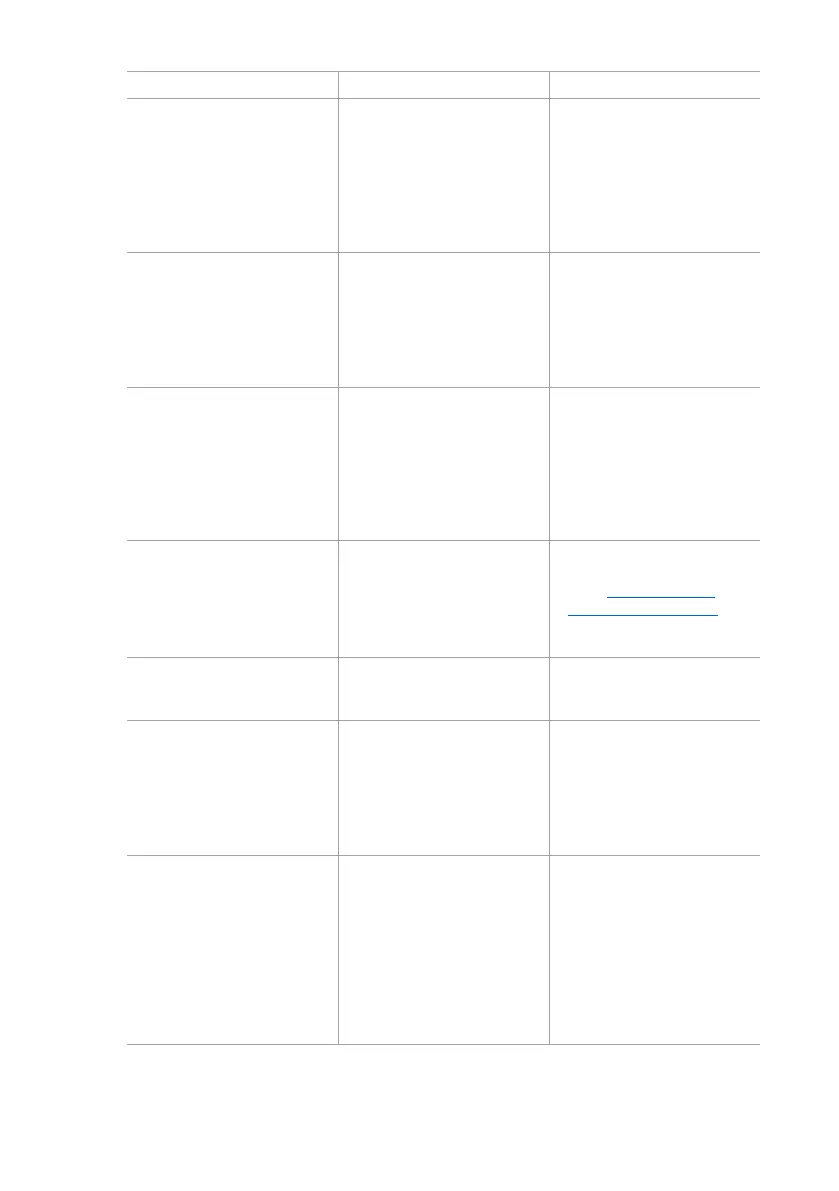

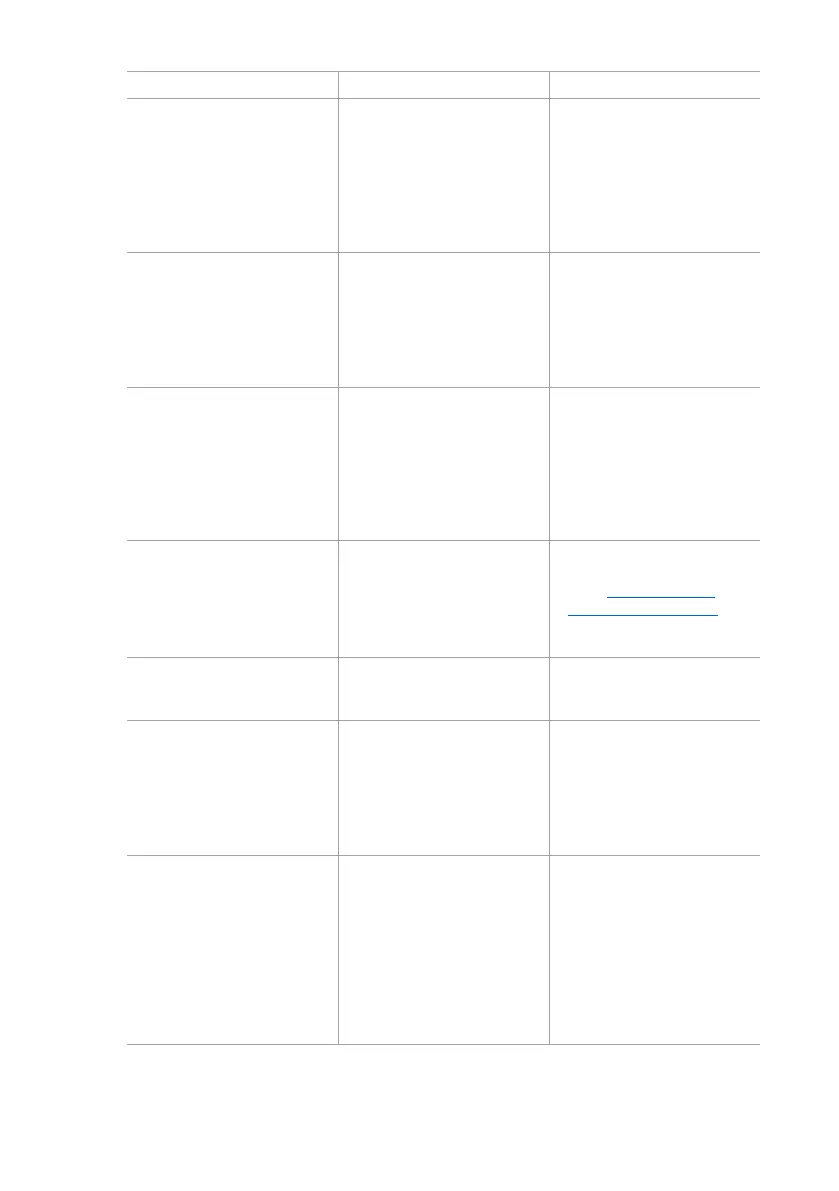

Troubleshooting | 53

Error Cause Solution

Hard cake

• Unsintered powder fused into

a sti cake

• Diculty separating the part

from the unsintered powder

• Poor underlying surface finish

and loss of small negative

features

Bed temperature is too high. Check whether the IR sensor

housing has any laurolactam

built up in the sensor field of

view. Refer to section 6.4.2

Cleaning the IR sensor

housing for more information.

Warping

• Large scale curvature or a part

or section of parts

• Deviation from flatness

• Straightness spec

• Improper cooling procedure;

warping can occur during a

print if the part is allowed to

cool non-uniformly or if the

part is removed while still hot

• Parts printed too close to the

build chamber walls

1. Wait for parts to cool to

near room temperature

prior to removal from the

build chamber.

2. Move parts away from the

build chamber walls.

Pitting

• Surface imperfections on the

top-most surface on parts,

typically on small cross-

sectional regions

• In some cases, a hole that is

deeper or several layers thick

Bed temperature is too high. Check whether the IR sensor

housing has any laurolactam

built up in the sensor field of

view. Refer to section 6.4.2

Cleaning the IR sensor housing

for more information.

Melting

The powder on the surface of the

print is blackened due to melting.

Heaters heated the powder to

above its melting temperature.

The heaters or the IR sensor

may be malfunctioning.

Contact Formlabs Support or

a certified service provider for

additional guidance and provide

diagnostic logs.

Delamination

A sintered layer failed to adhere

to a previously sintered layer.

• Insucient laser power

• Build chamber Z-motor

malfunction

Inspect the optical surfaces.

Fragile parts

• Parts with excessively low

strength

• Parts occasionally have a

lighter color and a more

granular surface texture than

normal

Insucient sintering due to

attenuated laser power.

Inspect the optical surfaces.

Poor, mottled surface finish on

vertical surfaces

• Ratio of recycled to unused

powder is too high

• Grain size of recycled

powder is higher than unused

powder, causing variation

in melt temperature and

viscosity, leading to uneven

sintering in the bulk of the

model and poor surface finish

on the outside of the model

• Increase powder refresh rate

OR

• Dispose of degraded powder

Loading...

Loading...