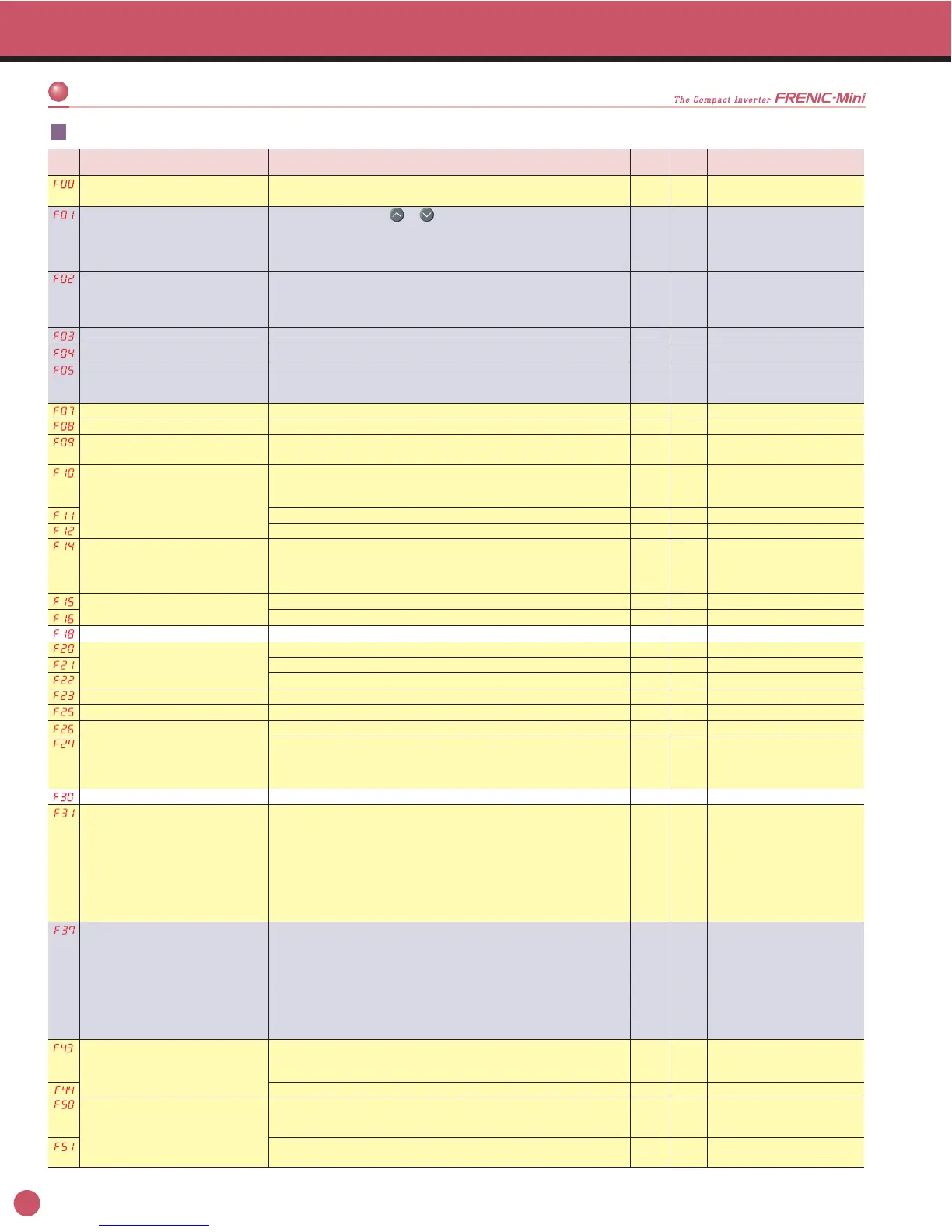

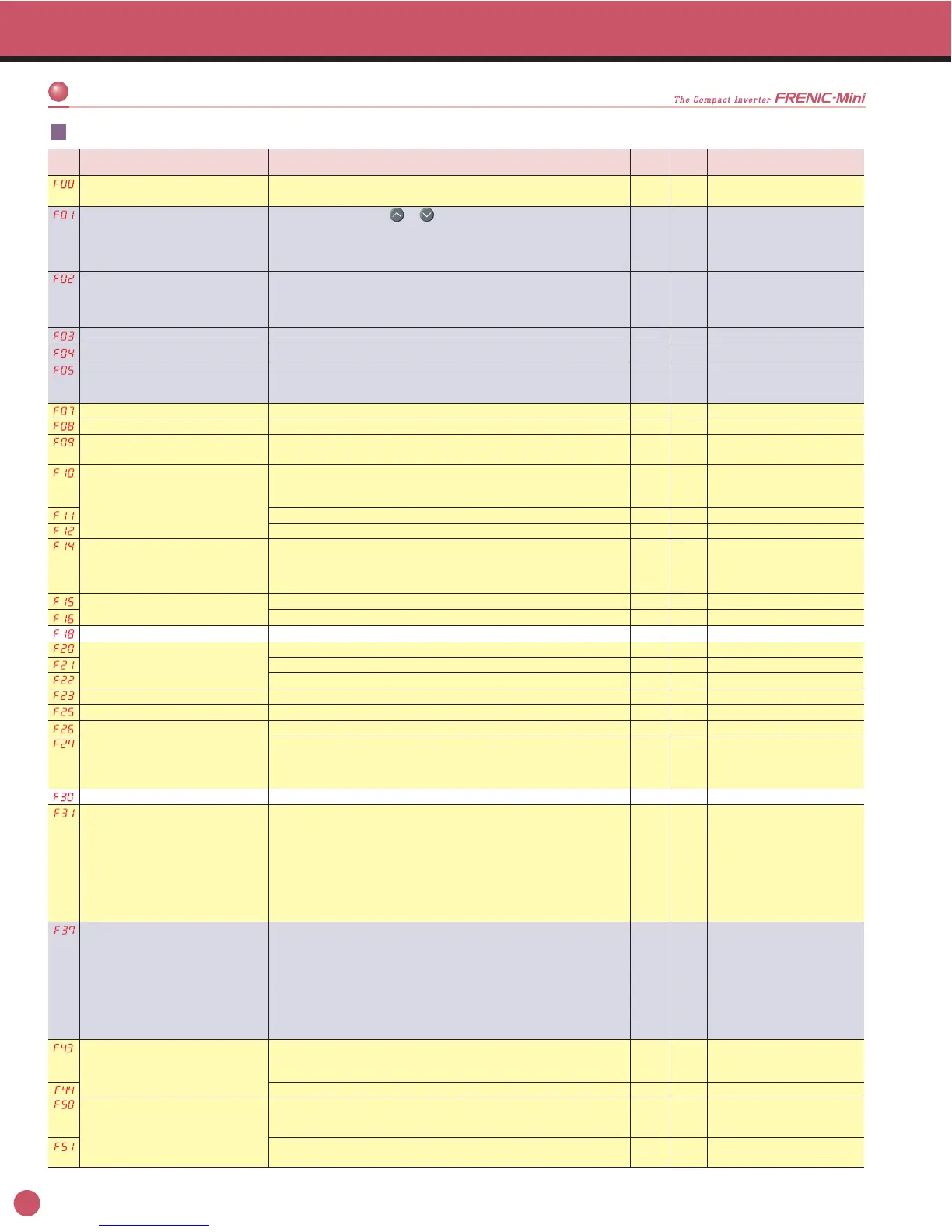

Function Settings

Function Settings

Func.

code

Name Data setting range

0 : Disable data protection

1 : Enable data protection

--

0

4

2

Data Protection

Factory settingMin. Unit

0 : Keypad operation ( or key)

1 : Analog voltage input (terminal 12) (0 to +10V DC)

2 : Analog current input (terminal C1) (+4 to +20mA DC)

3 :

Analog voltage input (terminals 12) and analog current input (terminal C1)

4 : Potentiometer on the keypad

0 : Keypad operation (FWD/REV change by external signal)

1 : External signal (Digital input)

2 : Keypad operation (FWD)

3 : Keypad operation (REV)

--

--

60.00.1 Hz

60.0

230

460

0.1 Hz

70.00.1 Hz

1V

Frequency Command 1

Running/Stopping and

Rotational Direction

25.0 to 400.0HzMaximum Frequency

25.0 to 400.0HzBase Frequency

6.000.01 s

0.00 to 3600s : *0.00 means acceleration time ignored (External soft start/stop)

Acceleration Time 1

0V : Voltage in proportion to power supply voltage

80 to 240V : AVR active (115, 230V series)

160 to 500V : AVR active (460V series)

Rated Voltage (at base frequency)

6.000.01 s

Rated current of Fuji's standard motor

0.01 A

1

--

0

--

0

--

Fuji's standard torque boost0.1 %

0.00 to 3600s : *0.00 means deceleration time ignored (External soft start/stop)

Deceleration Time 1

0.0 to 20.0% (percentage against F05: Rated voltage)

*

Setting becomes valid when F37 is set at 0, 1, 3 or 4.

Torque Boost

1 : For motor with self-cooled fan, standard motor

2 : For motor with forced-cooled fan

0.00%(Inactive), Approx. 1 to 135% of inverter rated current

5.00.1 min 0.5 to 75.0min

Electronic Thermal Overload for

motor protection

(Select the motor property)

(Overload detection level)

(Starting frequency)

(Braking level)

(Braking time)

(Carrier frequency)

(Sound tone)

(Thermal time constant)

(Peak)

(Bottom)

(Gain to output voltage)

0 : Inactive (Trips immediately without restart when power fails.)

1 : Inactive (Trips without restart when power recovers.)

4 :

Active (Restarts at frequency output at power failure, for general load)

5 : Active (Restarts at starting frequency, for low-inertia load)

Restart Mode after

Instantaneous Power Failure

0.0 to 400.0Hz

0.00.1 Hz

0.000.01 %

0.00.1 Hz

1.00.1 Hz

2

0.000.01 s

01%

180

1%

0.0 to 400.0Hz

Frequency Limiter

-100.00 to 100.00%

Bias

(for Frequency Command 1)

0.1 to 60.0HzStarting Frequency

1001%

0 to 200%

Terminal [FMA]

0.75 to 15kHz 1 kHzMotor Sound

0 : Level 0

1 : Level 1

2 : Level 2

3 : Level 3

0.0 to 60.0Hz

0 to 100%

0.00 (Inactive), 0.01 to 30.00s

DC Braking

(Monitor object)

(Operation condition)

(Allowable average loss)

(for braking resistor)

(Discharging capability)

(Limiting level)

0

--

2

--

Selects from the following items by code.

0 : Output frequency (before slip compensation)

1 : Output frequency (after slip compensation)

2 : Output current

3 : Output voltage

6 : Input power

7 : PID feedback value

9 : DC link circuit voltage

14 : Analog output test (+)

Analog Output Signal Selection

for [FMA]

1

--

0 : Variable torque load

1 : Constant torque load

2 : Auto-torque boost

3 : Auto-energy saving operation

(Variable torque load during acceleration and deceleration)

4 : Auto-energy saving operation

(Constant torque load during acceleration and deceleration)

5 : Auto-energy saving operation

(Auto-torque boost during acceleration and deceleration)

Load Selection/Auto Torque

Boost/Auto Energy Saving

Operation

0 : Inactive

1 : At constant speed (Inactive during acceleration/deceleration)

2 :

During acceleration and at constant speed (Inactive during deceleration)

20 to 200% (Inverter rated current standard)

Current Limiter

Electronic Thermal Overload

Relay

999

1kWs0 (Braking resistor built-in type)

1 to 900kWs, 999(cancel)

0.0000.001 kW0.000 (Braking resistor built-in type)

0.001 to 50.000kW

Fundamental Functions: F codes

0.1 to 60.0HzStop Frequency

0.20.1 Hz

20

Loading...

Loading...