VMP IOM

21

Electrical Requirements

1. Connect wiring as shown in the wiring

diagram which is furnished inside the

electrical control panel box.

2. Be sure to install a separate disconnect

for each piece of equipment. The

disconnects should be installed in

compliance with the NEC (National

Electric Code) and all local codes.

3. Connections for an optional audible

alarm are provided in the control panel

and are clearly indicated on the diagram.

Fresh Air Supply

for Boiler

It is most important to provide free access of

air to the boiler. To burn fuel properly, it

requires one square inch opening of fresh air

for every 3,000 BTU input of fuel. (6.4cm

2

for

every 756 Kcal).

Proper ventilation of the boiler room is

essential for good combustion. Install two

fresh air openings, one at a low level 24”

(610 mm) from floor and one at a higher

level in the boiler room wall.This will provide

a flow of air to exhaust the hot air from the

boiler room. Boiler room temp not to

exceed 100°F.

The following openings are recommended for

each size boiler:

Make Up Air Openings

BHP FT

2

M

2

40 5 .46

50 5 .46

60 7.5 .69

80 12.5 1.11

100 16 1.49

130 21 1.95

150 24 2.23

Be sure total BHP = proper make up air

opening size.

These measurements are subject to state

and local regulations. The installation of

exhaust fans in a boiler room is not

recommended.

An exhaust fan, or similar equipment can

create down draft in the stack or restrict the

burner’s air supply which will result In poor

combustion. It is essential that only fresh air

is allowed to enter the combustion air

system. Foreign substances, such as

combustible volatiles and lint, in the

combustion system can create hazardous

conditions.

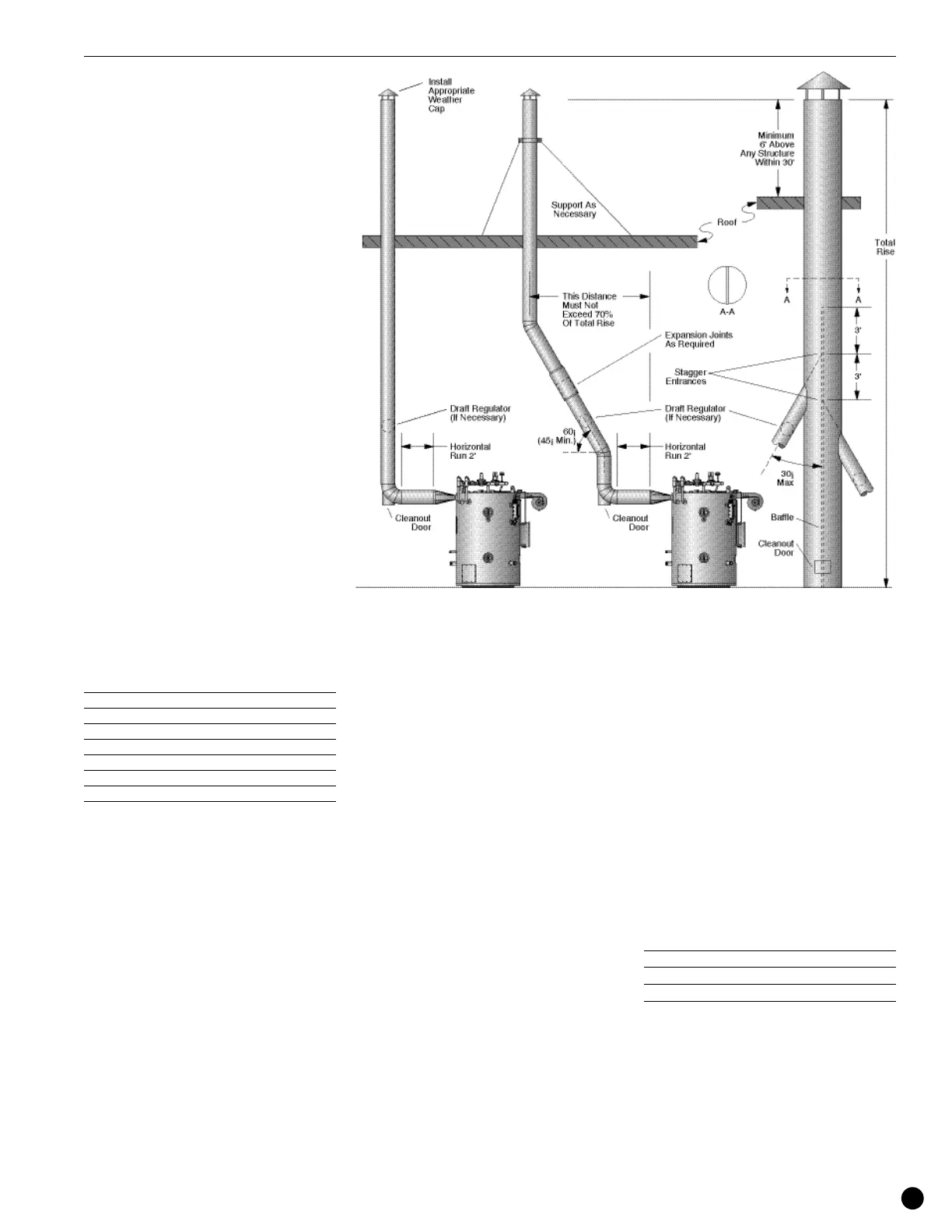

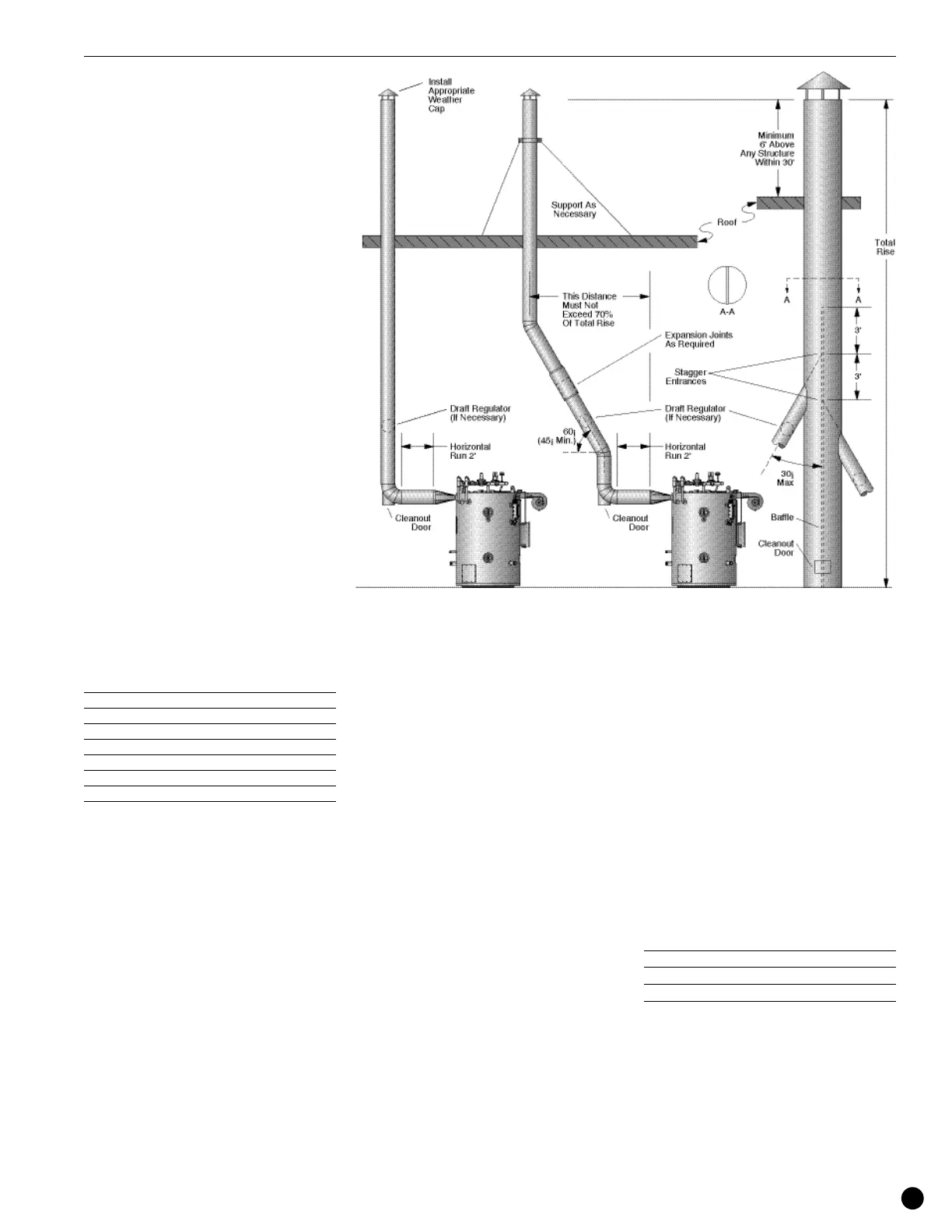

Conventional Venting

The stack should rise continuously to the

connection with the chimney, and should

contain no more than two bends at 45°

angles or less. If required as the result of

space limitations, one 90° elbow can be

fitted at the back of the boiler. There should

be two feet of straight, horizontal flue before

any bends or turns. Any alternative stack

arrangement must supply a negative .02 -

.04” W.C. pressure (0.508 to 1.016 mm)

with the burner off.

The run in the total distance of stack ducting,

as measured in a straight line from the outlet

of the boiler to the outlet of the stack, should

not exceed 70% of the rise. With the

exception of a duct run described in Item a,

horizontal sections of ducting must be

avoided, and should not exceed four feet of

total run.

The stack and chimney must be

constructed from material that is rated for

1000°F operating temperature. Check all

local codes for exact requirements.

Adequate provision must be made for the

support of the weight of the chimney and

stack to avoid having too great a load

imparted to the flue outlet connection of the

boiler.

The proper flue size and draft control is

most important for proper burner operation.

The flue must be

as large or larger than the outlet on the

boiler. Avoid flue piping and elbows by

placing the boiler as close as possible to the

chimney.

A mechanical draft regulator should be

installed in the flue outlet. Do not install the

draft regu-lator prior to the first turn of the

flue.

BHP Boiler Flue Size

IN MM

40, 50, 60 12 305

80, 100, 130 14 356

150 16 406

The installer should check the draft with a

meter at negative .02 -.04” W.C. pressure

(0.508 to 1.016 mm) with the burner off.

Installation

Loading...

Loading...