75

EN

Fronius-recommended procedures

Simultaneously

selecting the

“Job number“ or

“Program num-

ber“ signal and

the “Welding

start“ signal

NOTE!

Simultaneously selecting the “Job number“ signal or “Program number“ signal and

the “Welding start“ signal can affect the ignition and the welding data documenta-

tion.

Recommended

procedures for

job/program se-

lection without

changing the

characteristics

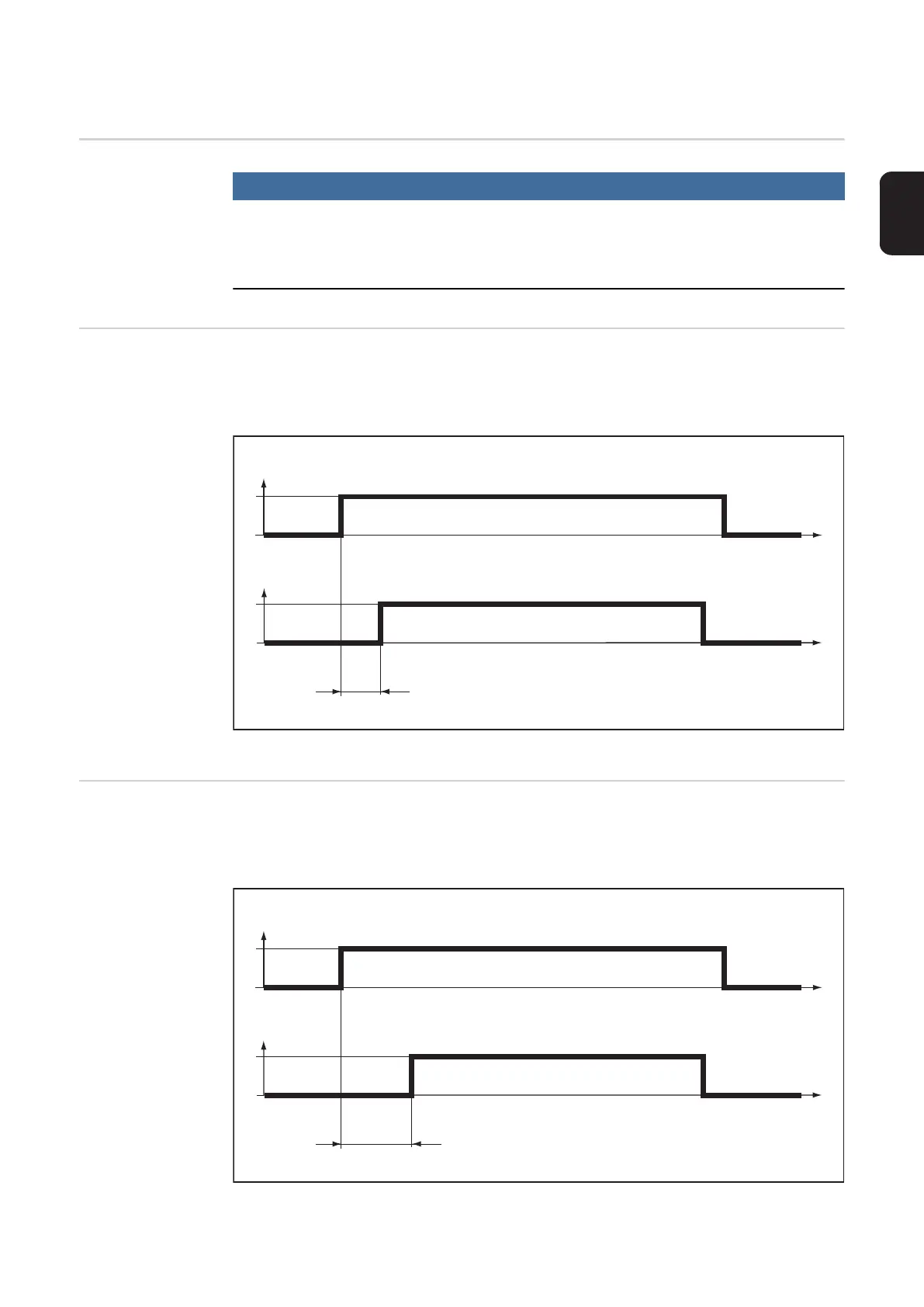

To select a job or program without changing the characteristics, Fronius recommends a

time gap of at least 0.1 s between the “Job number“ or “Program number“ signal (1) and

the “Welding start“ signal (2).

Selecting job/program without changing the characteristics

Recommended

procedures for

job/program se-

lection and

changing the

characteristic or

operating mode

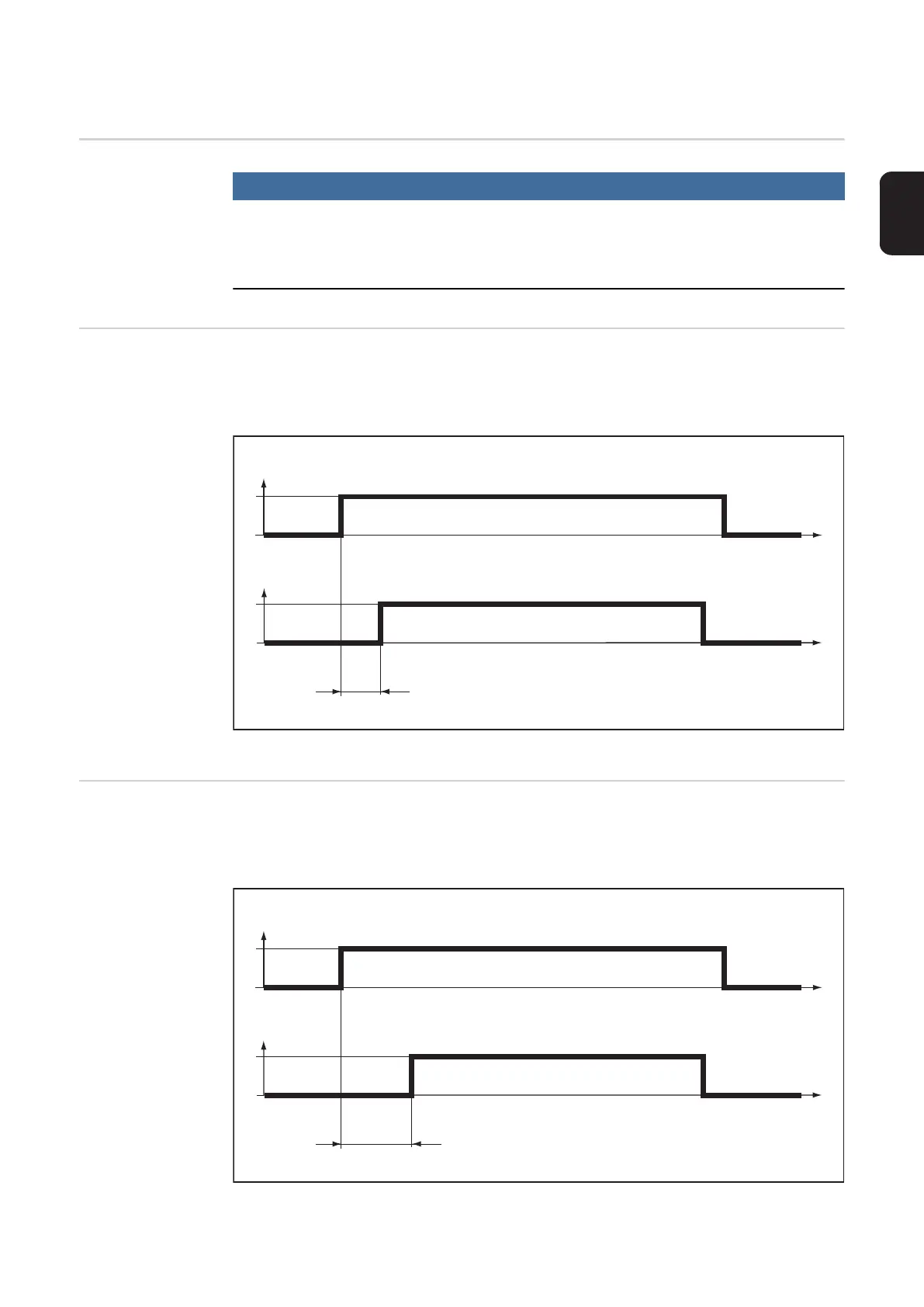

To select a job or program with a change to the characteristics or operating mode as well,

Fronius recommends a time gap of at least 0.3 - 0.8 s between the „Job number“ or „Pro-

gram number“ signal (1) and the „Welding start“ signal (2).

Selecting job/program and changing the characteristics or operating mode

min. 0,1 s

0

1

0

1

t (s)

t (s)

(1)

(2)

min. 0,3 - 0,8 s

0

1

0

1

t (s)

t (s)

(1)

(2)

Loading...

Loading...