26

VMP IOM

Starting the

Gas Fired Boiler

STOP! Make sure you have read and

followed all previous safety information.

Check with local authorities where

approval for start-up is required. In

some localities, final inspection of

services may be required.

In general, ensure that the boiler area is

in conformance with established boiler

room requirements. Review national

and local codes.

Carry out the following procedure on the

initial start up of the boiler and on every

subsequent occasion when restarting the

boiler after a shut down.

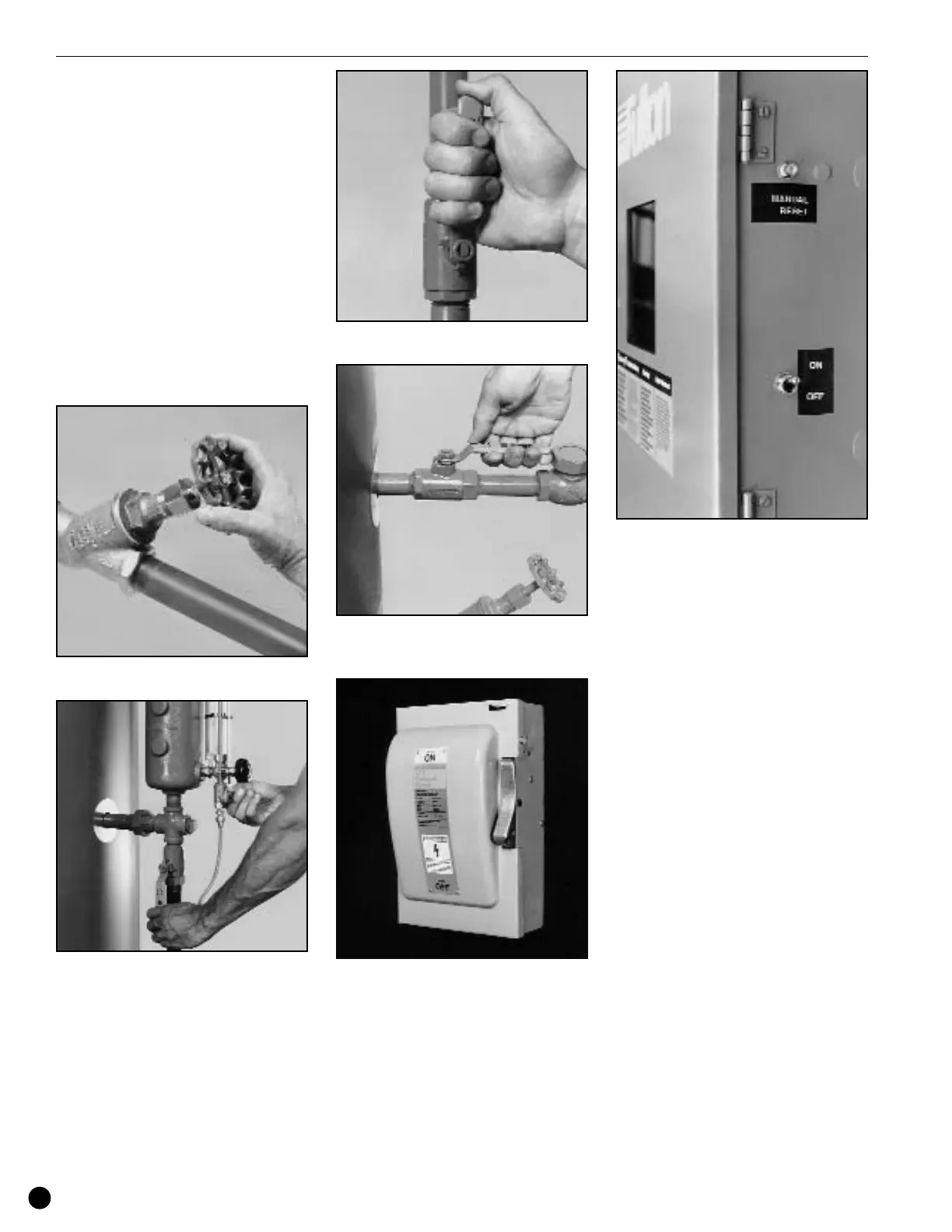

1. Close the blow-down valves.

2. Close the water gauge drain valve.

3. Open main steam stop valve at the top

of the boiler.

4. Open the water feed valve on the boiler.

5. Open valves on makeup water line to

return if return system is used.

6. Place feedwater pump fused switch in

the "on" position.

NOTE

The pump will continue to operate until

the water reaches the correct level in the

boiler. This level is approximately the

center of the water gauge glass.

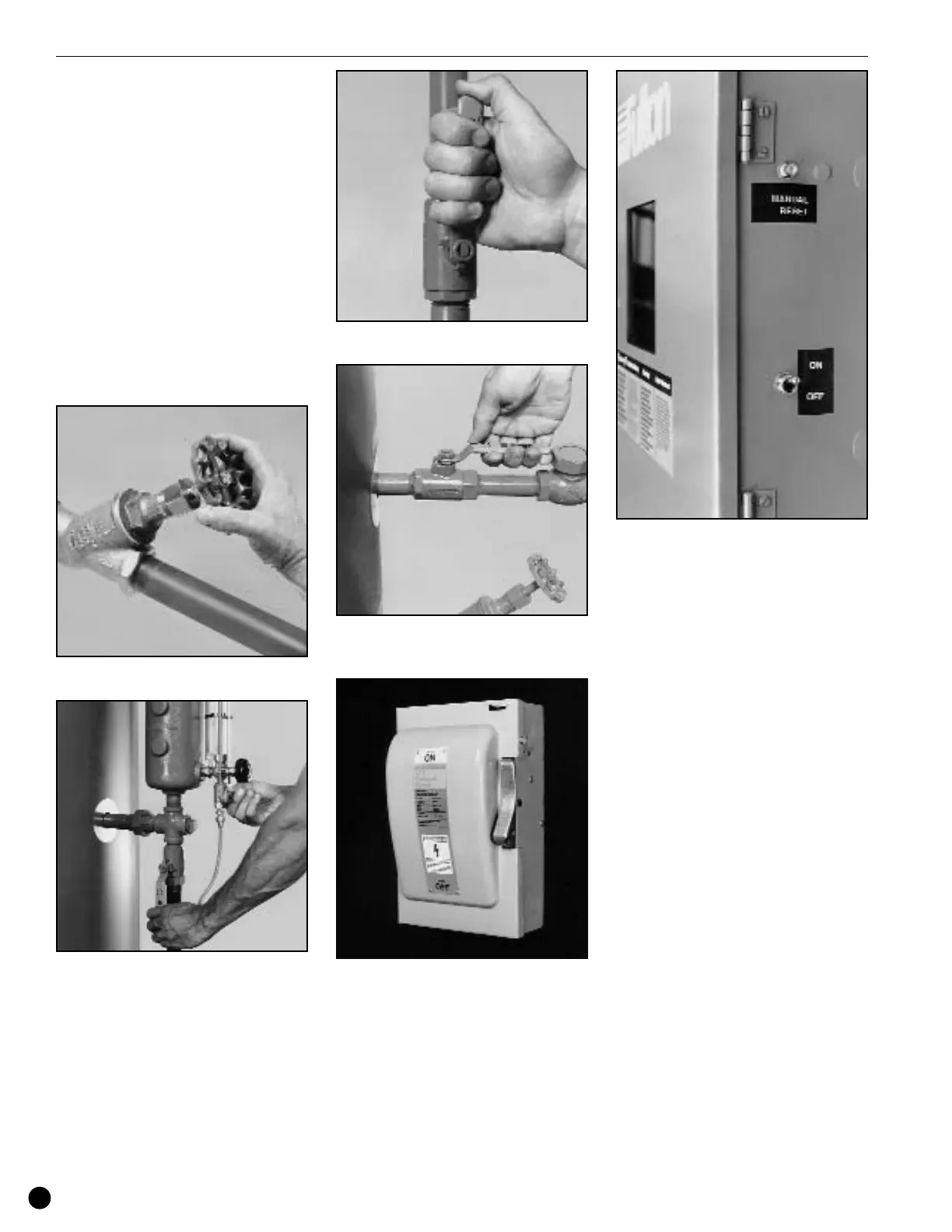

7. Activate the boiler power on switch,

located on the side of the panel box.

8. With the unit full of water the low water

safety relay(s) will be in a lock-out

mode. Press the low water safety relay

manual reset button located on the side

of the control panel box.

Gas Burner Set Up

1. Open the manual gas cocks on the pilot

and main lines of the gas head.

2. Switch on the main power to the burner.

The water level relay is equipped with a

manual reset. Depress the button on the

box.

3 The flame programmer is the

main control in the panel box. The

programmer in conjunction with a sensing

device, either a flame rod or a UV

scanner, "supervises" the ignition

sequence - proves the flame is

satisfactory, and finally"monitors" the

established flame. Should any fault occur,

either during the ignition sequence or

during normal running, the programmer

will immediately go to "lock-out" and the

burner will shut down.

NOTE

To reset the boiler burner after a “Lock

out” signal, push the reset button on the

control.

Operation

Loading...

Loading...