7-4 469 Motor Management Relay GE Power Management

7.2 HARDWARE FUNCTIONAL TESTING 7 TESTING

7

7.2.4 GE POWER MANAGEMENT 50:0.025 GROUND ACCURACY TEST

The 469 specification for GE Power Management 50:0.025 ground current input accuracy is

±

0.5% of CT rated

primary (25 A). Perform the steps below to verify accuracy.

1. Alter the following setpoint:

S2 SYSTEM SETUP\CURRENT SENSING\GROUND CT: 50:0.025

2. Measured values should be

±

0.125 A. Inject the values shown in the table below either as primary values

into a GE Power Management 50:0.025 Core Balance CT or as secondary values that simulate the core

balance CT. Verify accuracy of the measured values. View the measured values in:

A2 METERING DATA\CURRENT METERING

7.2.5 RTD ACCURACY TEST

The 469 specification for RTD input accuracy is

±

2

°

. Perform the steps below to verify accuracy.

1. Alter the following setpoints:

S8 RTD TEMPERATURE\RTD TYPE\STATOR RTD TYPE: 100 ohm Platinum (select desired type)

S8 RTD TEMPERATURE\RTD #1\RTD #1 APPLICATION: Stator (repeat for RTDs 2 to 12)

2. Measured values should be

±

2

°

C or ±4°F. Alter the resistances applied to the RTD inputs as per the table

below to simulate RTDs and verify accuracy of the measured values. View the measured values in:

A2 METERING DATA\TEMPERATURE

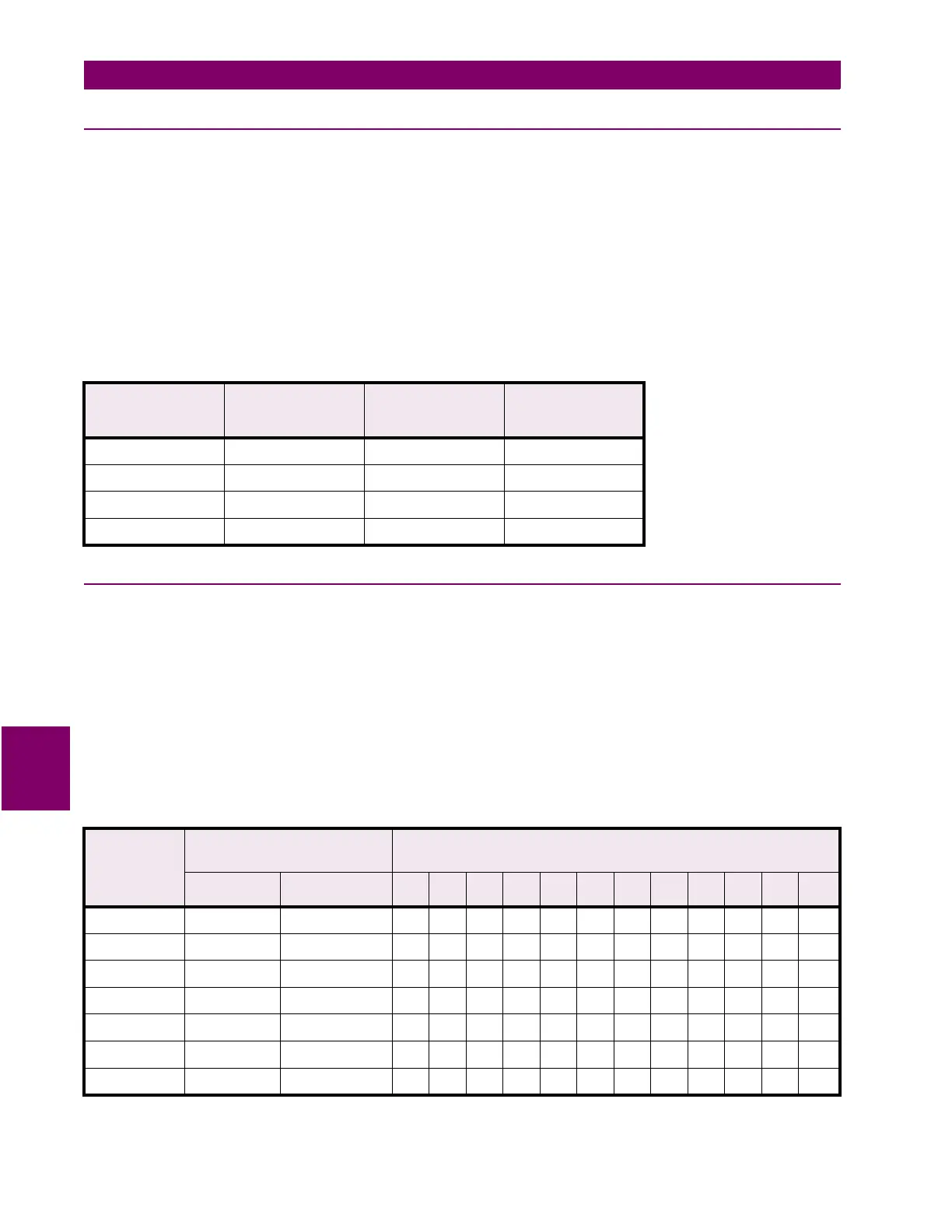

Table 7–5: 50:0.025 CT GROUND CURRENT TEST

PRIMARY

INJECTED

CURRENT

SECONDARY

INJECTED

CURRENT

EXPECTED

CURRENT

READING

MEASURED

GROUND

CURRENT

0.25 A 0.125 mA 0.25 A

1 A 0.5 mA 1.00 A

10 A 5 mA 10.00 A

25 A 12.5 mA 25.00 A

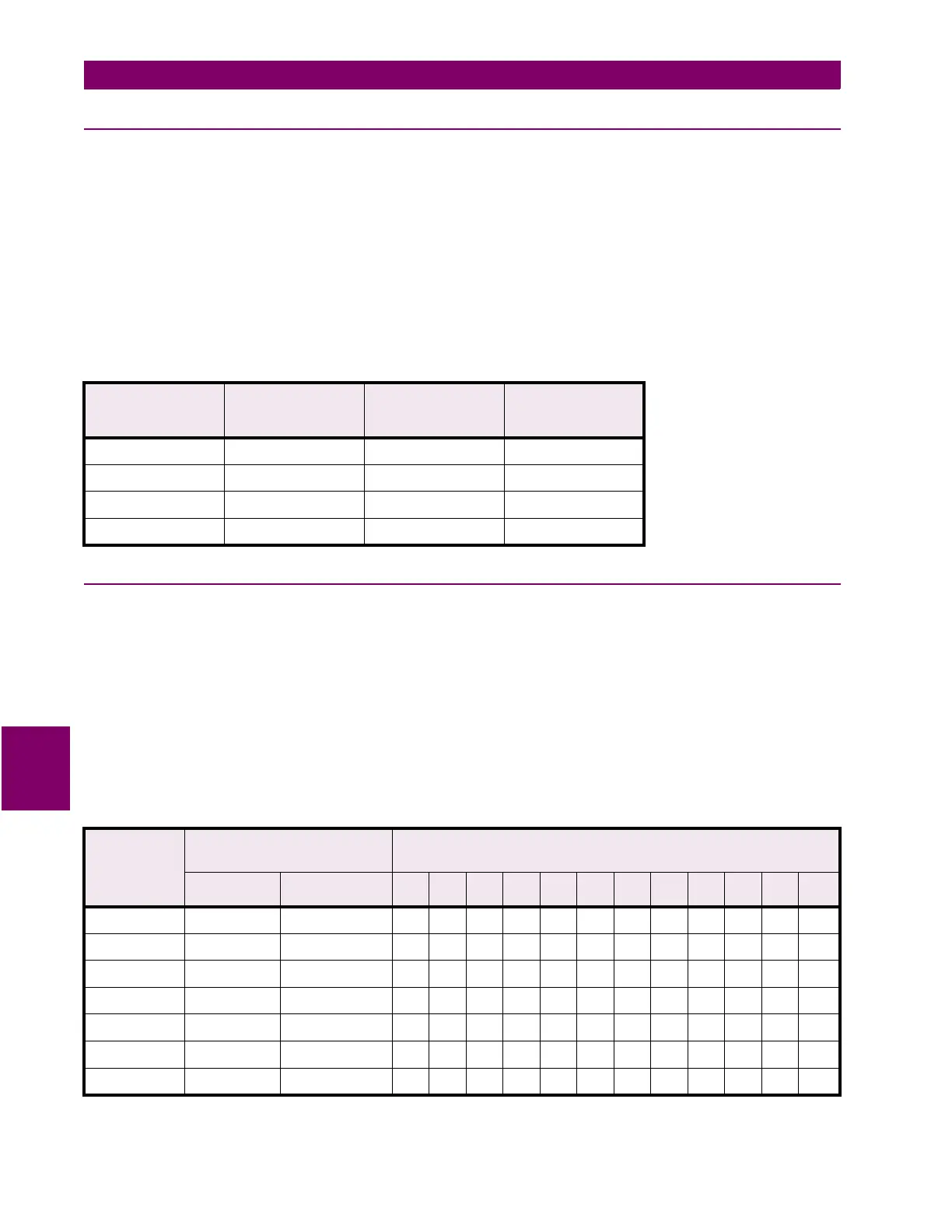

Table 7–6: 100

Ω

PLATINUM TEST

APPLIED

RESISTANCE

100

Ω

PLATINUM

EXPECTED RTD

TEMPERATURE READING

MEASURED RTD TEMPERATURE

SELECT ONE: ____(

°

C ) ____(

°

F )

° CELSIUS ° FAHRENHEIT

1 2 3 4 5 6 7 8 9 10 11 12

80.31 Ω –50°C –58°F

100.00 Ω 0°C 32°F

119.39 Ω 50°C 122°F

138.50 Ω 100°C 212°F

157.32 Ω 150°C 302°F

175.84 Ω 200°C 392°F

194.08 Ω 250°C 482°F

Loading...

Loading...