•

Ensure chamber piston rods are in line

with the slack adjusters.

Wheel and Tire Inspection

Walk around the vehicle and visually inspect each

wheel and tire assembly.

IMPORTANT: Wheel covers decrease drag force

as a vehicle moves, thereby improving fuel effi-

ciency. If replacement of a wheel cover is nec-

essary, the replacement cover must meet or ex-

ceed the drag reduction performance of the

originally installed cover in order to maintain

compliance with greenhouse gas and full effi-

ciency regulations (GHG14).

1.

If the vehicle was originally equipped with wheel

covers, ensure all wheel covers are present. In-

spect wheel covers for damage or wear. Remove

wheel covers from rear drive wheels, if equipped,

prior to inspecting the tires and wheel compo-

nents.

NOTE: During wheel cover installation, ensure

the V-notch in the liner inner retaining ring is

centered on the valve stem. The inner and outer

retaining rings should be uniformly aligned to

each other and to the wheel rim. The outer re-

taining ring of the liner is equipped with two

canvas flaps. When installing the face cover,

make sure the cover retaining ring is inserted

between the two canvas flaps on the liner outer

retaining ring so that the Velcro strips line up

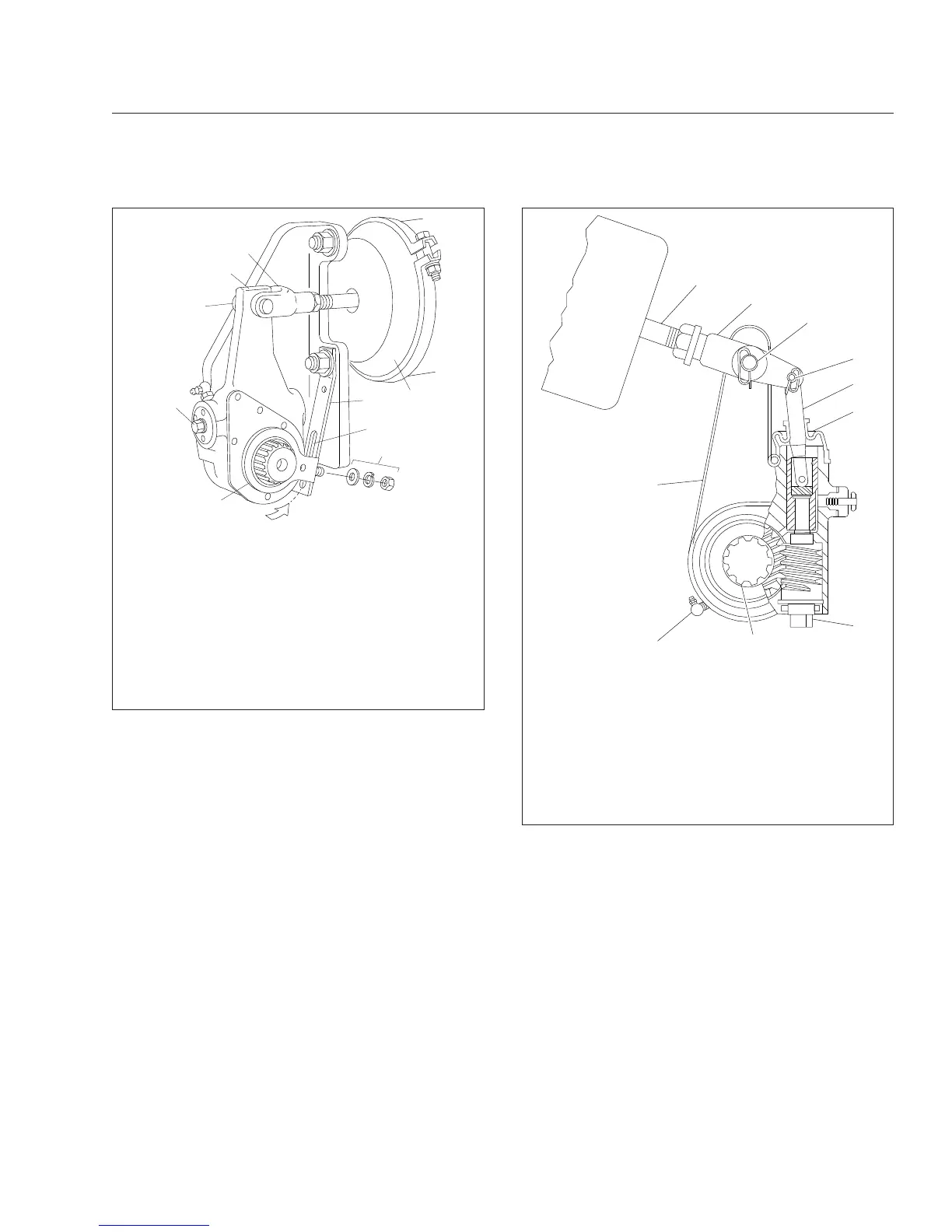

10/11/2005 f421397

1

2

3

4

5

6

7

8

9

A

A. Rotate the control arm toward the brake chamber

until you can feel it contacting the internal stop.

1. Clevis

2. Slack Adjuster

3. Clevis Pin

4. Manual Adjusting Nut

5. Control Arm

6. Control-Arm Washers and Nut

7. Anchor Strap Slot

8. Anchor Strap

9. Brake Chamber

Fig. 21.2, Haldex Automatic Slack Adjuster

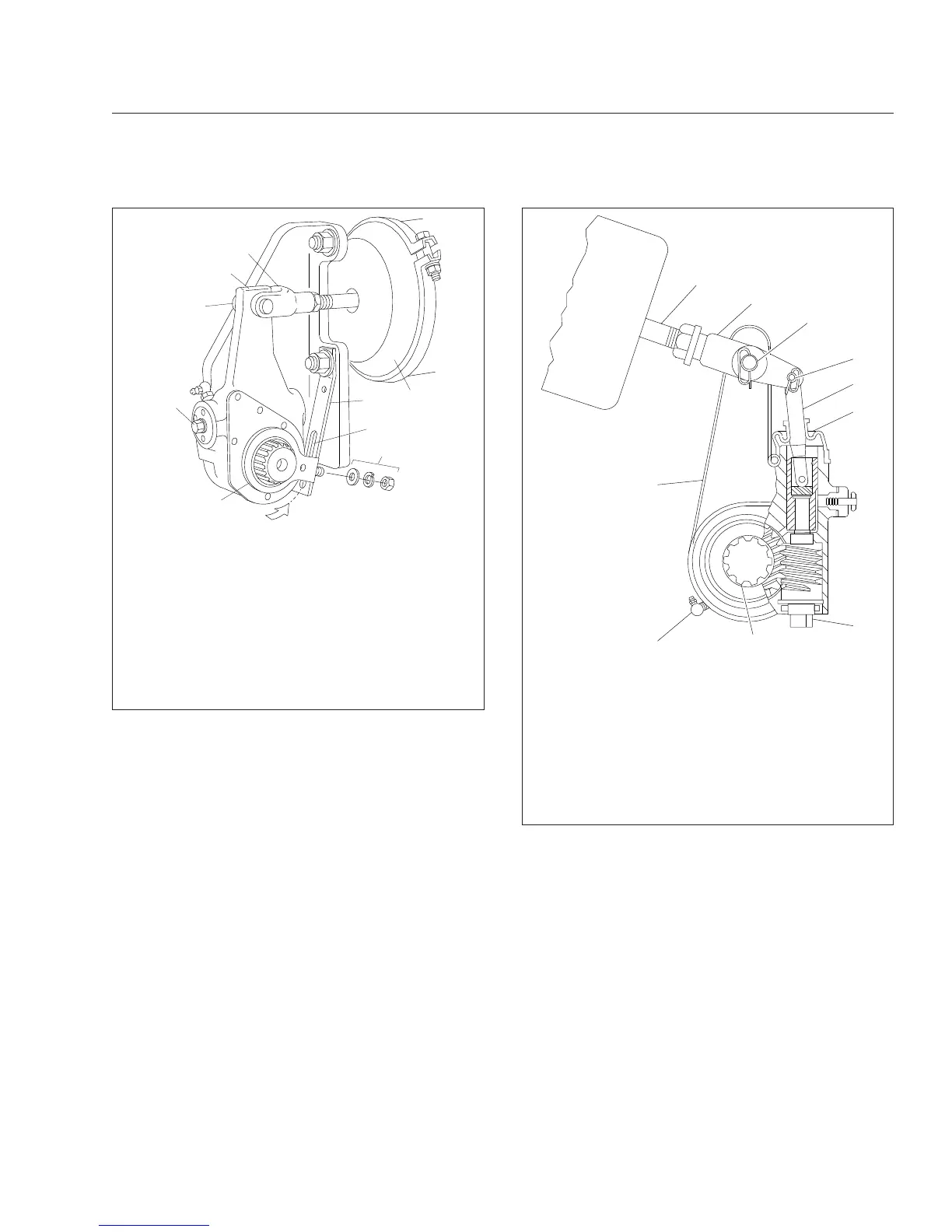

01/31/2011 f422530

1

2

3

4

5

6

7

8

9

10

1. Grease Fitting (if equipped)

2. Slack Adjuster Housing

3. Brake Chamber Pushrod

4. Clevis

5. Clevis Pin (large)

6. Clevis Pin (small)

7. Actuator Rod

8. Boot

9. Manual Adjusting Nut

10. Camshaft Splines

Fig. 21.3, Meritor Automatic Slack Adjuster

Pre- and Post-Trip Inspections and Maintenance

21.2

Loading...

Loading...