RWB II PLUS MICROPROCESSOR CONTROL

OPERATION

S70-200 OM

Page 13

COMMUNICATIONS TROUBLESHOOTING

Troubleshooting the communications:

Go to the FIXED SETPOINTS PAGE by using the “CHANGE”

key and the “ * ” key. The display will appear as:

FIXED SETPOINTS DISPLAY *

FIXED SETPOINTS: HIGH STAGE PRELUBE

COMM ACTIVITY—[ ] OIL PUMP PGM/A

Hi Disch Cut----[212F]

Hi Disch Alarm--[194F] Liq Inj Con 113F

Hi Oil Temp Cut-[167F] Filter------[25]

Hi Oil Temp Alarm[158F]Oil Heater[113F]

Lo Oil Temp Cut--[49F] Lo Oil Cut-[030]

Lo Oil Temp Alarm[58F] Lo Oil Alrm[025]

If the microprocessor is receiving information in the com-

munications port from the other compressor, a “2” will flash

between the brackets. During normal operation a “2” will flash

every 5 seconds.

At the same time information is display on the lower right

hand corner of the Auto Cycle display concerning the lead-

lag information:

AUTO CYCLE DISPLAY *

AUTO CYCLE Tue 04-10-90 08:44:57

DISPLAY: Press F1 To Exit

Suction Pressure--------[06.5 g ]

Comp Start - [99.0 g } Timer—[00 min]

Comp Stop— [29.0 hg] Timer—[00 min]

Min SV———[50%] Lead—[YES]

Active———[No ] 0111 111

This information is either “0” or “1” and represents what is

being sent from the other compressor. Consult Frick Com-

pany if additional information is required.

HOW THE MICROPROCESSOR WORKS

- SUMMARY -

The Frick microprocessor has 4 major components and a

variety of sensors. The major components are the SBC

(single board computer), two display screens, and the key-

board.

The SBC can be considered the brain of the microproces-

sor control console. The SBC contains the logic center which

provides the rules by which the microprocessor will oper-

ate, the integrated circuit chips which store the burned-in

memory of how the compressor unit is to behave, an analog

input to convert VDC from the various sensors into com-

puter binary language, and RAM (random access memory)

integrated circuit chips to store information which can be

readily changed by the microprocessor or, as in the case of

adjustable setpoints, by the operator. The SBC collects in-

formation, processes the information, and delivers instruc-

tions to the displays and to the output modules.

The SBC gathers information from several sources on the

compressor unit. Pressure transducers sense changes in

pressure and return a variable DC voltage of 1 to 5 VDC to

the SBC. The signals are converted into binary code which

the microprocessor understands. The microprocessor scans

the incoming data many times per second and compares

the information it receives with the instructions programmed

in the PROM chips, information stored in the RAM chips,

and instructions it has received from the console keyboard.

As operating conditions change, the microprocessor also

forwards the information it is receiving to the display screen.

When an operating condition or conditions develop which

the microprocessor program identifies as requiring a spe-

cific action, the microprocessor generates an instruction

which is forwarded to the output modules. The instruction

triggers a solid state output device capable of handling con-

trol voltage and the instruction is executed. In some cases,

such as load and unload instructions, the computer displays

the instruction on the Operating display with an L (load) or U

(unload) symbol at the same time as the appropriate output

is energized.

If the microprocessor receives information that indicates an

abnormal operating condition has been reached or is

present, it will generate one or more of the following instruc-

tions:

1. If a subsystem on the compressor unit, such as the oil

heater(s) or liquid injection, can correct the problem, the

microprocessor will energize or deenergize this system.

2. If a prealarm setpoint has been reached the micro-

processor will trigger the prealarm and display this informa-

tion on the Operating display and the Annunciator display.

3. If a cutout setpoint has been reached, the microproces-

sor will shut down the compressor. The microprocessor will

indicate CUTOUT on the Operating display and the infor-

mation present on the Operating display at the moment of

cutout will be stored and can be retrieved by rotating dis-

plays to the Freeze display. Additional information will be

available through the Annunciator and Shutdown Record

displays.

* Display for illustrative purposes only.

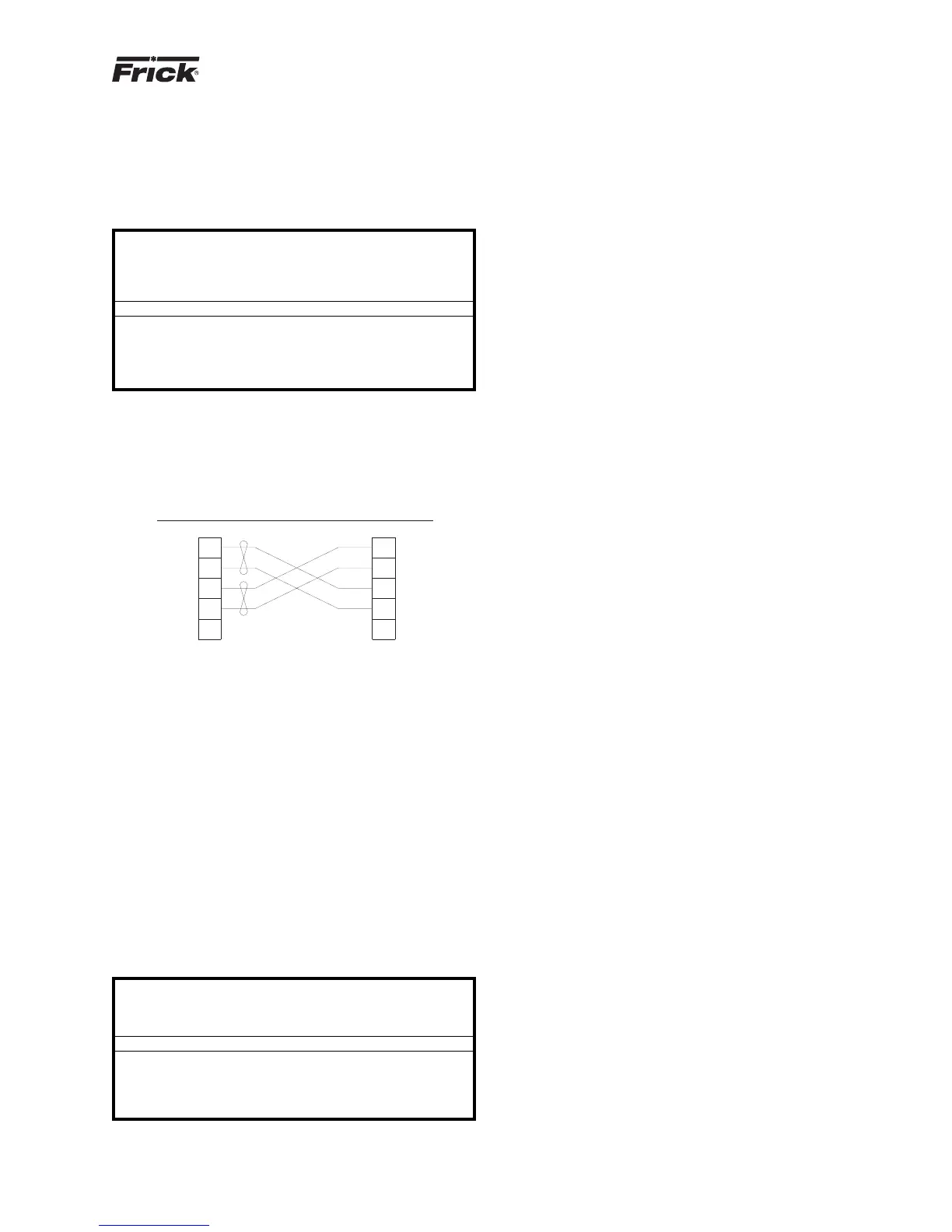

ARE ON THE SAME SKID

WIRED AT FRICK IF BOTH UNITS

DE-9P DE-9P

ON BOTH CONNECTORS

JUMPER PIN 1 TO 6 AND 2 TO 7

SBCSBC

WIRING FOR LEAD-LAG SEQUENCING

WITH DBCH-9 HOOD (2 THUS)

CONNECTORS-#DE-9P MALE

FROM ALL OTHER WIRING

RS 422 WIRING SHALL BE SEPARATE

COLOR CODING SHOWN IS BELDEN #8777

USE BELDEN #8777 OR EQUAL (3 TWISTED PAIRS)

BLK

RED

BLK

GRN

4

5

8

9

33

9

8

5

4

+RX +RX

+TX +TX

-RX -RX

-TX -TX

COM COM

UNIT "B"

PORT 2

RS422

UNIT "A"

PORT 2

RS422

OPTIONAL

NOTE: WHEN USING THE RS422 PORTS FOR LEAD-LAG, THEY

CANNOT BE USED FOR ANY OTHER COMMUNICATIONS.

Loading...

Loading...