5–56 469 MOTOR MANAGEMENT RELAY – INSTRUCTION MANUAL

CHAPTER 5: SETTINGS

(EQ 5.5)

(EQ 5.6)

where: TC

used

= thermal capacity used

TC

used_start

= TC

used

value caused by overload condition

TC

used_end

= TC

used

value dictated by the hot/cold safe stall ratio when

the motor is running (= 0 when the motor is stopped)

t = time in minutes

τ = Cool Time Constant (running or stopped)

I

eq

= equivalent motor heating current

ol_pkp = overload pickup settings as a multiple of FLA

hot / cold = hot/cold safe stall ratio

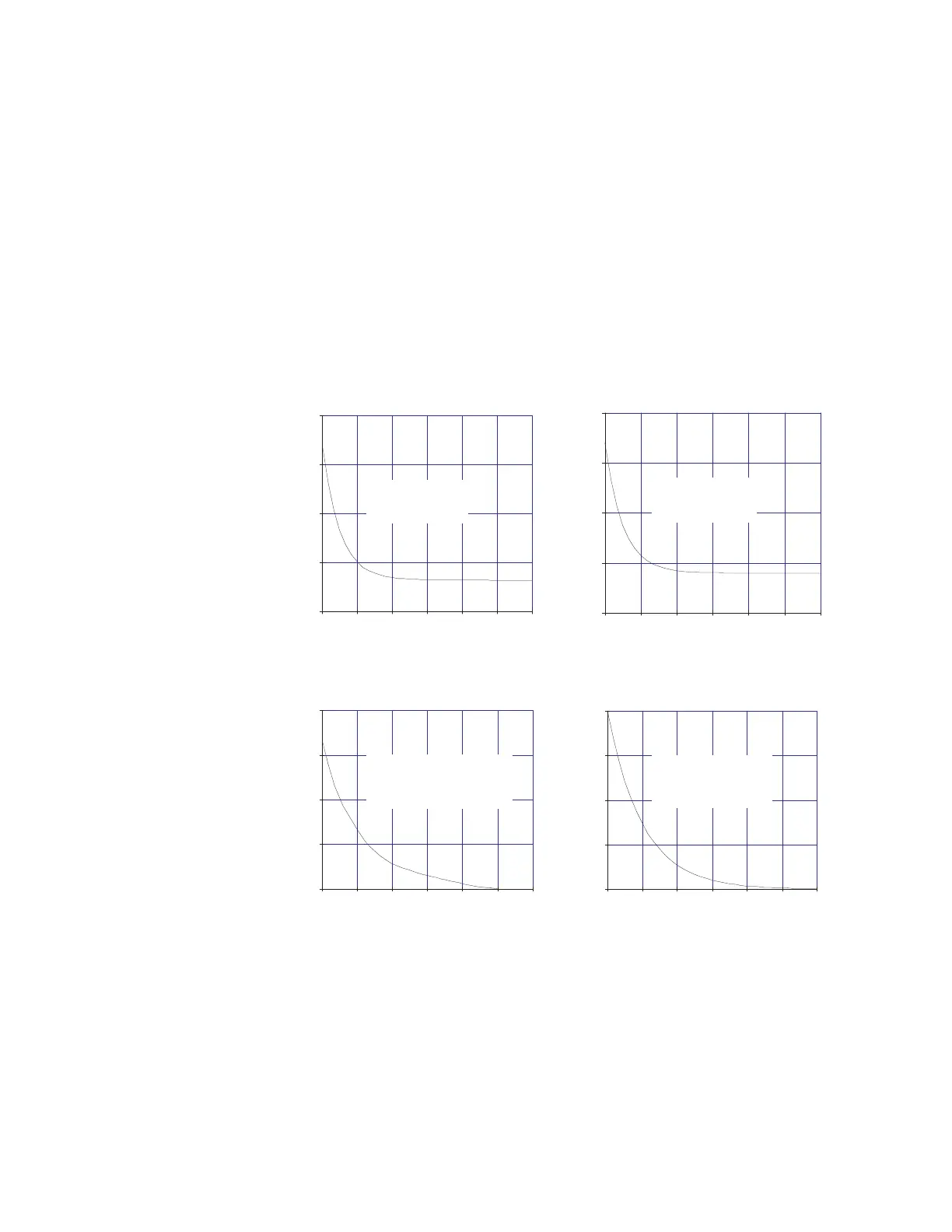

FIGURE 5–15: Thermal Model Cooling

Hot/Cold Safe Stall Ratio

The motor manufacturer may provide thermal limit information for a hot/cold motor. The

469 thermal model adapts for these conditions if the

HOT/COLD SAFE STALL RATIO settings

is programmed. This settings value dictates the level of thermal capacity used the relay will

settle at for current levels below the

OVERLOAD PICKUP LEVEL. When the motor is running

TC

used

TC

used_start

TC

used_end

–()e

t τ⁄–

()TC

used_end

+=

TC

used_end

I

eq

ol_pkp

----------------

⎝⎠

⎛⎞

1

hot

cold

----------–

⎝⎠

⎛⎞

100%×=

808705A2.CDR

0

25

50

75

100

0 30 60 90 120 150 180

Time in Minutes

Thermal Capacity Used

Cool Time Constant=15min

TCused_start=85%

Hot/Cold Ratio=80%

Ieq/Overload Pickup= 100%

0

25

50

75

100

0306090 120 150 180

Time in Minutes

Thermal Capacity U sed

Cool Time Constant=15min

TCused_start=85%

Hot/Cold Ratio=80%

Ieq/Overload Pickup=80%

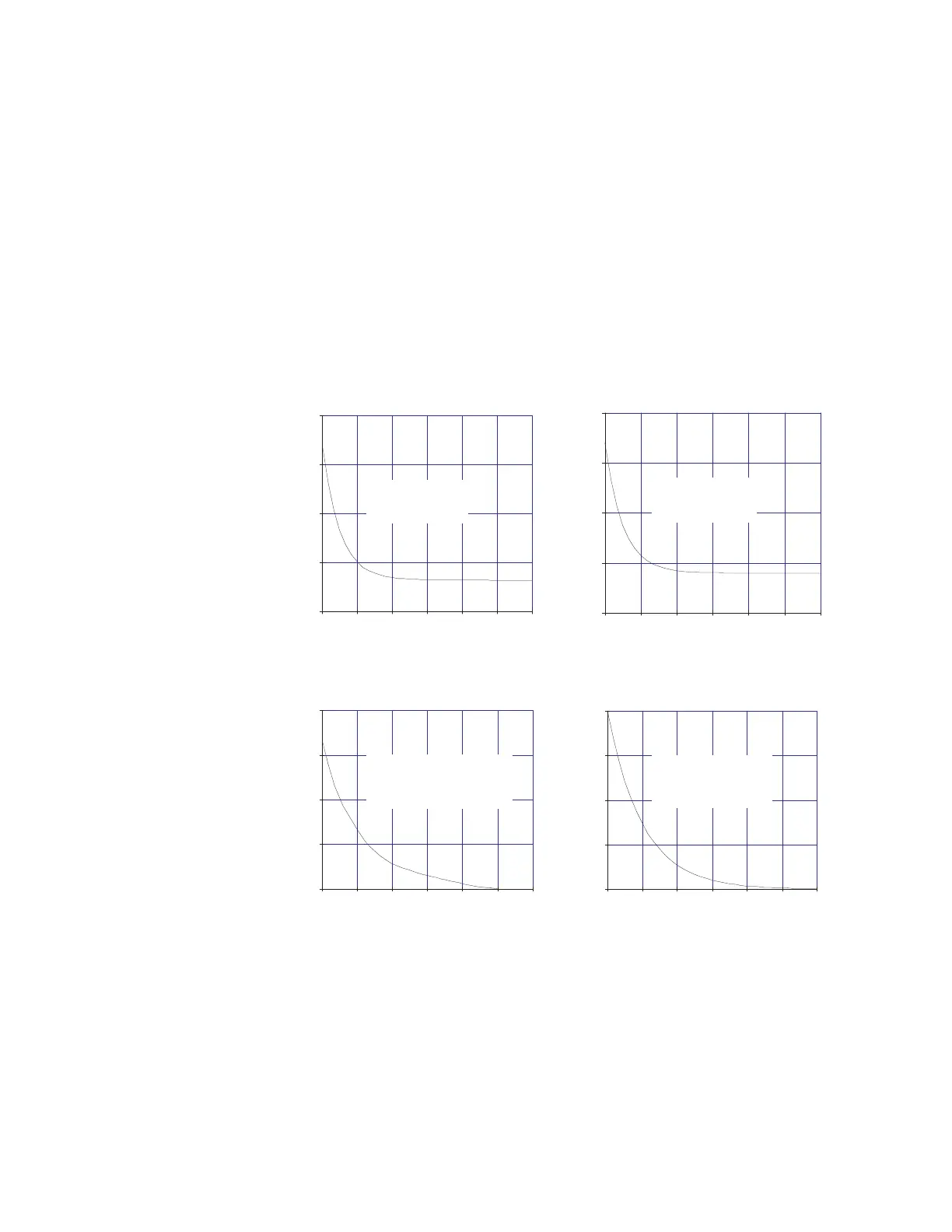

0

25

50

75

100

0306090 120 150 180

Time in Minutes

Thermal Capacity Used

Cool Time Constant=30min

TCused_start=85%

Hot/Cold Ratio=80%

Motor Stopped after running Rated Load

TCused_end=0%

0

25

50

75

100

0306090 120 150 180

Time in Minutes

Thermal Capacity Used

Cool Time Constant=30min

TCused_start= 100%

Hot/Cold Ratio=80%

Motor Overload

TCused_end=0%

MOTOR TRIPPED

100% LOAD

MOTOR STOPPED

80% LOAD

Loading...

Loading...