z-axis. The printer

detects when the build platform is properly installed in its home position.

Cartridge (Resin Cartridge) This container holds the resin before dispensing into the resin tank.

Shake the cartridge periodically to keep resin well mixed.

Cartridge dispense arm This plastic hook presses against the bite valve to dispense resin out of

the cartridge into the resin tank.

Cartridge ID chip An Electrically Erasable Programmable Read-Only Memory (EEPROM) chip

programmed with the resin type is attached to the cartridge skirt. This chip

communicates to the printer via spring fingers on the cartridge floor.

Cartridge spring fingers Two electrical contacts comprise the spring fingers located on the

cartridge floor. The physical contact establishes an electrical connection

with the cartridge ID chip to detect the cartridge.

Display assembly The display assembly contains the touchscreen and the display

circuit board. A ribbon cable connects the display assembly to

the motherboard.

Display cable A flat, flexible cable connects the display assembly to the motherboard.

Ethernet port The Form 3 can connect to a network via Ethernet. The port is connected

to the motherboard and can be accessed from the back of the machine.

Fans A heating fan blows air across the heater into the resin tank. Cooling

fans pull warm air away from electronic components.

Film A durable, dual-layer film comprises the bottom surface of the resin tank.

Parts print in the resin-filled gap between the film and the build platform.

The quality of printed parts depends on the film being clean and clear of

damage and debris.

Film tensioner A motor pulls outward on the tank side walls to create a taut film surface

in the resin tank.

Float A hinged bobber rests on the surface of the resin. The aluminum

counterweight passes in front of the LevelSense board to determine the

amount of resin in the tank.

Heater The resin in the resin tank is heated by hot air blown out of the tower

behind the resin tank. The warm air in the print chamber heats the resin,

and the air temperature is sensed by a thermal sensor at the air intake.

Interlock magnets The interlock sensor detects these magnets to determine when the cover

is closed. This safety mechanism triggers the “cover open” message on

the touchscreen and disables the laser when the cover is open.

Loading...

Loading...