40

• Alconox

The recommended cleaning agent for removing deposits of laurolactam and other o-

gassing stains from the printer’s optical components. It is the first cleaning agent to be used,

followed promptly by distilled water and ethanol.

• Compliant vacuum that is grounded and bonded (e.g., Class II, Division 2 vacuum)

Certified for use with materials whose fine particles present an explosive risk when in the

vicinity of potentially malfunctioning electrical equipment. Used to regularly remove loose

powder from the workspace of the Fuse 1 and Fuse Sift.

• Distilled water

The second agent used for cleaning the printer’s optical components.

• Ethanol

The last recommended denaturing agent used for cleaning the printer’s optical components.

• PEC*PADs

Disposable lint-free, non-woven microfiber cloths for cleaning the printer’s optical

components. Do not reuse a PEC*PAD; dispose of after each use, even when cleaning the

windows on the optical cassette with the same cleaning agent.

• Polyester cloth swabs

Disposable lint-free polyester cloth swabs with either orange or blue plastic handles for

cleaning the IR sensor and camera lens. Do not reuse a polyester swab—dispose of after

each use.

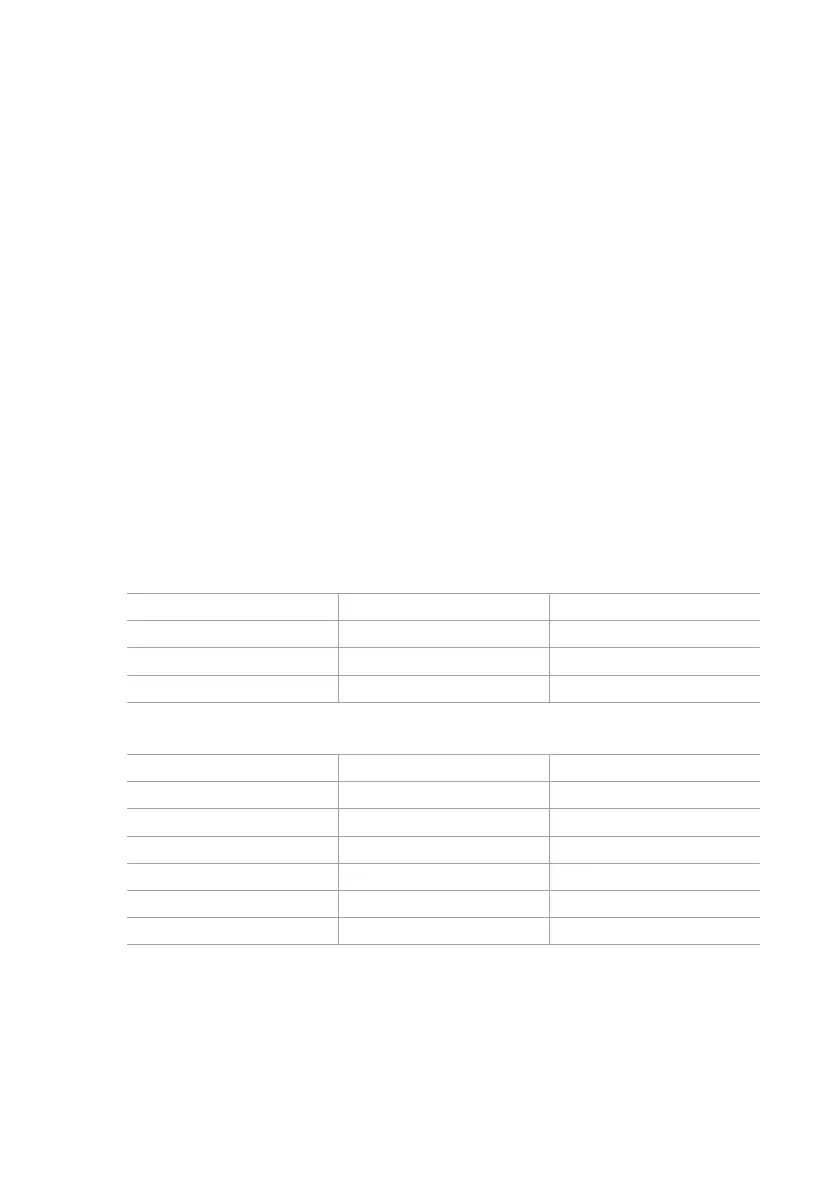

6.2 Inspection and maintenance

6.2.1 Before each use

Inspect Refer to Section

Installation environment Operational environment 5.1

Optical cassette Cleaning the optical cassette 6.3.1

IR sensor lens Checking the IR sensor 5.4.4

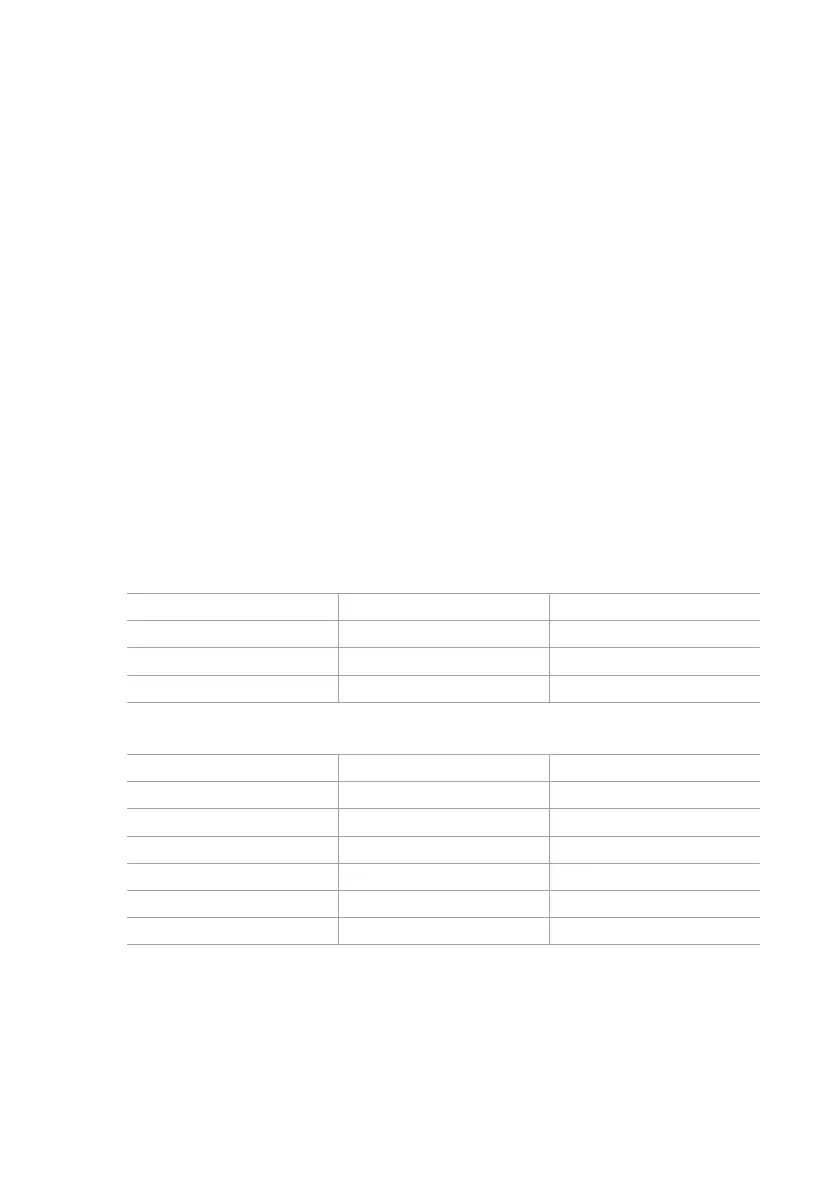

6.2.2 Periodic maintenance

Inspect Refer to Section

Camera lens Cleaning the camera lens 6.4.1

IR sensor housing Cleaning the IR sensor housing 6.4.2

Exhaust filter Cleaning the exhaust filter 6.4.3

Intake filter Cleaning the intake filter 6.4.4

Print enclosure Cleaning the print enclosure 6.4.5

Exhaust lines Purging the exhaust lines 6.4.6

6.3 Tasks between uses

Sintering powder results in the production of o-gases and laurolactam, which collect on various

components in the print enclosure and air system. In order to preserve the accuracy and reliability

of the product, it is important to regularly check and clean several components and assemblies.

Loading...

Loading...