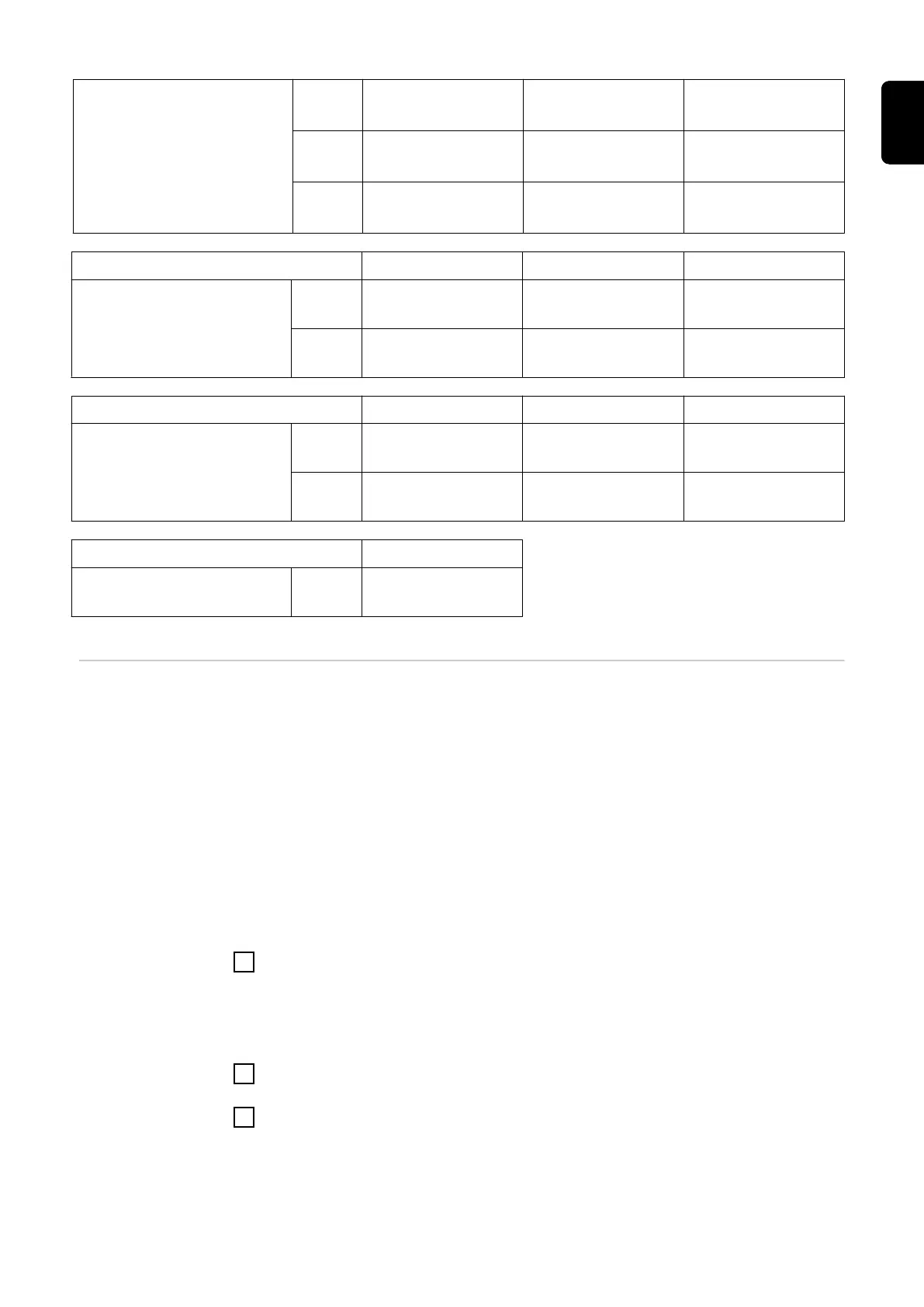

Copper (Cu)/aluminum

(Al)

208 V

A

C

AWG 10/AWG 10 AWG 10/AWG 8 AWG 8/AWG 6

220 V

A

C

AWG 10/AWG 10 AWG 10/AWG 8

240 V

A

C

AWG 12/AWG 10 AWG 10/AWG 10

10.0-3 480 12.5-3 480 15.0-3 480

Copper (Cu)/aluminum

(Al)

440 V

AC

AWG 14/AWG 12 AWG 14/AWG 12 AWG 14/AWG 12

480 V

AC

AWG 14/AWG 12 AWG 14/AWG 12 AWG 14/AWG 12

17.5-3 480 20.0-3 480 22.7-3 480

Copper (Cu)/aluminum

(Al)

440 V

AC

AWG 12/AWG 10 AWG 10/AWG 10 AWG 10/AWG 8

480 V

AC

AWG 14/AWG 12 AWG 12/AWG 10 AWG 10/AWG 10

24.0-3 480

Copper (Cu)/aluminum

(Al)

480 V

AC

AWG 10/AWG 10

Preparing Alu-

minum Cables

for Connection

The AC-side terminals are designed for connecting single-wire, round aluminum

cables. Due to the reaction of aluminum with air that creates a tough, non-con-

ductive oxide layer the following points must be considered when connecting alu-

minum cables:

-

Reduced rated currents for aluminum cables

-

The connection requirements listed below

Always follow the instructions of the cable manufacturer when using aluminum

cables.

Take into account local specifications when configuring cable cross sections.

Connection Requirements:

1

Carefully clean off the oxide layer of the stripped end of the cable, e.g., using

a knife

IMPORTANT! Do not use brushes, files, or sandpaper; aluminum particles may

get stuck and can transfer to other cables.

2

After removing the oxide layer of the cable end, rub in a neutral grease, e.g.,

acid-free and alkali-free Vaseline

3

Then immediately connect it to the terminal

IMPORTANT!Repeat the steps above whenever the cable is disconnected and

then reconnected.

29

EN-US

Loading...

Loading...