The sample inside the check sample cell may have changed over time and the

proper action would then be to either replace the sample and/or to run a new check

sample definition to redefine the target values or even review the limits in

FossManager.

If the check sample is deemed to be OK and fresh, then running the Instrument

Diagnostics (from Care View) may give you an indication if something has

changed inside the instrument. Should the Instrument Diagnostics fail, then our

recommendation is to contact your local FOSS representative for assistance.

This refers to the artificial FOSS check sample. For info about the empty check

sample cell please see 4.5.1 Empty Check Sample.

The FOSS check sample available for NIRS DS3 / DS3 F is an artificial type check

sample intended for regular control of instrument stability. The frequency for

running the check sample is determined by your local quality routines.

Running the check sample is done in ISIscan Nova just as a normal sample is run.

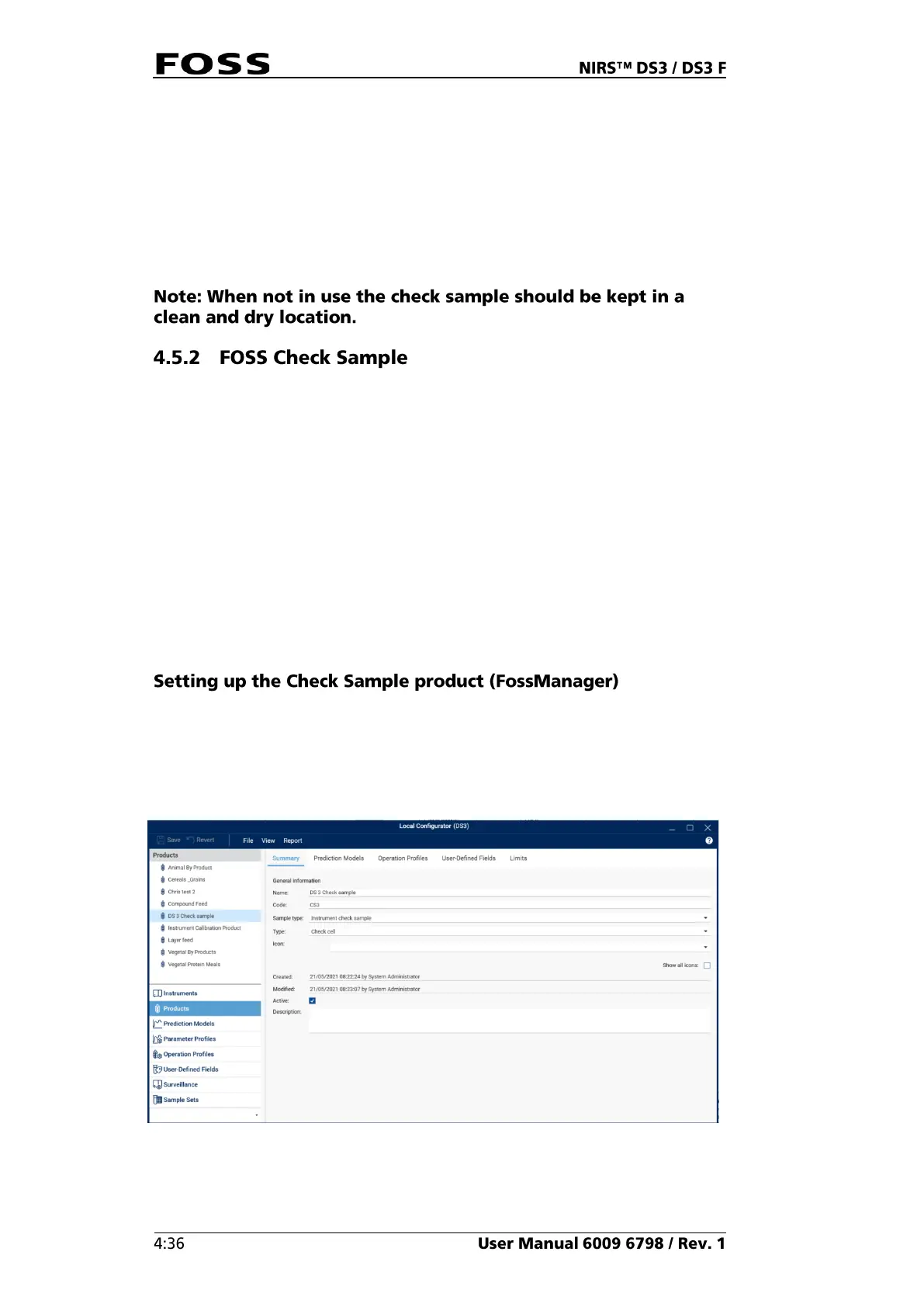

The check sample requires a check sample product to be set up in FossManager

with a proper operation profile and check sample prediction model.

The check sample product is delivered on a USB key together with the check

sample. This product will predict a specific distance in the check sample spectra

and the result is presented as a number without units. The result is compared to the

limits that have been set for the check sample product and a Warning (yellow) or

Error (red) will be displayed if the result is outside warning/action limits.

Before running the check sample you must import the check sample mcf file to the

software. It is delivered on a USB together with the check cell.

Import the .mcf-file as a product and the check cell product will be visible with

your other products.

Add an Instrument group to the product.

Fig. 103 Check sample setup in FossManager

If you are on the FossManager Network, you now set up an Update session in order

to download the Check Sample product to the instrument(s). If you are on Local

Loading...

Loading...