4.3

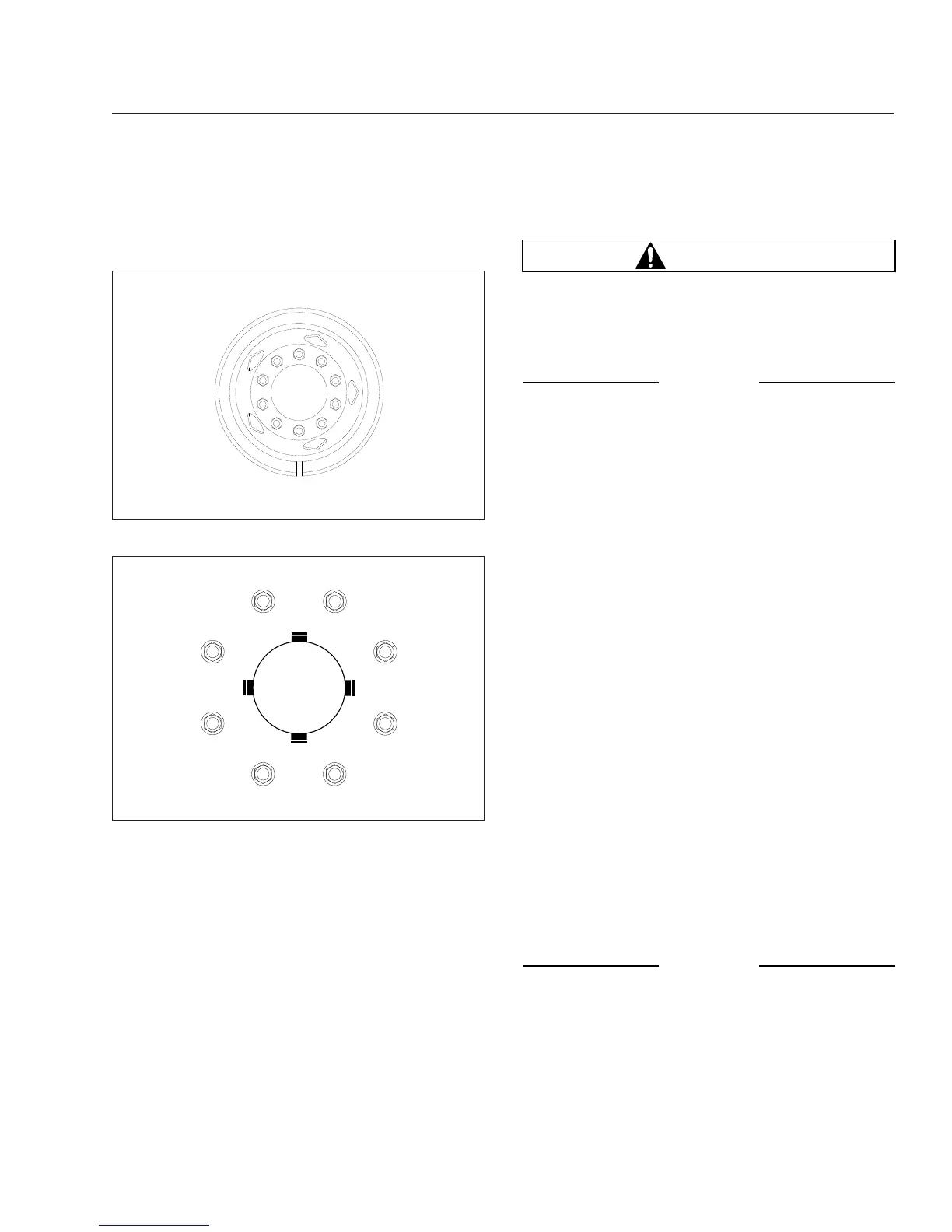

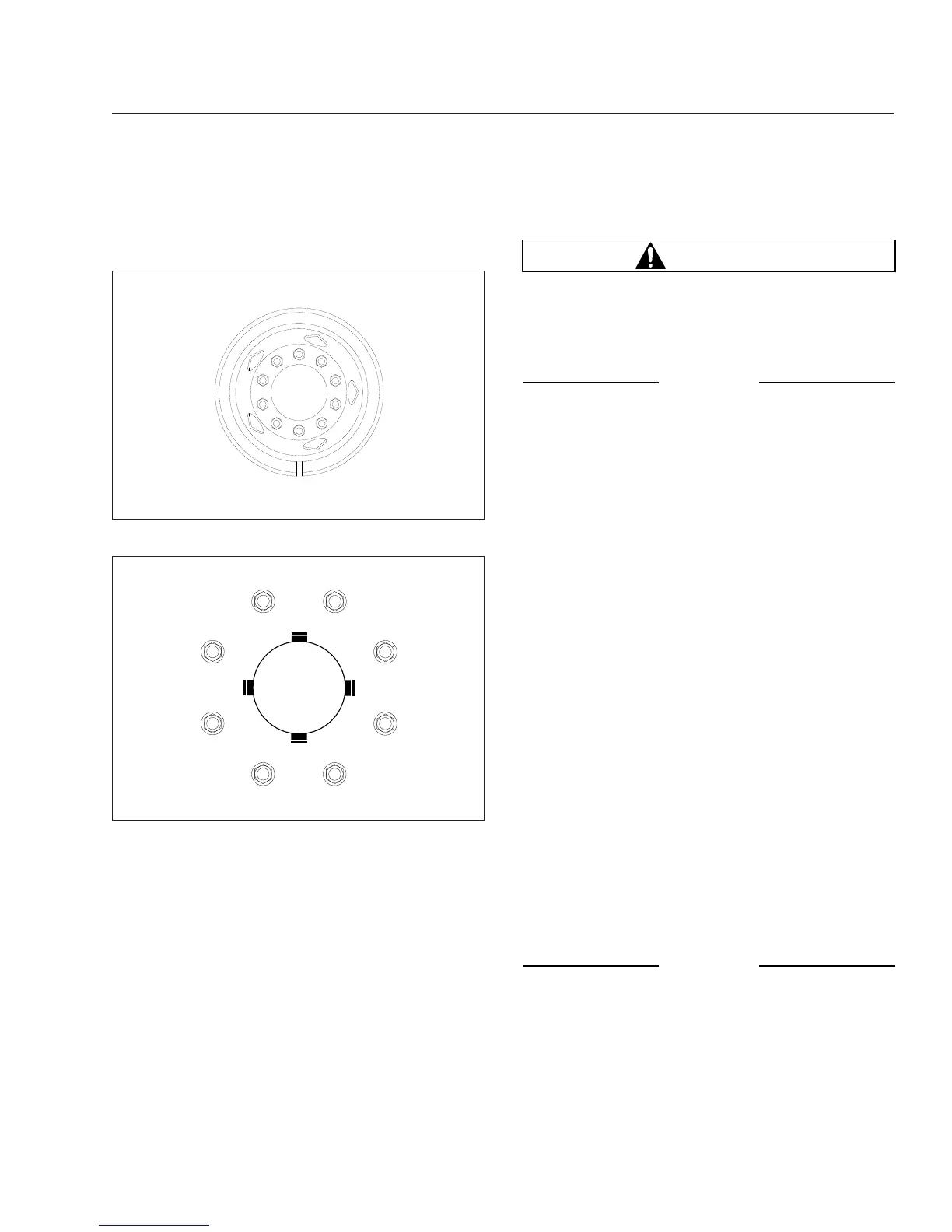

Make sure all wheel nuts are tightened. If

tightening is necessary, use the tightening

pattern in

Fig. 21.4 or Fig. 21.5.

5.

Inspect the outboard side of all wheel hubs and

the hub oil seal area on the inboard side of each

wheel for signs of oil leakage. If any oil is found

on wheel and tire or brake components, remove

the vehicle from service until the leak has been

fixed.

If needed, fill the hubs to the level indicated on

the hub cap. See Group 35 of the 108SD and

114SD Maintenance Manual for recommended

lubricants.

6.

Check that mud flaps are undamaged and hang

10 inches (25.4 cm) or less from the ground.

Saddle Tank Areas Inspection

WARNING

When draining the air reservoir, do not look into

the air jets or direct them toward anyone. Dirt or

sludge particles may be in the airstream and

could cause injury.

NOTICE

If the water drained from the air reservoirs is

cloudy or oily, it may indicate a problem with the

compressor. If oil is allowed to contaminate the

air dryer, it will not remove the water from the air

brake system, which could adversely affect brak-

ing.

1.

Drain the brake system air reservoirs (reservoirs

without automatic drain valves only).

2.

Ensure fuel tanks are secured to their mounting

brackets and that the mounting brackets are se-

cured to the frame.

3.

Inspect visible frame rails for missing bolts, shiny

areas, or rust streaks. Check all visible cross-

members for damage or signs of looseness.

4.

Inspect visible components of the exhaust sys-

tem to ensure connections are tight.

Inspect upstream of the aftertreatment device

(ATD) for cracking or signs of leaks, such as soot

trails. Inspect downstream of the ATD for signs of

exhaust leaks, such as blistering or warping of

nearby components.

Engine Compartment Inspection

1.

Check the ground underneath the engine for fuel,

oil, or coolant leaks.

2.

Inspect the air intake system for leaks or dam-

age.

NOTICE

Failure to maintain a sealed air intake system

could allow the entry of dirt and contaminants

into the engine. This could adversely affect en-

gine performance and result in engine damage.

1

2

3

45

6

7

8

9

10

f400081a

08/23/93

Fig. 21.4, Tightening Pattern, 10-Hole Wheels

f400052a

1

2

3

4

5

6

7

8

03/08/2012

Fig. 21.5, Tightening Pattern, 8-Hole Wheels

Pre- and Post-Trip Inspections and Maintenance

21.4

Loading...

Loading...