7

ENGLISH

COMMISSIONING - GENERAL DETAILS

Warning! EXTERNAL INTERFERENCE CAUSED BY TIG

WELDING USING HIGH FREQUENCY (HF)

The high frequency used for contact-free ignition with AC/DC TIG

welding, can interfere with the operation of insufficiently shielded

computer equipment, EDP centres, industrial robots, computer-

controlled processing equipment and measuring stations, even

causing complete system breakdown. Also, TIG welding in resi-

dential areas may interfere with electronic telephone notworks

and with radio and TV reception.

ELECTRICAL WORK, CHANGING THE FUSES ON THE

MAINS SUPPLY PC BOARD, OR FITTING/CHANGING

THE POWER PLUG, MAY ONLY BE CARRIED OUT BY A

QUALIFIED ELECTRICIAN!

The Magic Wave 2000

Fuzzy

resp. Transtig 2000

may be

operated as standard on a mains voltage of 1x200V/220/230V

or 240V

(+/- 10% tolerance range)

.Thanks to its electronic pre-

control, the machine automatically adapts itself to the mains

voltage supplied to it. This voltage must be in the 175V - 265V

range

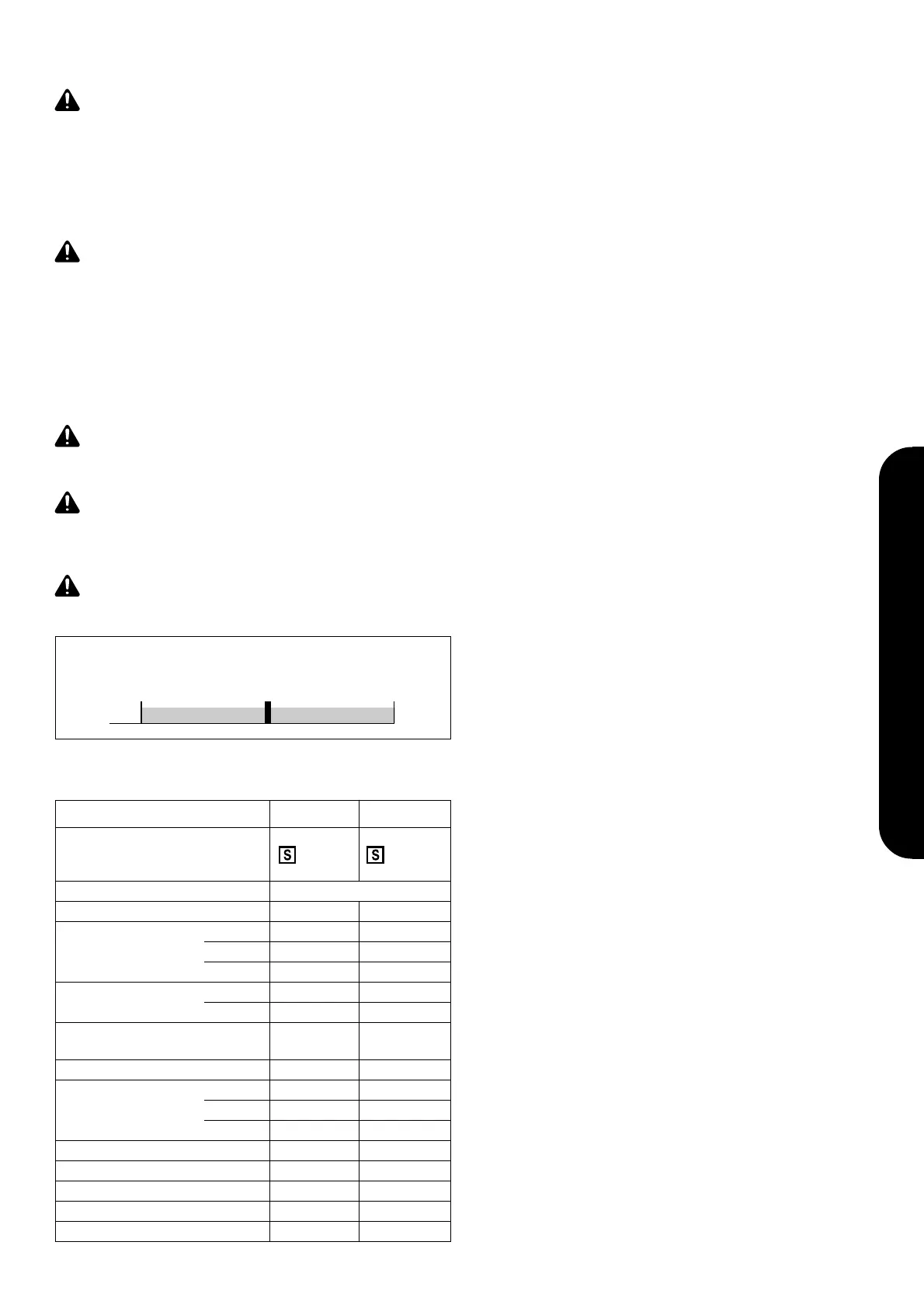

(Fig. 4)

.

ON MACHINES DESIGNED FOR USE WITH A SPECIAL

VOL-TAGE, THE TECHNICAL DATA ON THE MACHINE

RATING PLATE WILL APPLY.

THE MAINS PLUG USED MUST CORRESPOND EXACT-

LY TO THE MAINS VOLTAGE AND CURRENT RATING OF

THE WELDING MACHINE IN QUESTION, AS GIVEN IN

THE TECHNICAL DATA!

THE FUSE PROTECTION FOR THE MAINS LEAD SHOULD

BE SUITABLE FOR THE CURRENT CONSUMPTION OF

THE WELDING MACHINE!

175V

200V

220V

230V

240V 265V

Fig. 4 Tolerance ranges of the mains voltages 1x200V/220V/230V oder 240V

SETTING-UP INSTRUCTIONS

DEGREE OF PROTECTION: IP23

The machine is tested to IP23, meaning that it is protected against:

- penetration by solid bodies > diam. 12 mm

- spray up to an angle of 60° to the vertical

OPEN-AIR OPERATION

As indicated by its protection category IP23, the machine may be

set up and operated in the open air. However, the built-in electrical

parts must be protected from direct wetting (see protection cate-

gory IP23)

COOLING AIR AND DUST

Position the machine so that the cooling air can be drawn in freely

through the louvers, and then be expelled unhindered. The cool-

ing air passes through ventilating slits in the casing into the interior

of the machine, where it cools inactive components in the ven-

tilation channel before flowing out through the ventilation outlet.

The ventilation channel has an important protective function. The

following cooling cycle is automatically controlled by an electronic

thermostatic cut-out system. (Fig. 1)

Make sure that any metal dust caused by e. g. grinding work is not

sucked into the machine by the cooling fan.

STABILITY

The power source can be stood on a surface with an inclination of

up to 15°! At inclinations above 15° there is a risk of the power

source toppling over.

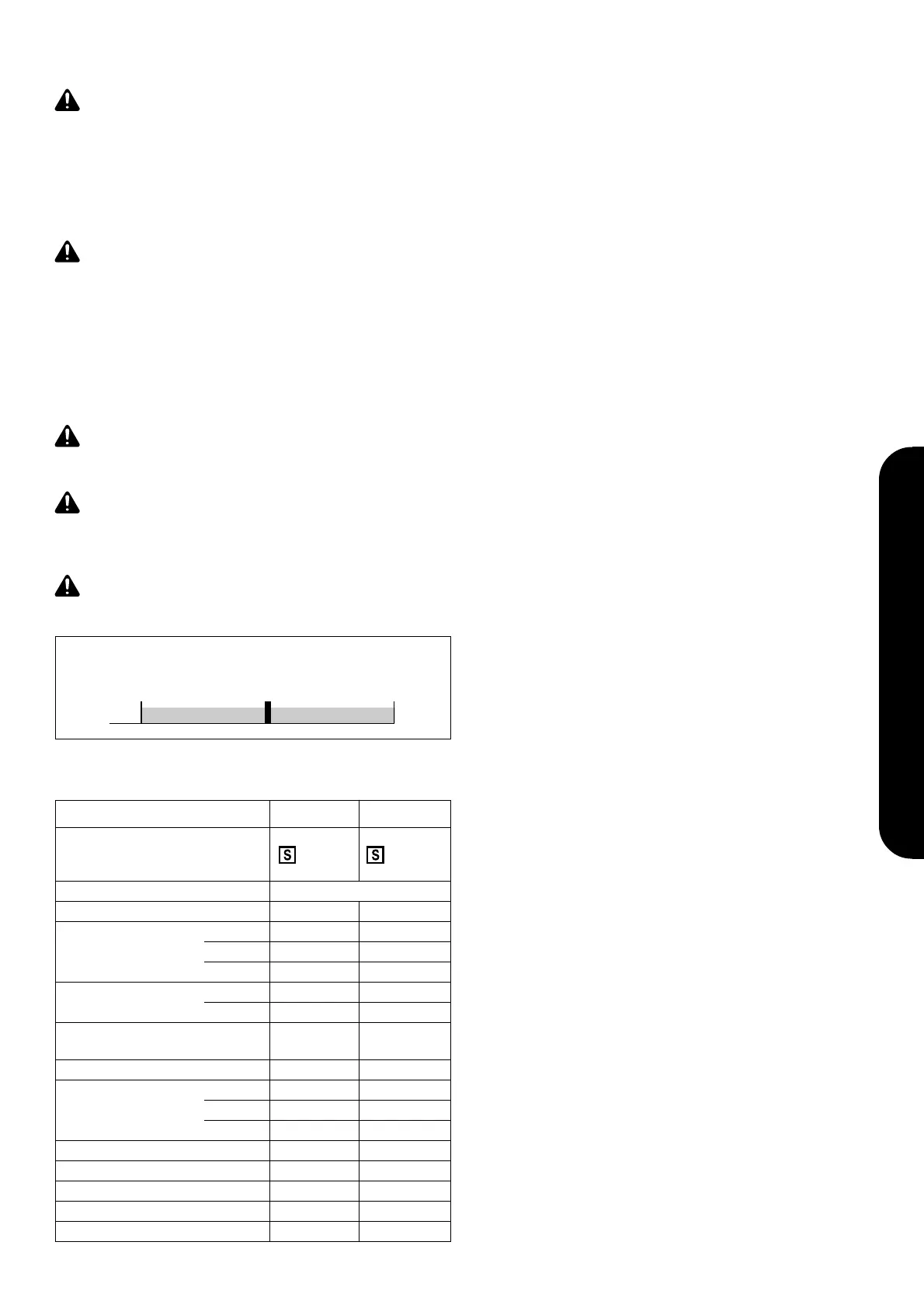

MW 2000 TT2000

Machine suitable for welding in

confined spaces under conditions

of increased electrical danger

Mains voltage +/-10% 1x200/220/230/240V 50-60Hz

Mains fusing 230 V 16 A slow blow 16 A slow blow

Apparent power at 100 % d.c. 2,4 kVA 2,2 kVA

60 % d.c. 3,3 kVA 3,1 kVA

35 % d.c. 5,0 kVA 4,8 kVA

Cos phi (150 A) 1 1

(200 A) 1 1

Welding current range TIG 3 - 200 A DC 3 - 200 A DC

5 - 200 A AC

Welding current range Electrode 3 - 180 A 3 - 180 A

Welding current at 35 % d.c. 200 A 200 A

(d.c.: 10min. at +40°C) 60 % d.c. 150 A 150 A

100 % d.c. 120 A 120 A

Operating voltage Electrode/Tig 0 - 35 V 0 - 35 V

Open-circuit voltage 45 V 45 V

Insulation category F F

Protection class IP 23 IP 23

Type of cooling AF AF

TECHNICAL DATA

Loading...

Loading...