GE Power Management 469 Motor Management Relay 7-7

7 TESTING 7.2 HARDWARE FUNCTIONAL TESTING

7

3. Verify the ammeter readings as well as the measured analog input readings. For the purposes of testing,

the analog input is fed in from the analog output (see Figure 7–1: SECONDARY INJECTION TEST

SETUP). View the measured values in:

A2 METERING DATA\ANALOG INPUTS

b) 0-1 mA

1. Alter the following setpoints:

S12 ANALOG I/O\ANALOG INPUT1\ANALOG INPUT1: 0-1 mA

S12 ANALOG I/O\ANALOG INPUT1\ANALOG INPUT1 MINIMUM: 0

S12 ANALOG I/O\ANALOG INPUT1\ANALOG INPUT1 MAXIMUM: 1000 (repeat for analog inputs 2 to 4)

2. Analog output values should be

±

0.01 mA on the ammeter. Measured analog input values should be

±

10

units. Force the analog outputs using the following setpoints:

S13 TESTING\TEST ANALOG OUTPUT\FORCE ANALOG OUTPUTS FUNCTION: Enabled

S13 TESTING\TEST ANALOG OUTPUT\ANALOG OUTPUT 1 FORCED VALUE: 0%

(enter desired percent, repeats for analog output 2-4)

3. Verify the ammeter readings as well as the measured analog input readings. View the measured values in:

A2 METERING DATA\ANALOG INPUTS

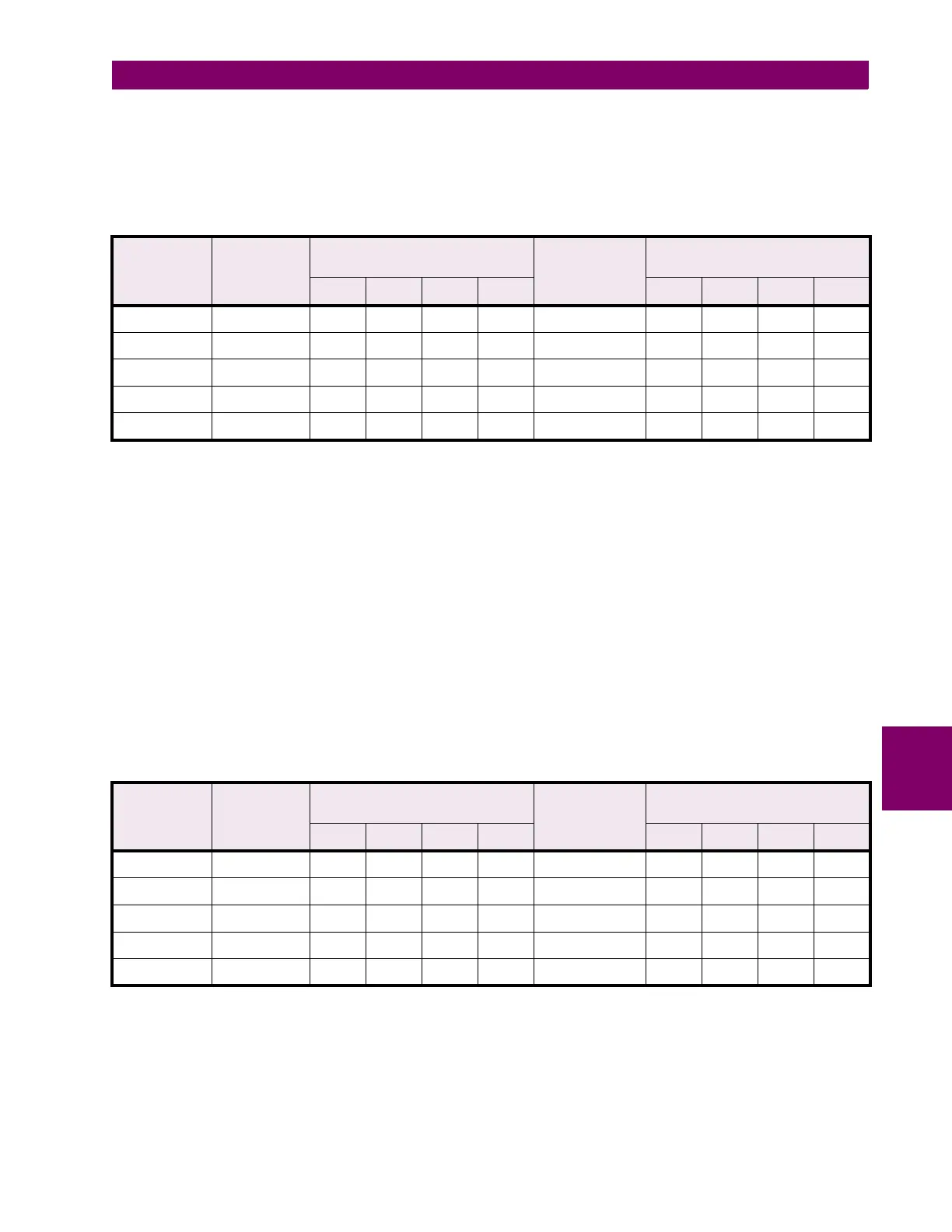

Table 7–11: ANALOG I/O TEST 4-20 mA

ANALOG

OUTPUT

FORCE

VALUE

EXPECTED

AMMETER

READING

MEASURED AMMETER

READING (mA)

EXPECTED

ANALOG

INPUT

READING

MEASURED ANALOG INPUT

READING (units)

1 2 3 4 1 2 3 4

0% 4 mA 0 mA

25% 8 mA 250 mA

50% 12 mA 500 mA

75% 16 mA 750 mA

100% 20 mA 1000 mA

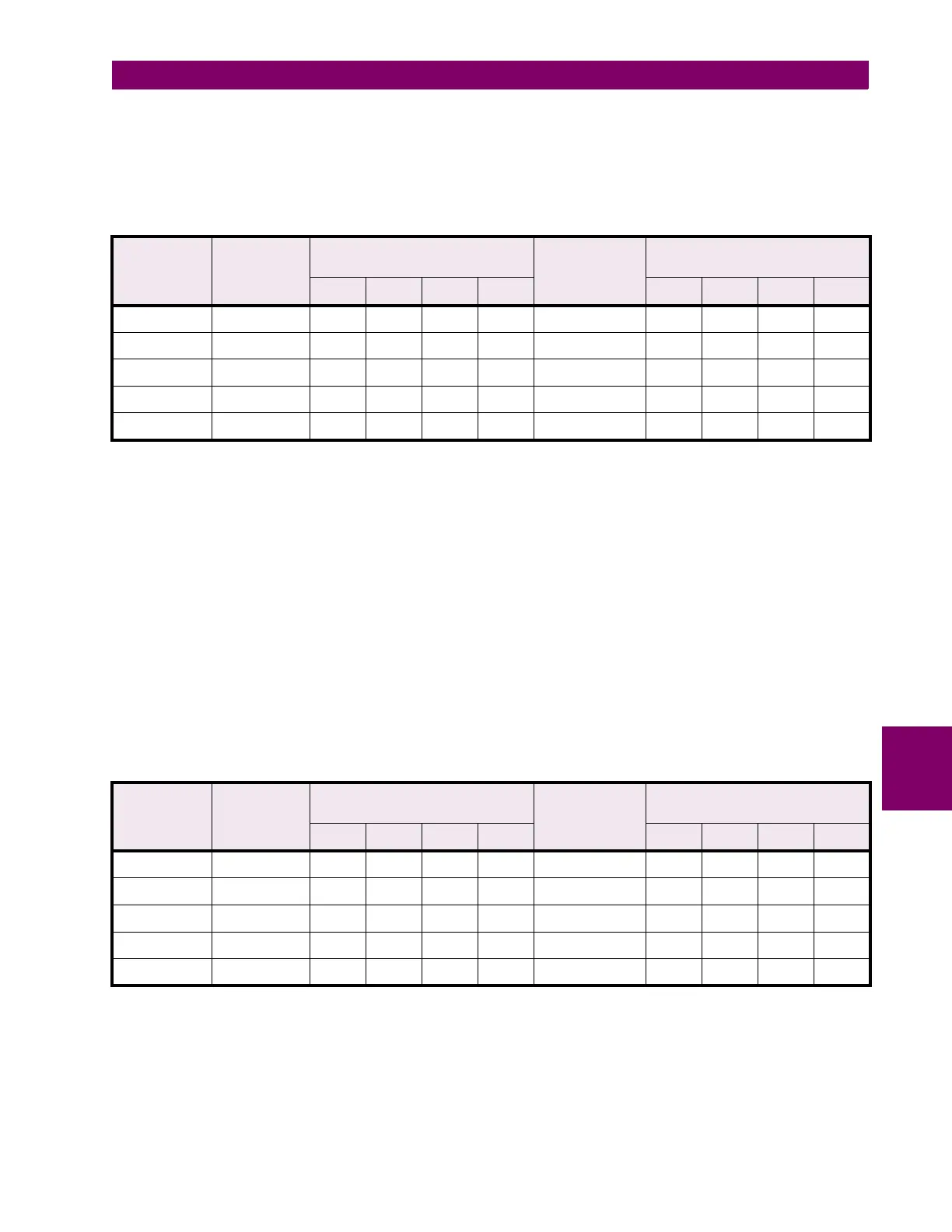

Table 7–12: ANALOG I/O TEST 0-1 mA

ANALOG

OUTPUT

FORCE

VALUE

EXPECTED

AMMETER

READING

MEASURED AMMETER

READING (mA)

EXPECTED

ANALOG

INPUT

READING

MEASURED ANALOG INPUT

READING (units)

1 2 3 4 1 2 3 4

0% 0 mA 0 mA

25% 0.25 mA 250 mA

50% 0.50 mA 500 mA

75% 0.75 mA 750 mA

100% 1.00 mA 1000 mA

Loading...

Loading...