16

VMP IOM

a. Make sure two check valves are

installed between the boiler and pump

(one check valve is supplied with the

unit).

b. In a closed system an end of the line

trap should be installed.

c. There are four blow-down valves on the

boiler: Two main bottom blow-down

valves, the gauge glass blow-down

valve, and the water column blow-down

valve. All blow-down connections must

be piped to blow-down seperator.

All these procedures should be done in

accordance with state and/or local codes.

The water column blow-down valve and the

gauge glass blow-down valve should be

connected to the main blow-down line.

Steam Supply

Pipe the steam supply line from the top right

side of the boiler.

Steam Safety Valve

1. Before installing, be sure that all pipes

and connections have been blown

clean. Pipe compound or dope is used

on external threads only. Be sure inlet of

valve is free of any foreign material.

2. Do not use a pipe wrench! When

making installation, use proper type and

size wrench.

3. The valve should be installed in a

vertical upright position in the

connection provided on the top left side

of the boiler with no unnecessary

intervening pipe. Under no

circumstances should there be a shut off

valve or restriction of any kind between

the safety valve and the connection

provided.

4. Do not cap or plug drain hole in the side

of valve body.

5. Since the purpose of this safety valve is

to protect against an overpressure

situation, it will loudly discharge hot

steam in doing so. Therefore, it is

recommended that a discharge pipe be

securely installed and run to a safe point

of disposal.

6. When a discharge pipe is used, it must

be of a pipe size equal to or greater than

that of the valve outlet. Use schedule 40

discharge pipe only. Do not use

schedule 80, extra strong or double

extra strong discharge pipe or

connections. It must be as short and

straight as possible and so arranged as

to avoid undue stress on the valve. It

must have an ample provision for

draining condensate at or near the valve

outlet. It must terminate freely to

atmosphere with no intervening valve of

any description and it must be securely

anchored and supported.

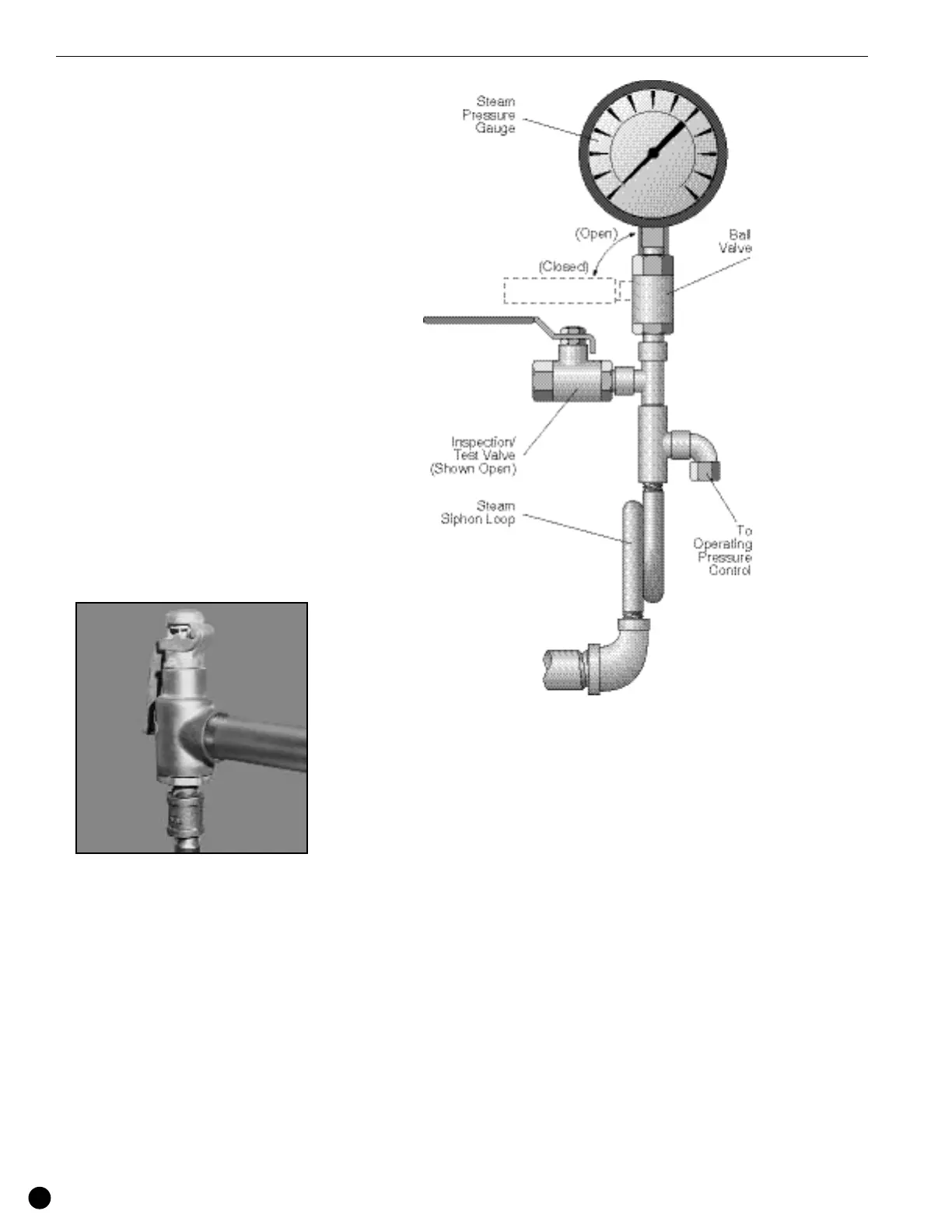

Steam Pressure Gauge

Assembly

The gauge should be facing front towards

the panel box and/or operator of the boiler.

Except as noted, each assembly or any of

its component parts may be oriented, other

than as shown to provide improved

operating clearances and/or view of gauge.

Before installing steam gauge on the

siphon, add a small amount of water to the

siphon to create a water seal to buffer the

gauge element. This must be done to

prevent inaccurate pressure readings and

/or premature failure of the gauge. Install

the steam gauge into the siphon on the

water column.

Installation

Loading...

Loading...