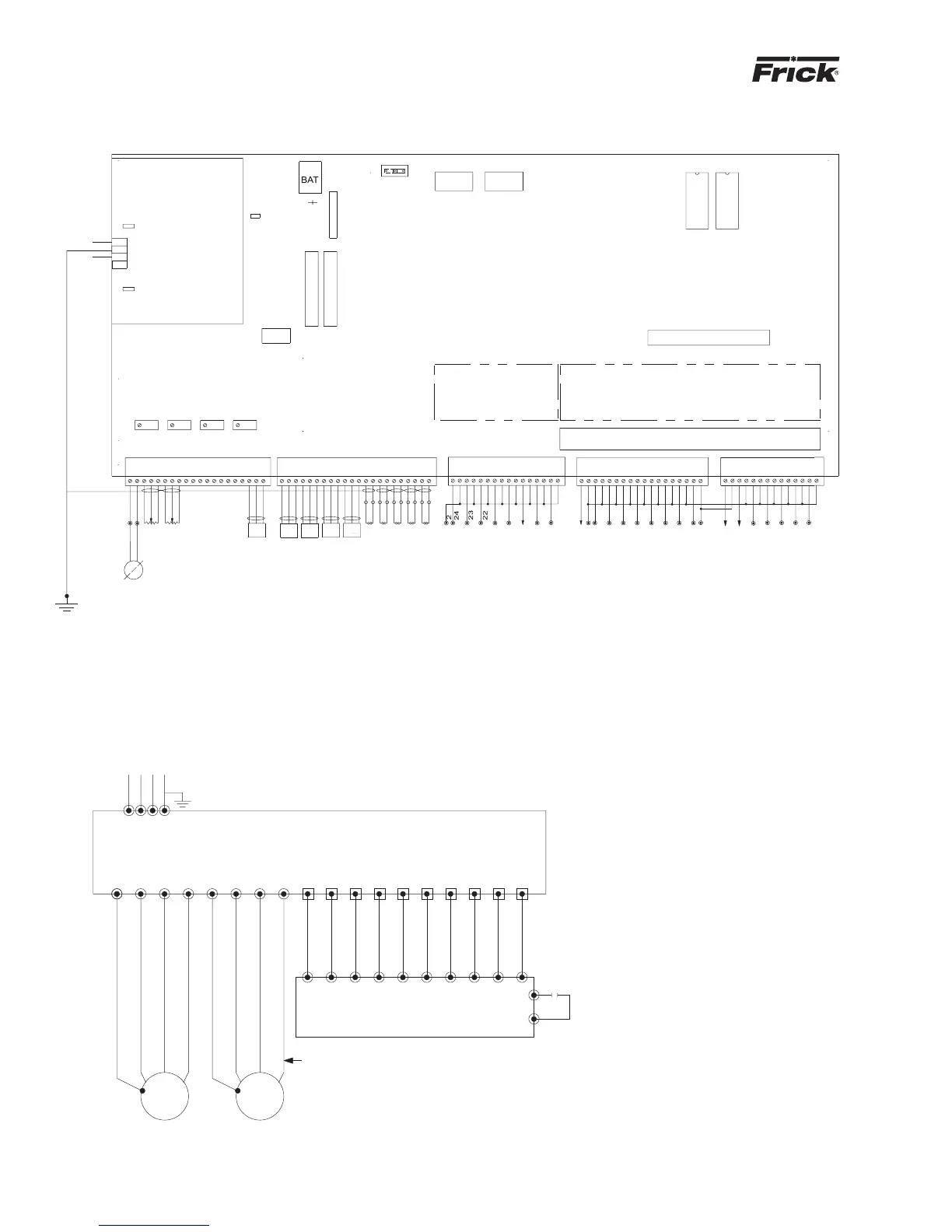

RWB II PLUS MICROPROCESSOR CONTROL

MAINTENANCE

S70-200 OM

Page 26

P2

18

6

GROUND

LUG

RED

3

RED

4

1

3

3

1

RED

BLK

WHT

RED

2

BLK

WHT

2

R

AMPS

R

MOTOR

VALVE

B

R

W

P5

B

W

R

SLIDE

STOP

SLIDE

SLIDE STOP

SLIDE STOP

SPAN

ZERO

TEMP

P4

WHT

SUCT

-

+

S

+

BLK

WHT

RED

RED

PRES

SPARE

SPARE

ECON

PRES

SPARE

--

SS

+ +

-

S

BLK

WHT

RED

BLK

BLK

WHT

RED

+

-

S

W

BLK

WHT

RED

BLK

BLK

W

B

B

FILTER

PRES

DISCH

PRES

PRES

SPARE

PRES

OIL

TEMP

SEP

ANALOG

EXPANSION

SLIDE VALVE

SLIDE VALVE

SPAN

ZERO

1

1

1

DIGITAL INPUTS

6

BLK

B

BLK

W

B

W

BLK

B

W

TEMP

DISCH

TEMP

OIL

SUCT

TEMP

1

2

3

1

2

P3

4

3

5

30

28

20

21

29

38

13

4

5

6

8

7

9

10

11

12

1

8

7

14

15

16

17

MODULES

DIGITAL INPUT

230

NEU

GND

115

2

5

BATTERY

P12

P15

P10

P6

P11

P9

OFF

ON

PORT

2

3

PORT

1

3

DIGITAL OUTPUTS

14

16

17

15

13

12

11

DIGITAL OUTPUTS

5

4

3

2

22

21

20

19

25

24

23

7

6

8

29

28

27

26

32

31

30

35

9

10

5

7

34

33

37

11

10

9

34

33

36

35

P1

12

13

14

41

40

39

38

44

43

42

DIG I/O EXPANSION

MODULES

DIGITAL OUTPUT

32

31

15

16

48

47

46

45

U5

U4

CHANNEL 16

CHANNEL 15

CHANNEL 14

CHANNEL 13

CHANNEL 12

CHANNEL 11

CHANNEL 10

CHANNEL 9

CHANNEL 8

CHANNEL 7

CHANNEL 6

CHANNEL 5

CHANNEL 4

CHANNEL 3

CHANNEL 2

CHANNEL 1

NEUTRAL

OIL LEVEL SWITCH

REMOTE RUN

REMOTE LOAD

REMOTE UNLOAD

COMPRESSOR AUX

COMPRESSOR START RELAY

OIL PUMP SEL SW

AUX 2

POWER

POWER

DATA BIT 0

DATA BIT 1

DATA BIT 2

DATA BIT 3

OIL HEATER RELAY

OIL PUMP SEL SW

SPARE ON ALL UNITS EXCEPT 496 & 676

WHERE USED AS INLET BEARING FEED

SLIDE VALVE LOAD

SLIDE VALVE UNLOAD

SLIDE STOP INCREASE

SLIDE STOP DECREASE

LIQUID INJECTION

HI VI LIQ INJ

ECONOMIZER

ALARM

AUX 1

TE-5

TE-4

TE-3

TE-2

TE-1

MOTOR

AMPS

SLIDE STOP

POSITION 3

SLIDE VALVE

POSITION 1

RWBP60

FRICK REV D

RWBII PLUS

---- ----

-----

POWER

SUPPLY

++++ ++++

+++++

SSSS SSSS

FUSES FU1 - FU6

F1

P13

F2

SBC WIRING DIAGRAM

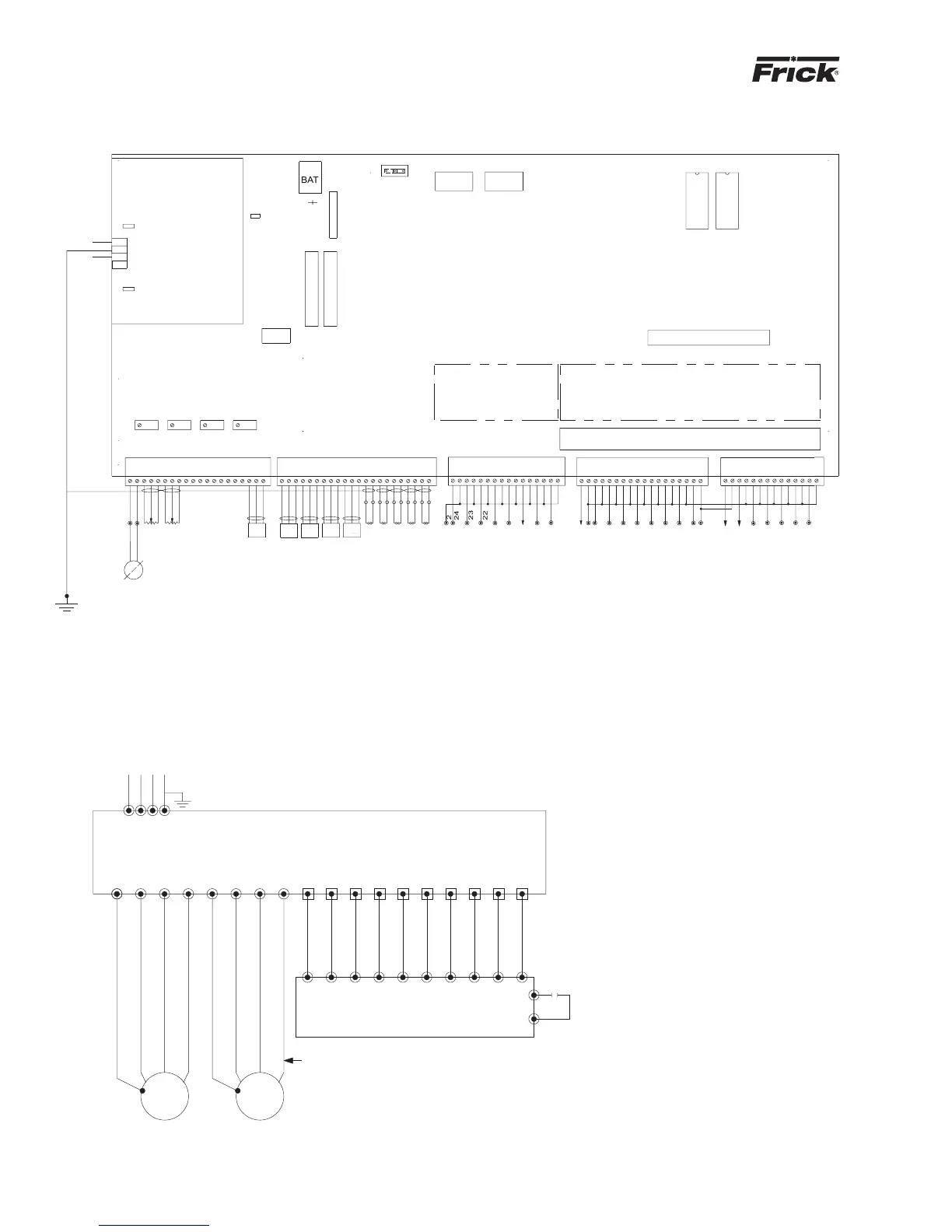

POINT-TO-POINT FIELD WIRING DIAGRAM

RWBII PLUS

RXB PLUS

RDB PLUS

RXF

GND

20

18

19

4

3

5

8

1

2

T3

T2

T1

GNDGND

T1

T2

T3

3 PHASE LINE

GND

1

2

3

4

5

8

18

19

20

GND

FRICK MICRO ENCLOSURE

OIL

PUMP

MOTOR

3 PHASE SUPPLY TO MOTOR

MOTOR

COMPR

T3

T2

T1

GND

T3

T2

T1

GND

FRICK SUPPLIED

1. REFER TO MOTOR NAMEPLATE

FOR CORRECT MOTOR CONNECTION.

2. SEPARATE CONDUIT RUNS FOR

CONTROL VOLTAGE WIRING AND MOTOR

CONNECTION WIRING.

3. CONDUIT GROUNDS ARE NOT ACCEPTABLE.

4. ALL WIRING MUST BE PER LATEST EDITION

OF THE NEC AND LOCAL CODES.

5. ALL CONTROL VOLTAGE WIRING TO

14 AWG STRANDED COPPER WIRE.

T1

T2

T3

GND

CONSULT STARTER AND MOTOR WIRING DIAGRAMS

FOR EXACT WIRING CONFIGURATION.

HI-LEVEL CUTOUT AND/OR OTHER FIELD SAFETY

CUTOUTS AS REQUIRED.

NOTES:

COMBINATION STARTER PACKAGE

Loading...

Loading...