Page 9

2.0 Safety

2.1 Safety Working

Before using this chipper, make sure that you are trained and fluent in its operation.

Know the location of and how to use all the safety features. Know how to control the

feed and stop the chipper in an emergency. Be familiar with the hazards and safe

working practices to prevent injury and damage to property and chipper. Also be

aware of the legal restrictions for personnel and towing with vehicles.

• The minimum age for service personnel is 18

years. Personnel aged 16 can use the

chipper for training under supervision by a

suitably trained person of 18 years or over.

• Operators and personnel working with this

chipper must not be under the influence of

alcohol, drugs or medication that would impair

judgement, concentration or reaction times.

Excessive tiredness is also a risk.

• In use, woodchip and debris are ejected with

considerable force from the chute and can

travel up to 10m. Make sure the chute directs

woodchip to a safe location so that no one can

be harmed or property damaged. Do not allow

discharge to be directed onto roads or public

rights of way.

• Maintain a 10m exclusion zone around the

chipper and clearly mark if in a public area.

Keep this area free of material build up.

• Make sure the chipper is on even, level and

stable ground and cannot move or topple

when in use. Use wheel chocks if necessary.

• Keep children and animals well away from the

working area.

• The chipper operator must wear protective

equipment:

▪ Chainsaw safety helmet (EN 397) with

mesh visor (EN 1731)

▪ Correctly rated ear defenders (EN 352)

▪ Work gloves with elasticated wrist bands.

▪ Steel toe cap boots (EN345-1)

▪ Close fitting heavy duty non-snag clothing.

Hi-viz clothing (EN 471) if needed.

▪ Protect breathing with a face mask if

appropriate. Some plant material can give

off harmful dust and poisonous vapours.

This may cause respiratory problems or

serious poisoning. Check the material to

be processed before starting.

• DO NOT wear rings, bracelets, watches,

jewellery or anything that could be caught on

the material being fed and draw you into the

chipper.

• All personnel operating or feeding material into

the chipper must wear heavy duty non-snag

clothing to help prevent being caught on

material and drawn into the chipper. The feed

mechanism of this chipper uses high powered

hydraulic motors to drive sharp toothed rollers

that feed material into the cutting blades. DO

NOT take risks with it. NEVER ASSIST ANY

MATERIAL INTO THE FEED ROLLERS WITH

HANDS OR FEET. Use the wooden paddle or

further long material if necessary.

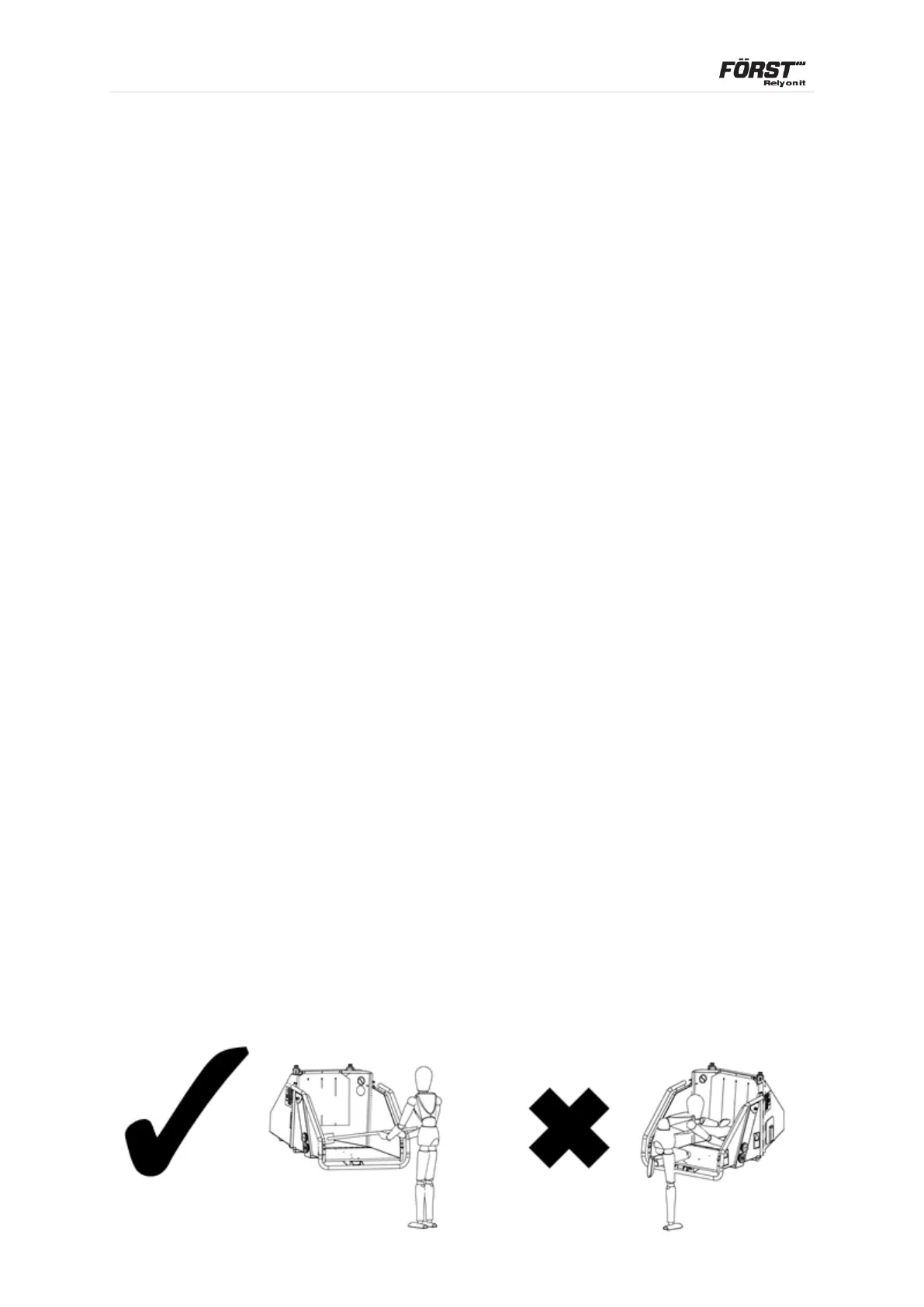

• Never climb onto the hopper area while the

chipper is in operation.

• CAUTION! – Keep hands and feet outside the

hopper. Do not attempt to force material into

the chipper by hand – use a piece of wood if

necessary.

• Material can be forcibly ejected from the hopper

towards the operator. Ensure full head and

face protection is worn.

• Very twisted material should be trimmed into

manageable pieces. Failure to do this can

result in material extending outside the hopper,

moving aggressively side-to-side creating a

hazard to the operator.

• Do not try to force material over 150mm in

diameter into the chipper.

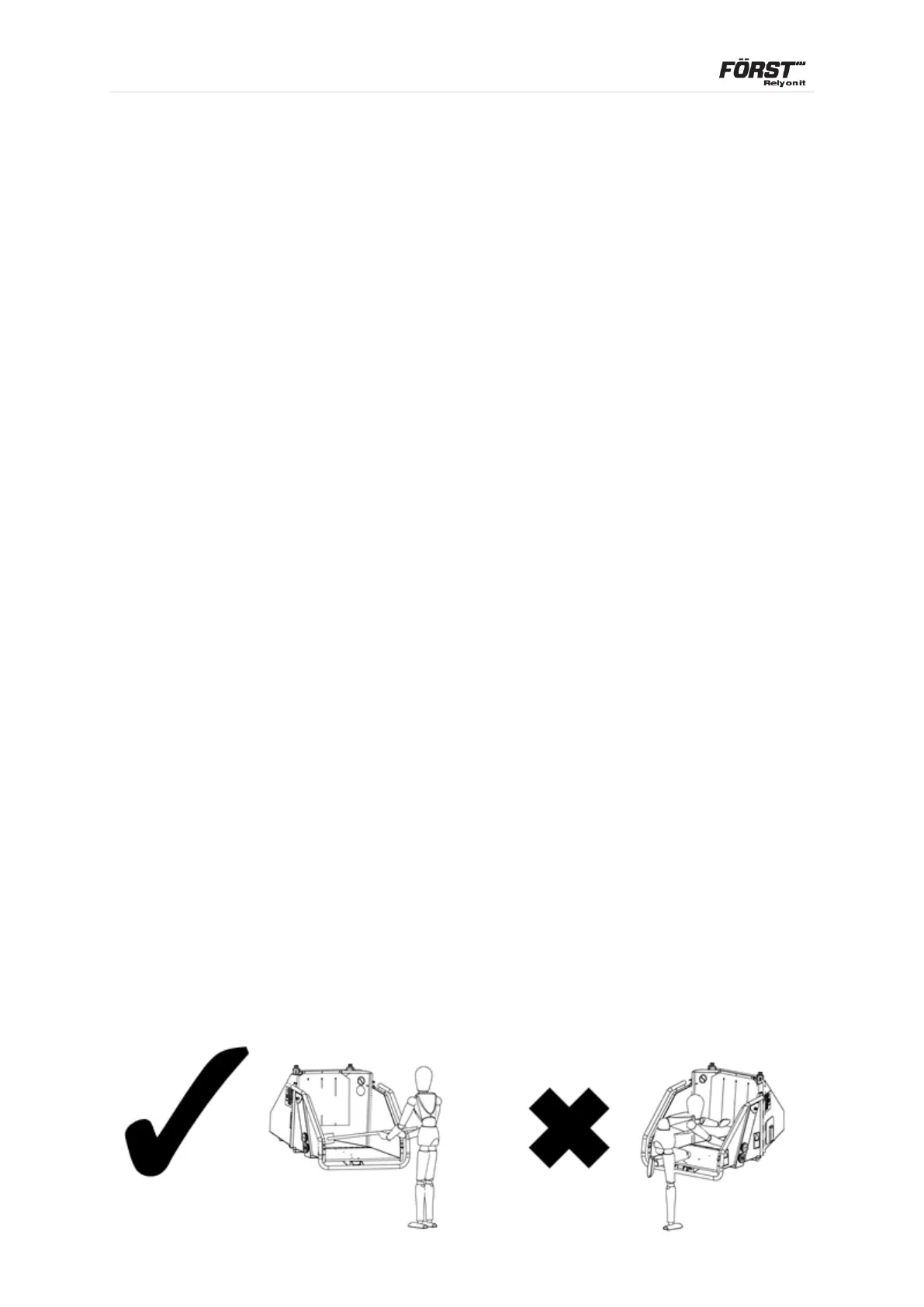

• Carefully site the chipper so operators can work

furthest from any local danger. For example,

on a road side, place chipper so operators work

on the verge and not in the road exposed to

traffic

Loading...

Loading...