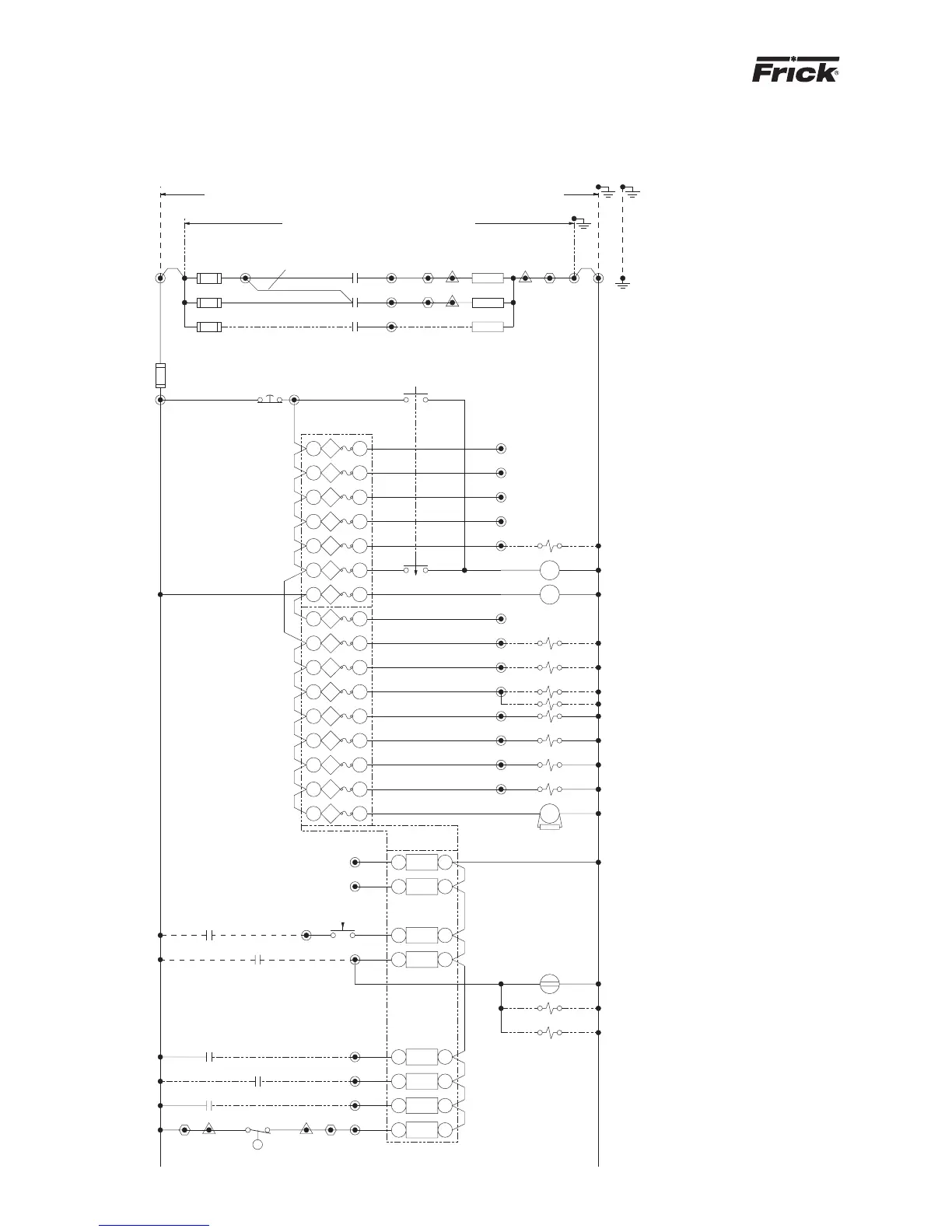

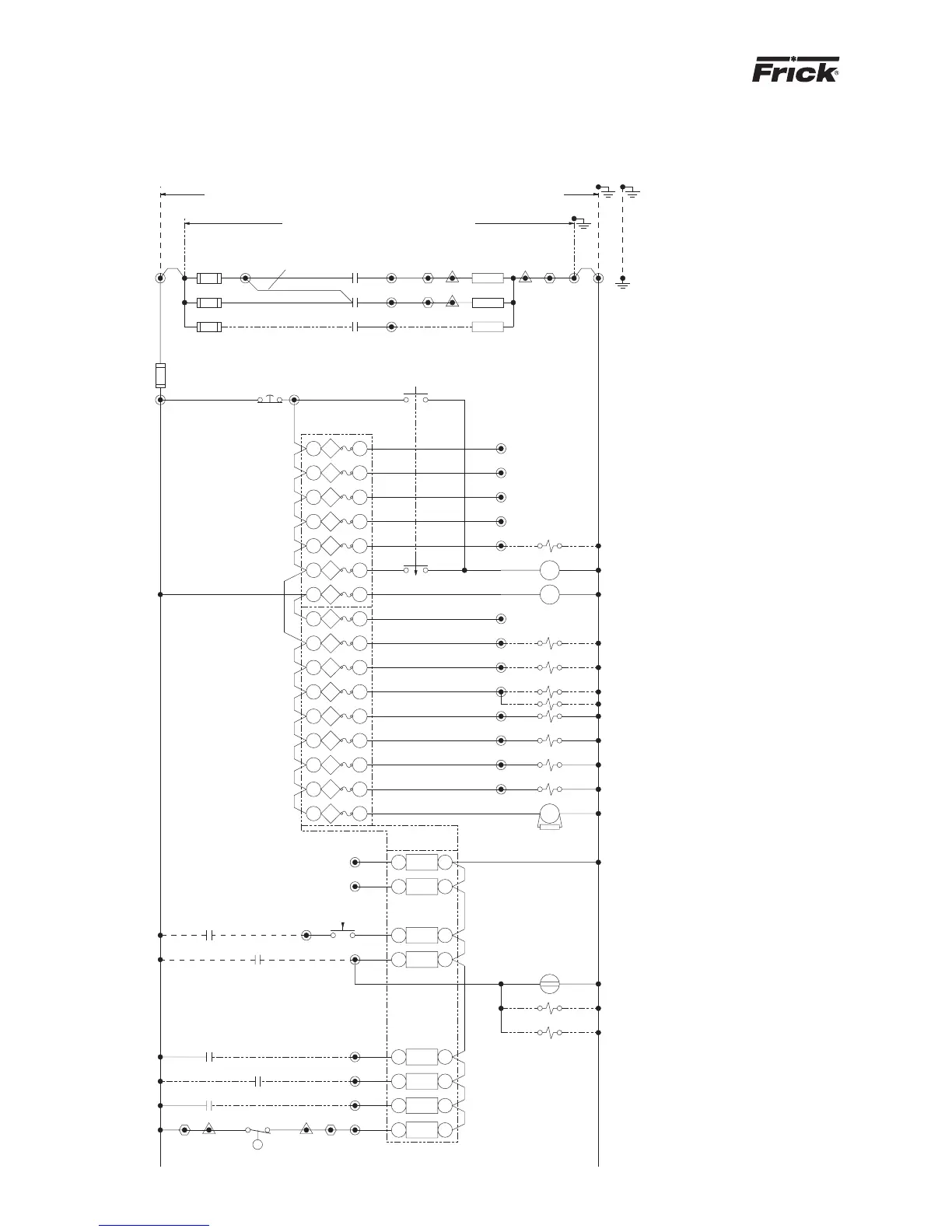

RWB II PLUS MICROPROCESSOR CONTROL

MAINTENANCE

S70-200 OM

Page 28

30 7 29

HI VI LIQ INJ (IF REQ'D)

19

REMOTE START/RUN/STOP

REMOTE LOAD

38

39

5

37

36

35

34

33

REMOTE UNLOAD

22

(SAFE)

1LSL

24

23

21

COMPR. AUX

31

32

30

OIL PUMP AUX

29

28

27

26

20

FROM LN.15

(00X)

19 28

B

30

29

25

24

23

22

21

20

FU1

18 1 17

FU2

FU3

20 2

22 3

19

21

FU5

FU4

24 4

26 5

23

25

FU6

28 6 27

LIQUID INJECTION

(FULL & CYCLING OIL PUMP)

ONLY USED WITH VERT. SEP'RS.)

MAIN OIL INJ. FEED

FULL LUBE OIL PUMP)

(NOT REQUIRED WITH

OIL LEVEL

REMOTE START/RUN/STOP

REMOTE LOAD

REMOTE UNLOAD

(ONLY ON BOOSTERS WITH LIQ INJ)

PRESSURE REGULATOR

21

42

1

3

6

8

3

4

5

7

2

FOR SECOND LIQ INJ (IF REQ'D)

COMPR. RUN TIME METER

(IFREQ'D)40

COMPRESSOR AUX

OIL PUMP AUX

AUX 1 (SEE NOTE B)

AUX 2 (SEE NOTE B)

COMPR START/RUN

SLIDE VALVE LOAD

SLIDE VALVE UNLOAD

SLIDE STOP INCREASE

SLIDE STOP DECREASE

LIQUID INJECTION (IF REQ'D)

10 5

12 6

9

11

14 7

16 8

13

15

17

38

16

15

14

13

12

NOTE C

SEE

CR

2

60

A SEPARATE 115 OR 230 VAC SOURCE TO 1A & 2A

CUSTOMER SUPPLIED 115 OR 230 VAC CONTROL TRANSFORMER POWER SOURCE IS REQUIRED

REMOVEJUMPERS1TO1A&2TO2A&CONNECT

IF SEPARATE FEED OR VOLTAGE FOR HEATER CIRCUIT IS DESIRED,

ALL POWER SOURCES SHALL BE GROUNDED ON ONE SIDE

-ISOLATED AND SEPARATED FROM OTHER INDUCTIVE LOADS SUCH AS LIGHTING CIRCUITS

-OR FROM FRICK SUPPLIED OR SPECIFIED STARTER, USE MINIMUM #12 AWG FOR FEED

RED

25B

12

18

17

16

15

14

13

FU10

FU7

FU8

32 8 31

FU9

34 9

36 10

33

35

FU11

38 11

40 12

37

39

FU12

FU13

42 13 41

11

10

09

2FU

10

07

08

5

06

FU14

FU15

44 14

46 15

43

45

SBC TERMINALS

FOR DIGITAL I/O

FU16

48 16 47

EMERGENCY

STOP

6

FOR 1 KW, 115 V HTR'S, MOVE

WIRE TO 1A FU & NUMBER 25A

ADD1BFUFOR3rdHTR

ADD1AFUFOR115V-1KWHTR'S

05

04

#14

03

02

1

#12

1A FU

15

1B FU

15

15

1FU

1A

HOT

01

HOT

25A

25

1CR

1CR

1CR

27A

ALL HEATER WIRING

3,4,(5)

ALARM (PRE & CUTOUT)

RELAY&/ORLAMPOPTIONAL

EXCEPT WHERE NOTED

WIRING TO BE WHITE

ALL NEUTRAL (EXP: 2 & 2A)

TO BE #14 AWG

ON RWB'S 316-676 IF REQ'D

BALANCE PISTON

RELAY&/ORLAMPOPTIONAL

ALARM (PRE & CUTOUT)

OIL PUMP START/RUN

SPARE ON ALL OTHERS

DATA CODE BIT 0

PROGRAMMABLE CONTROL

DATA CODE BIT 1

PROGRAMMABLE CONTROL

DATA CODE BIT 2

PROGRAMMABLE CONTROL

DATA CODE BIT 3

PROGRAMMABLE CONTROL

ECONOMIZER (IF REQ'D)

OIL HEATER

33

10

11

99

(OOX)

TO LN.30

35

B

39

7

34

CR

1

CR

3

63

32

31

AUTO

OIL PUMP

(XOO)

HAND

A

OFF

39

3rd HEATER WHEN REQUIRED

EARTH BUSBAR AT

POWER SOURCE

GROUND BAR IN MICRO

1 KW HTR'S OPTIONAL

.5 KW HTR'S

SEPARATOR OIL HEATERS

27

26

HEATER

HEATER

HEATER

2A 2

#12

NEUTRAL

NEUTRAL

TIE NEUTRAL TO GROUND

AT SOURCE

ALL NEUTRALS ENTERING

THIS ENCLOSURE SHALL

BE TIED TOGETHER AT

SOURCE, NOT IN THIS

ENCLOSURE

MICROPANEL ASSEMBLY WIRING DIAGRAM

Loading...

Loading...