GE Power Management 469 Motor Management Relay 4-39

4 SETPOINT PROGRAMMING 4.6 S5 THERMAL MODEL

4

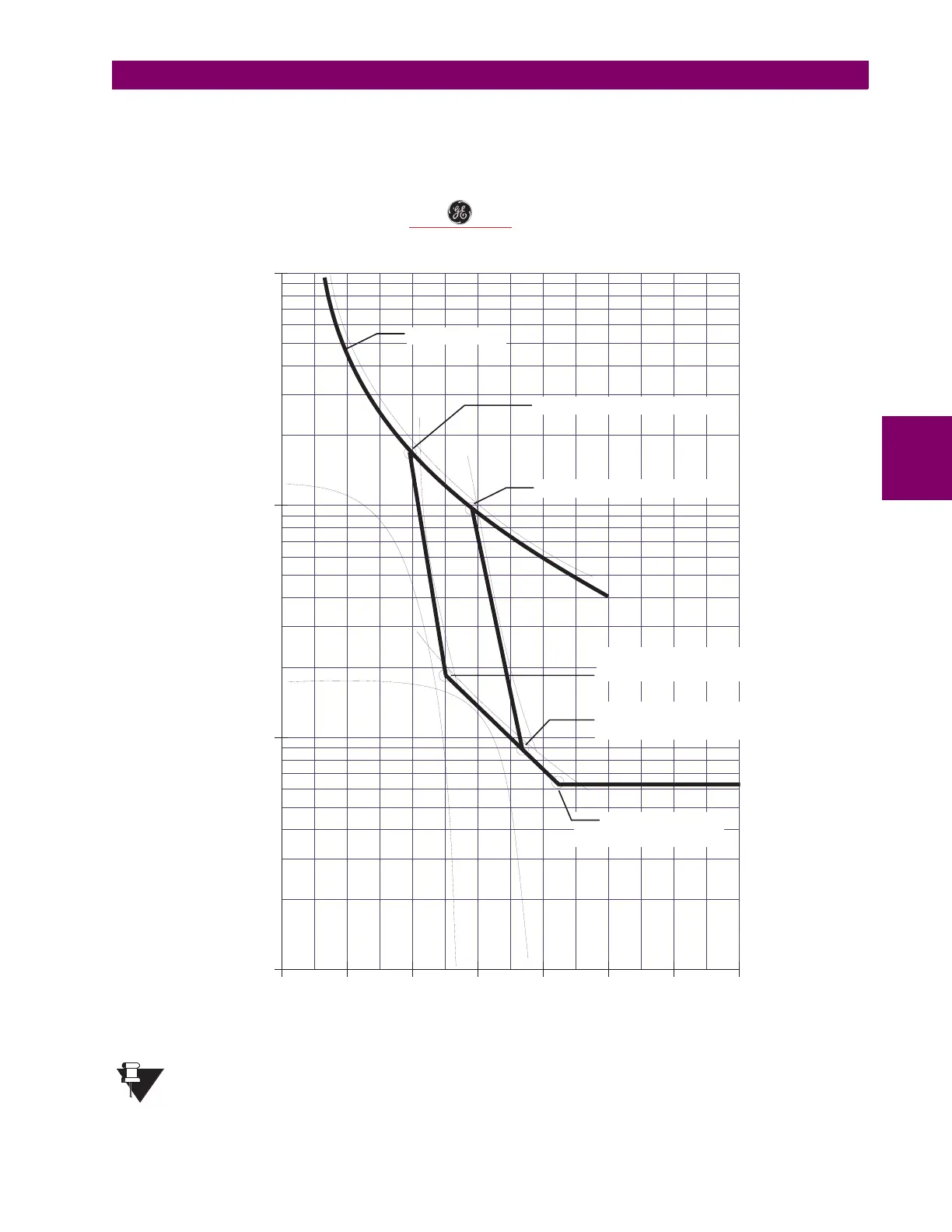

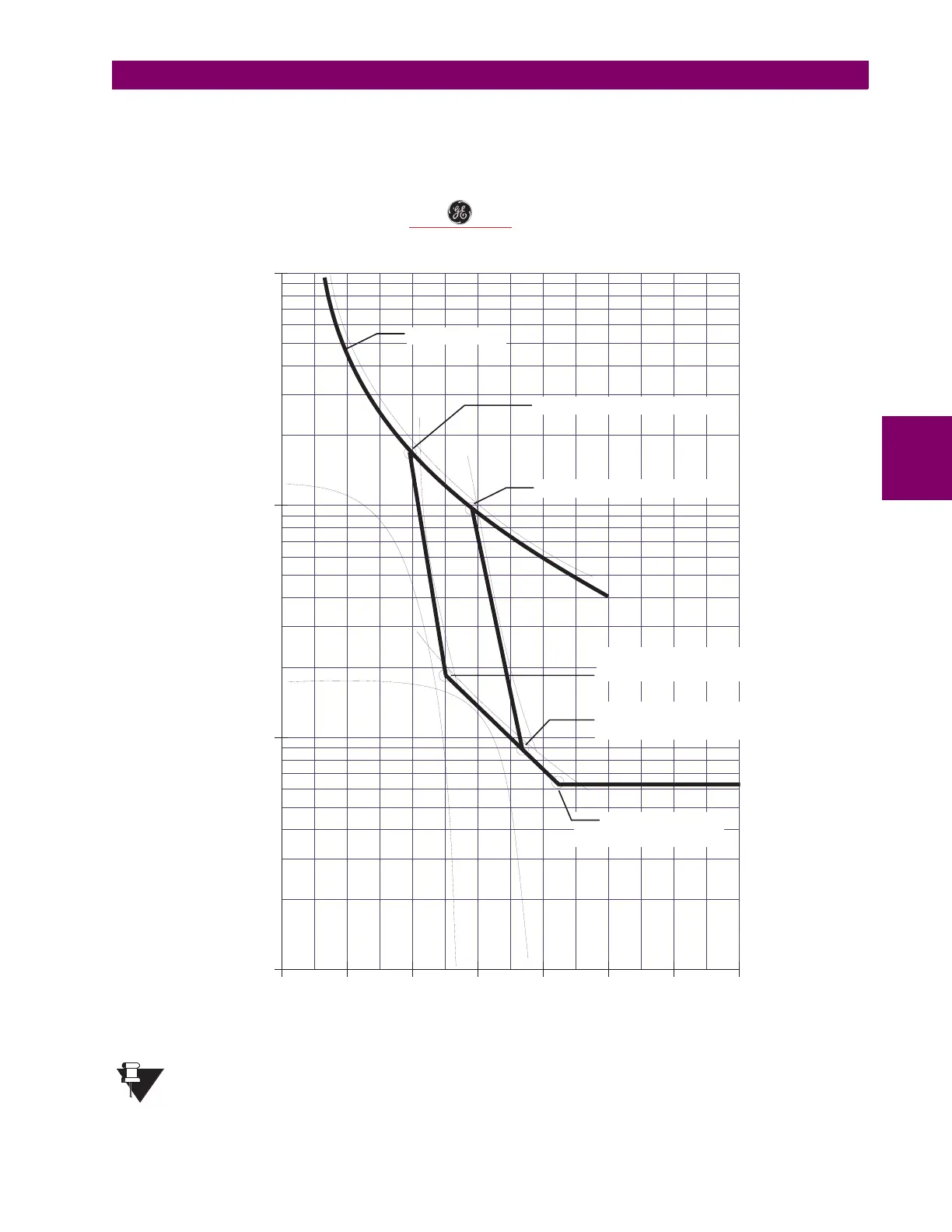

The 469 takes the information provided and create protection curves for any voltage between the minimum

and 100%. For values above the voltage in question, the 469 extrapolates the safe stall protection curve to

110% voltage. This current level is calculated by taking the locked rotor current @ 100% voltage and multiply-

ing by 1.10. For trip times above the 110% current level, the trip time of 110% will be used. (see figure below).

Figure 4–13: VOLTAGE DEPENDENT OVERLOAD PROTECTION CURVES

The safe stall curve is in reality a series of safe stall points for different voltages. For a given

voltage, there can only be one value of stall current and therefore, only one safe stall time.

1

123 456 78

2

3

4

5

6

7

8

9

10

20

30

40

50

60

70

80

90

100

HIGH INERTIA LOAD OVERLOAD CURVES

8800 HP, 13.2 kV, REACTOR COOLANT PUMP

TIME TO TRIP (SECONDS)

MULTIPLES OF FULL LOAD AMPS

200

300

400

500

600

700

800

900

1000

Acceleration Intersect @ 80%V

Custom Curve

Acceleration Intersect @ 100%V

Safe Stall Time @ 80%V,

80%V Stall Current

Safe Stall Time @ 100%V,

100%V Stall Current

Safe Stall Points

Extrapolated to 110%V

806824A3.CDR

GE Power ManagementGE Power Management

NOTE

Loading...

Loading...