38

Pilot Adjustment for

Fulton LoNOx Burner.

1. Close downstream shut off valve.

2. Start boiler and check flame signal on

pilot, lock programmer into pilot hold.

3. Adjust air and gas regulator as needed

to obtain a strong pilot signal.

4. Slowly open downstream shut off valves

and take the flame programmer off of hold.

Main Flame Adjustment

For LE Models

1. Place a combustion analyzer in the

exhaust of the boiler.

2. Do not adjust main gas regulator. To

increase fuel to the burner, the servos

that control modulating gas valves

require adjustment.

Burner Tile Replacement

For LE Models

1. Remove scroll assembly.

2. Break off top holding clips.

3. Remove ceramic fiber burner tile.

4. Replace burner tile bottom holding clips

if needed.

5. Replace with new burner tile.

6. Carefully replace scroll assembly so that

the ceramic fiber burner tile is not

damaged.

Servo Motor Replacement

For LE Models

If it is determined that a servo motor needs to

be replaced, the first step in this process is to

verify the model number of the new servo

motor is the same as the old servo motor.

The model number starts with the letters SQM

and is displayed on a label on the side of the

motor. Once the new motor has been verified

to be correct, turn power to the boiler off.

1. Turn off all electricity to the boiler.

2. Remove the cover on the servo motor to

be changed.

3. Remove the green wiring plugs and the

conduit termination point from the motor

by pulling them towards you. A black

grounding wire runs from the motor to

the conduit termination point. Pull it off

from the conduit termination point.

4. Also note the location of the jumper on

the left side of the motor.

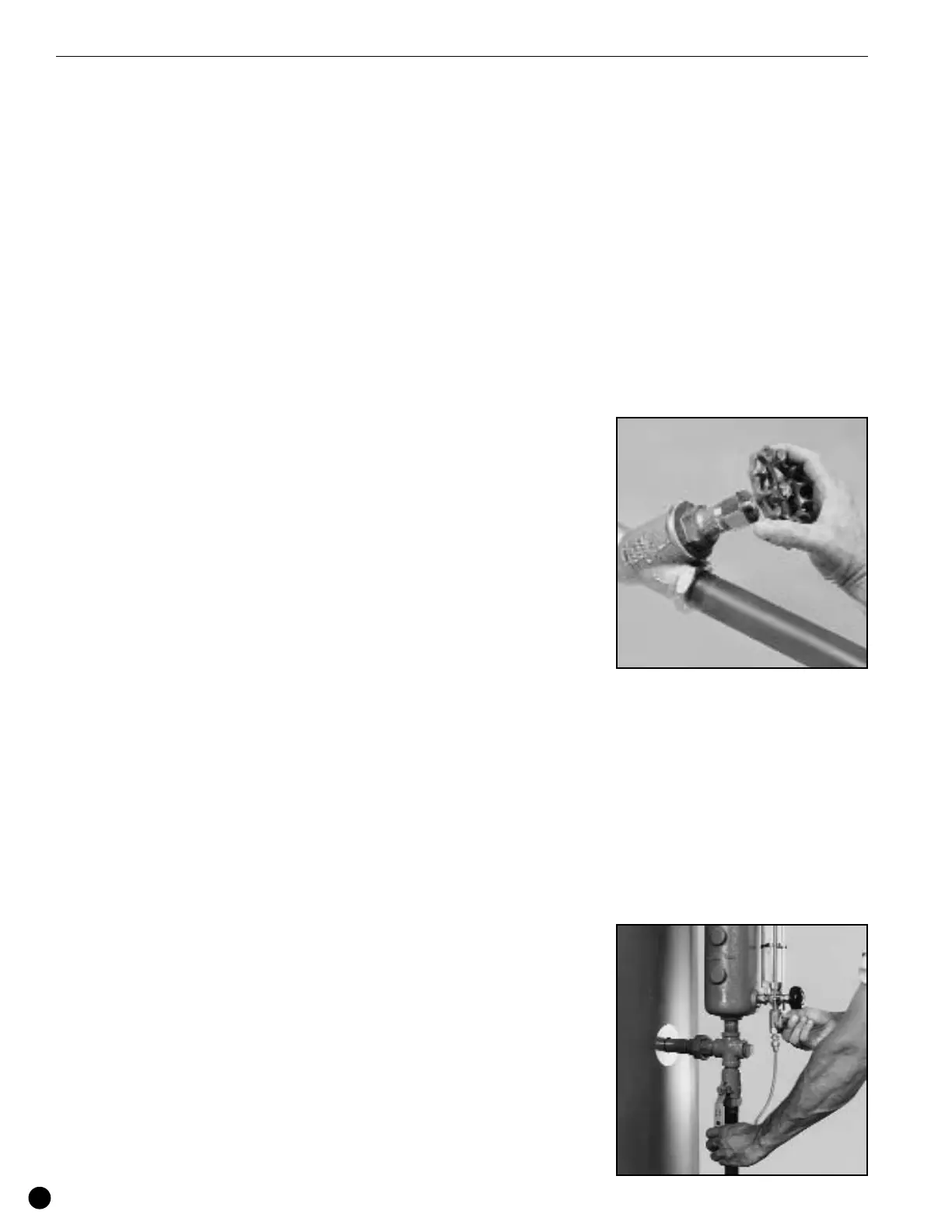

5. Loosen the allen screws on the motor

end of the motor to valve coupling.

6. Unbolt the motor from the mounting

bracket and remove the motor.

7. Turn the valve so it is in the closed

position and can rotate clockwise to open.

8. Mark the coupling or valve shaft if

needed so the position of the valve can

be determined when the servo motor is

installed.

9. Bolt the new servo motor on to the

mounting bracket with the motor shaft

inserted into the coupling.

10. Rotate the valve shaft/coupling assembly

closed as stated above.

11. While holding the valve closed, tighten

the allen screws on the coupling.

12. Install the wired green wiring plugs and the

conduit termination point on the new motor.

Connect the black grounding wire from the

motor to the conduit termination point.

13.Verify the jumper on the motor is located

on the same pins as the motor that was

replaced.

14.Turn power to the boiler on.

15.The screen will display ‘system test’.

The fault “Fault Feedback Air Actuator’

will be displayed. DO NOT RESET

THIS FAULT YET. Press Escape twice

to clear the fault from the screen.

16. Press Escape to get to the main menu.

Under Params&Display > Actuators >

Addressing, select either the gas actuator

or air actuator depending upon which was

replaced. The control will run an actuator

check then display ‘Start Address

Assignment with ENTER’. Press Enter.

The display will then have you press the

addressing button on the actuator. This is

the red button on the actuator. The screen

will then display ‘Actuator Address

Assignment Successful’.

17.Press Escape until the main menu is

reached. Under OperationalStat >

Status/Reset, reset the fault.

CAUTION

The boiler emissions may not be correct

after changing the servo motor. Verify the

emissions throughout the range of

modulation. If emissions are off, the

servo motor can be adjusted by following

the procedure in the Commissioning the

Boiler section of this manual.

18. Attach cover to servo motor.

Recommended Daily

Maintenance Schedule

The following procedures should be carried

out daily. They are designed to prevent the

build up of scale, silt, or sludge in the bottom

of the boiler and in the pipes leading to the

water gauge. In addition to these procedures,

the advice of a water treatment supplier

should be sought and followed. An ASME

Section VIII blow-down receptacle must be

provided for the appropriate pressure.

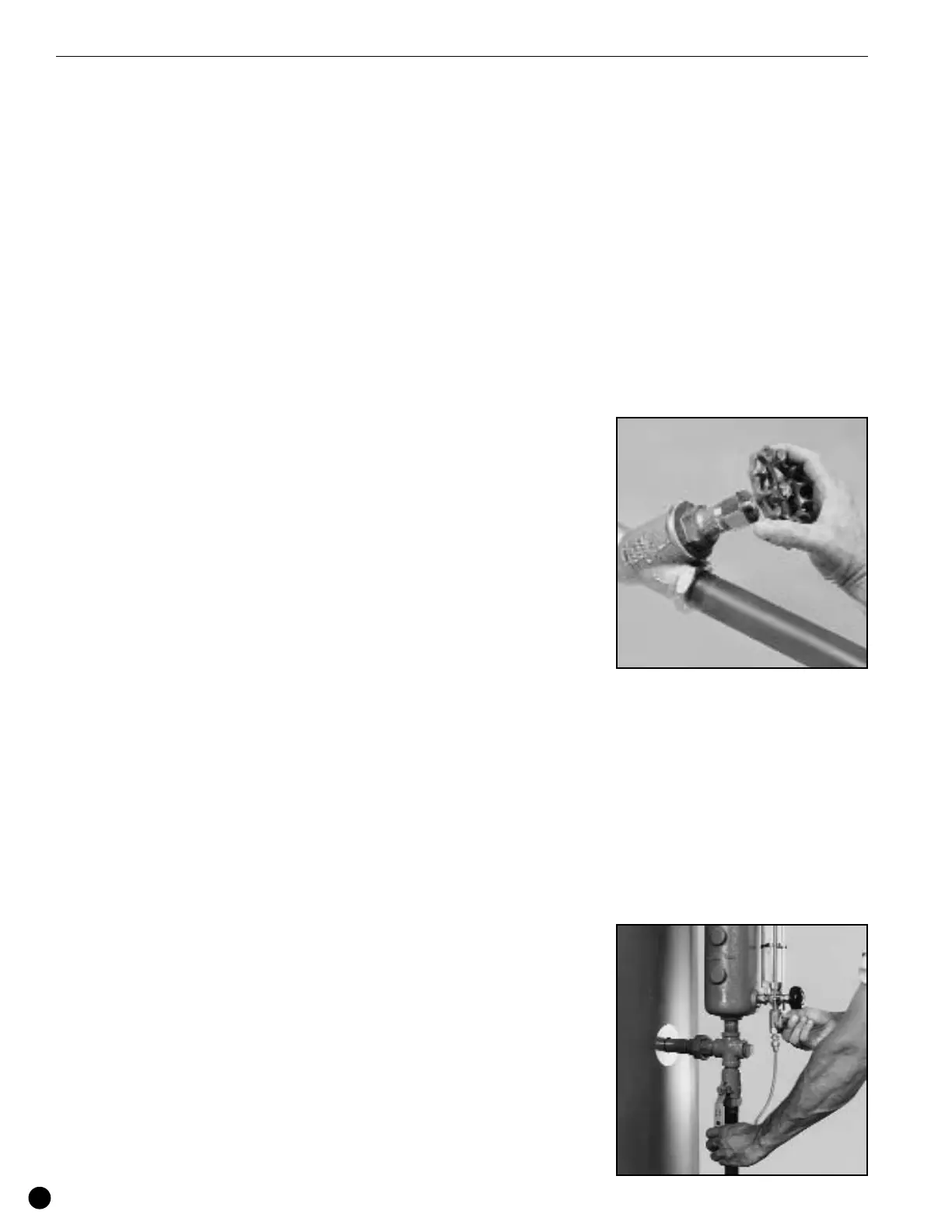

1. Blow down the boiler each morning by

starting the boiler and generating not

more than 10 PSI (.703 kg/cm

2

) of

steam. Turn on tap water to blow-down

separator, then open the boiler blow-

down valves for approximately 10

seconds, then close the valve. Shut off

tap water to blow-down separator.

Blow Down Boiler Daily. Shown is the

blow down "Y" valve.

NOTE

If the boiler is being operated

automatically on a time clock, the blow-

down operation may be done once

during the working day and once at the

end of the day when at 10 PSIG or less.

2. Blow down water column each morning

when boiler is at 10 PSI (.703 kg/cm

2

) by

opening the water column and the water

gauge blow-down valves for approximately

5 seconds, then close the valves.

VMP IOM

Loading...

Loading...