22

Corrosion of flue pipe

In the case of a combustion flue pipe, acid

may develop over a long period of time per

the following process. Chlorine containing

gases, such as halocarbon refrigerants,

carbon tetrachloride, trichloroethylene, or

perchloroethylene, when drawn into

combustion air are broken down into

elemental chlorine gas which exits up the

flue pipe. If the flue pipe is cold, as it would

be if the combustion process had been off

for some time, the water vapor condenses

in the flue pipe during the first few minutes

of ignition and the chlorine in the

combustion gas dissolves in the water

forming hydrochloric acid. As the

combustion system flue line increases in

temperature, the water vapor no longer

condenses because the flue temperature is

above the dew point of the combustion gas.

The combustion gas then dries out

(dehydrates) the hydrochloric acid solution

leaving behind dry chloride salt.

When the next cold start-up occurs, the

process repeats except that more and more

chloride collects and concentrates along

the flue. As the quantity of chloride

increases it does not dehydrate completely

as the flue heats up and a corrosive poultice

develops which attacks the steel and will

also attack the boiler.

Concentration levels of only a

few ppm of chlorine containing compounds

in combustion air can produce serious

corrosion over long periods of time. High

chlorine containing compounds such as

carbon tetrachloride or perchloroethylene

would be prime suspects.

In addition, normal combustion creates

carbon dioxide which may condense in a

cold flue to form carbonic acid.

Installation Check Points

1. Make sure all piping connections are

complete and tight.

2. Make sure the pressure controls are

adjusted properly.

3. Make sure all electrical connections in

the control panel box, the water column,

and elsewhere are secure.

4. Make sure the door in the boiler room is

closed. Combustion air contaminates

can cause damage to the boiler jacket

and stack.

NOTE

After installation is complete and prior

to operation the pressure vessel should

be cleaned.

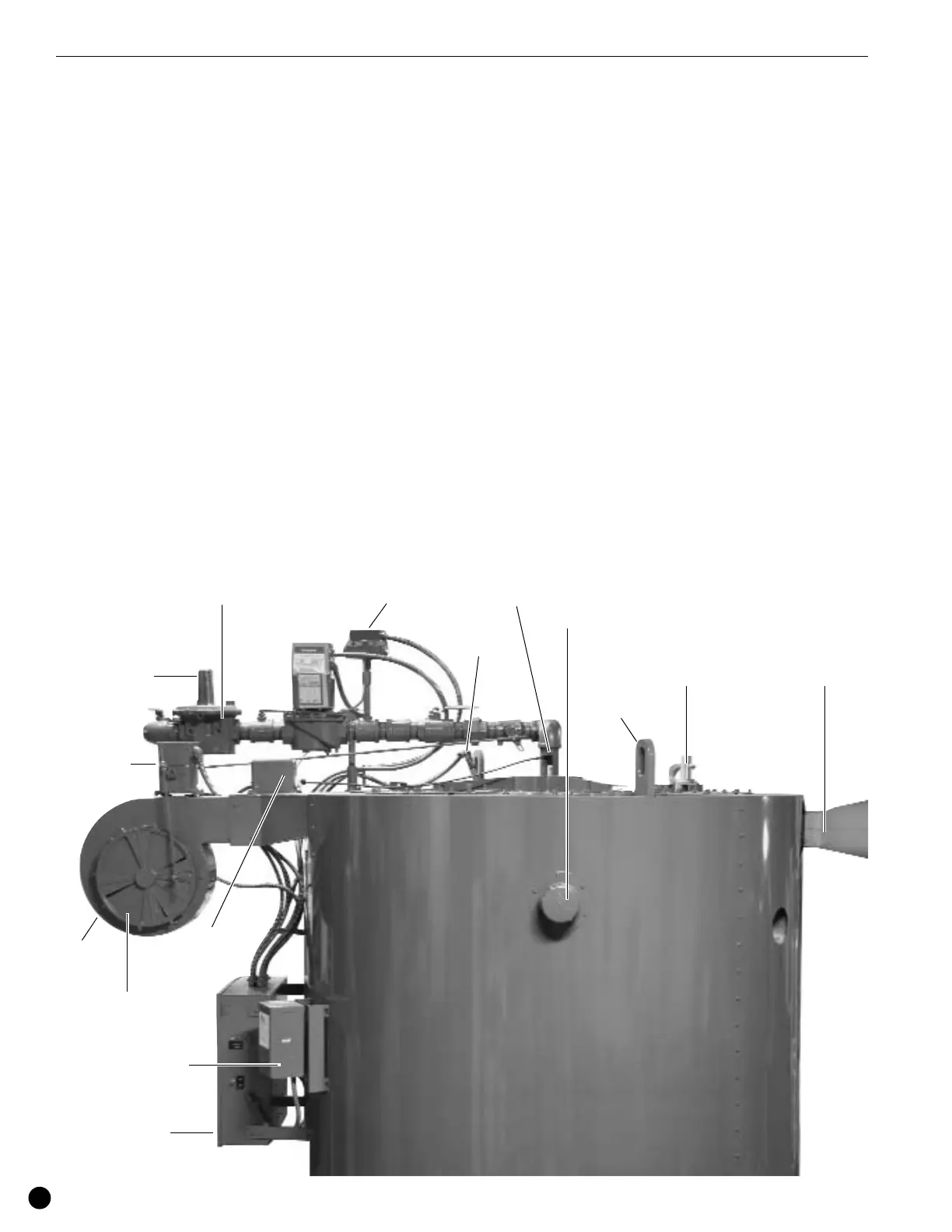

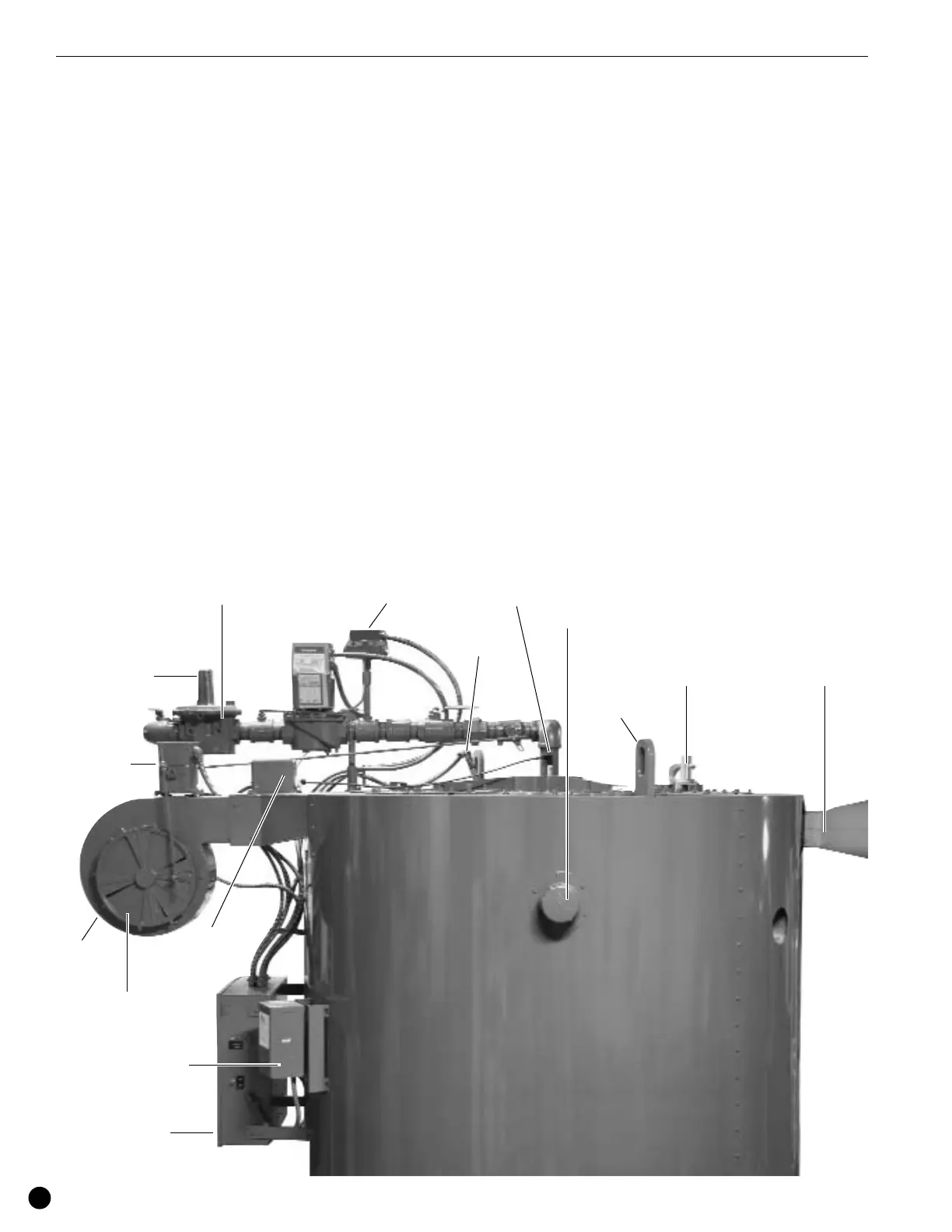

VMP IOM

Installation

Blower

Air Gate

Electric

Control

Panel

Gas Train Available with Optional

High-Low-Off, or Modulation

Primary steam outlet

(Valve not shown)

Safety Valve(s)

Exhaust stack

adapter

Control circuit

transformer

Gas Valve

Modulation

Motor

Gas Regulator

Scroll

Lifting Lug

Pressure Switch

UV Scanner

Ignition

Electrode

Ignition

Transformer

Loading...

Loading...