Pipe material

It is necessary to use seamless copper pipes and it is desirable that the amount of

residual oil is less than 40mg/10m. Do not use copper pipes having a collapsed,

deformed or discolored portion (especially on the interior surface). Otherwise, the

expansion valve or capillary tube may become blocked with contaminants.

As an air conditioner using R410A incurs pressure higher than when using

conventional refrigerant (R22), it is necessary to choose adequate materials.

Thicknesses of copper pipes used with R410A are as shown in the table. Never use

copper pipes thinner than that in the table even when it is available on the market.

Thicknesses of Annealed Copper Pipes (R410A)

Pipe outside diameter (mm (in.)) Thickness (mm)

6.35 (1/4) 0.80

9.52 (3/8) 0.80

12.70 (1/2) 0.80

15.88 (5/8) 1.00

19.05 (3/4) 1.20

* JIS H3300 C1220T-O or equivalent

* Please select the pipe size in accordance with local rules.

PIPE INSTALLATION5.

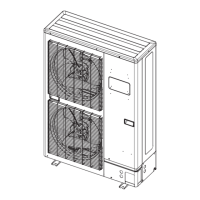

Opening a knockout hole5. 1.

CAUTION

Be careful not to deform or scratch the panel while opening the knockout holes.•

To protect the piping insulation after opening a knockout hole, remove any burrs •

from the edge of the hole. It is recommended to apply rust prevention paint to

the edge of the hole.

Pipes can be connected from 4 directions, front, lateral side, rear side and bottom. •

(Fig. A)

When connecting at the bottom, remove the service panel and piping cover on the •

front of the outdoor unit, and open the knockout hole provided at the bottom corner

of the piping outlet.

It can be installed as shown on “Fig. B” cutting out the 2 slits as indicated on “Fig. C”. •

(When cutting slits, use a steel saw.)

Service panel

Fig. A

Slit

Slit

Fig. B

Bottom

connection

Fig. C

Front

connection

Bottom

connection

Lateral

connection

Rear

connection

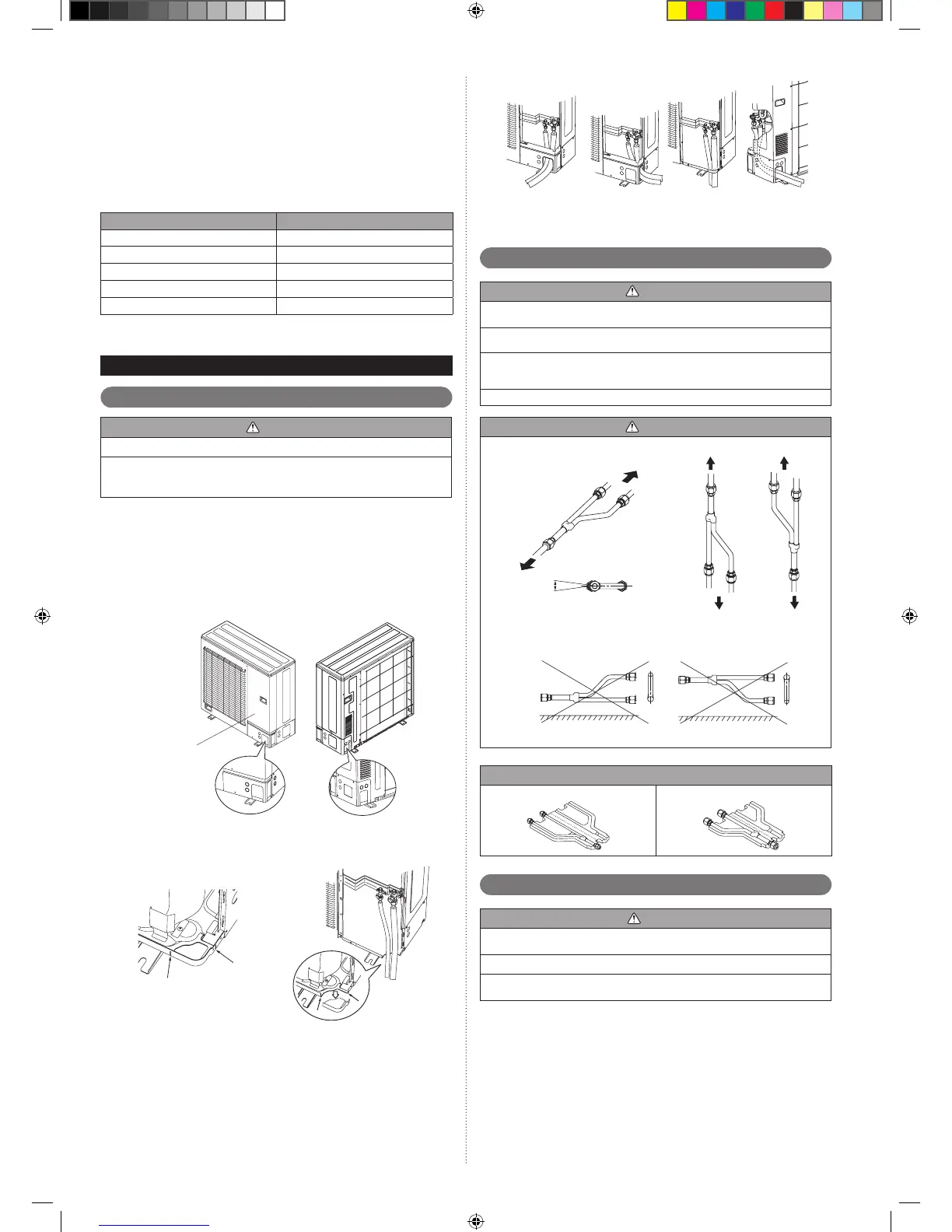

Separation tube connection5. 2.

CAUTION

Use genuine separation tubes for the refrigerant piping branches. Separation •

tubes may be used for piping between the outdoor unit and branch box.

Select number of separation tubes and purchase it before starting the installation •

work.

Any vertical piping shall be in the part of the main piping. If a main pipe is bent, keep •

the straight part more than 10 times the diameter of the connected pipe. A variance in

the amount of refrigerant may be caused if the straight part is short.

For details, refer to the Installation Manual of separation tubes.•

CAUTION

Separation tube

Horizontal

line

OK

Horizontal

±15°

A

B

Vertical

or

A

A

B

B

A : Outdoor unit or Separation tube

B : Branch box or Separation tube

NO GOOD

Name and shape

Liquid pipe

Gas pipe

Flare connection (pipe connection)5. 3.

CAUTION

Do not use mineral oil on a ared part. Prevent mineral oil from getting into the •

system as this would reduce the lifetime of the units.

While welding the pipes, be sure to blow dry nitrogen gas through them.•

The maximum lengths of this product are shown in the table. If the units are •

further apart than this, correct operation cannot be guaranteed.

Loading...

Loading...