GEK-7303 Low Voltage

Power

Circuit

Breakers

reduction unit and through a worm

gear

and a

planetary

g~ar

train

drives

the

crank

(10, Fig. 10)

with a reduction 1000:1. To remove the

motor

and gear-reduction unit, _

proceed

as

follows:

1 • . Remove the

front

frame

(see

SEPARATION

OF FRONT

AND

R~AR FRAME.)

2.

.Remove closing

springs

and

crank-shaft

as

illustrate~ iii Fig.-

12

and 13.

3. Disconnect the

leads

from

motor and remove

the -wires attached to

gear

unit housing.

4.

Remove four bolts

at

the bottom of the

front

frame

and one

bolt

at

top of

gear

reduction

unit. The.

motor

and

gear

unit may

n!JW

be removed .•

NOTE

:

If

it

is

desired

to

replace

only the

motor unit, disconnect the

motor

. leads - and

remove only the hardware fastening

it

to the

. - -gear-reduction unit. When removing the motor

· only, the front

frame

should be placed

front

· side

down

to prevenJ. the oil escaping from the

. ·

gear

unit. ·

The

gear

. reduction

unit

contains 4 ounces of

oil

similar

to Atlantic Refining Company's Grade

HFS

No.

3.

·n

should not be

necessary

to add

or

· change oil except when the gear'.'.'reduction

unit-and

motor

are

disassembled • . - ·

QUICK

CLOSE

BREAKER

· .

ADJUSTMENTS

.

The quick close

breaker

basically differs

from

the standard

breaker

in

that

~e

p~echarging

_ operati<;m

is

extended

to

and slightly

past

the top

dead-

center

position of the closing

spring

assembly.

As

_.!tie

springs

start

. to discharge~ to close the

bre_aker, the discharge operation

is

arrested

by

~

pi:ap

and latch arrangement. The subsequent

closing operation

is

accomplished · by tripping

the

-latch to

release

the

prop

which in

turn

allows

the springs

to

continue the interrupted discharging

operation and close the

breaker.

The

gear

reduction unit

for

the

standard

breaker

is

· not interchangeable with the

gear

reduction

uniLon the quick

close

unit because the quick

close

gear

reduction unit employs a

slip

clutch

to relieve the

pressure

that would otherwise

be

. exerted between the output

crank

plate and

the prop. . ·

After the· closing springs have been completely

charged and the prop and latch

system

are

pre-

venting

closure

of

the

breaker,

the closing

opera-

tion may

be

.accomplished by energizing the closing

relay.

thni

the control relay contacts,

or

man-

ually- by

depressing

the push to

close

lever

which

mechanically displaces the latch to allow the

break~r to

close.

· .

. . .

On

drawout

breakers

an interlock between the ··

breaker and enclosure

requires

the springs

to

be

discharged before the

breaker

can be removed

from the

enclosure.

16

.

.'

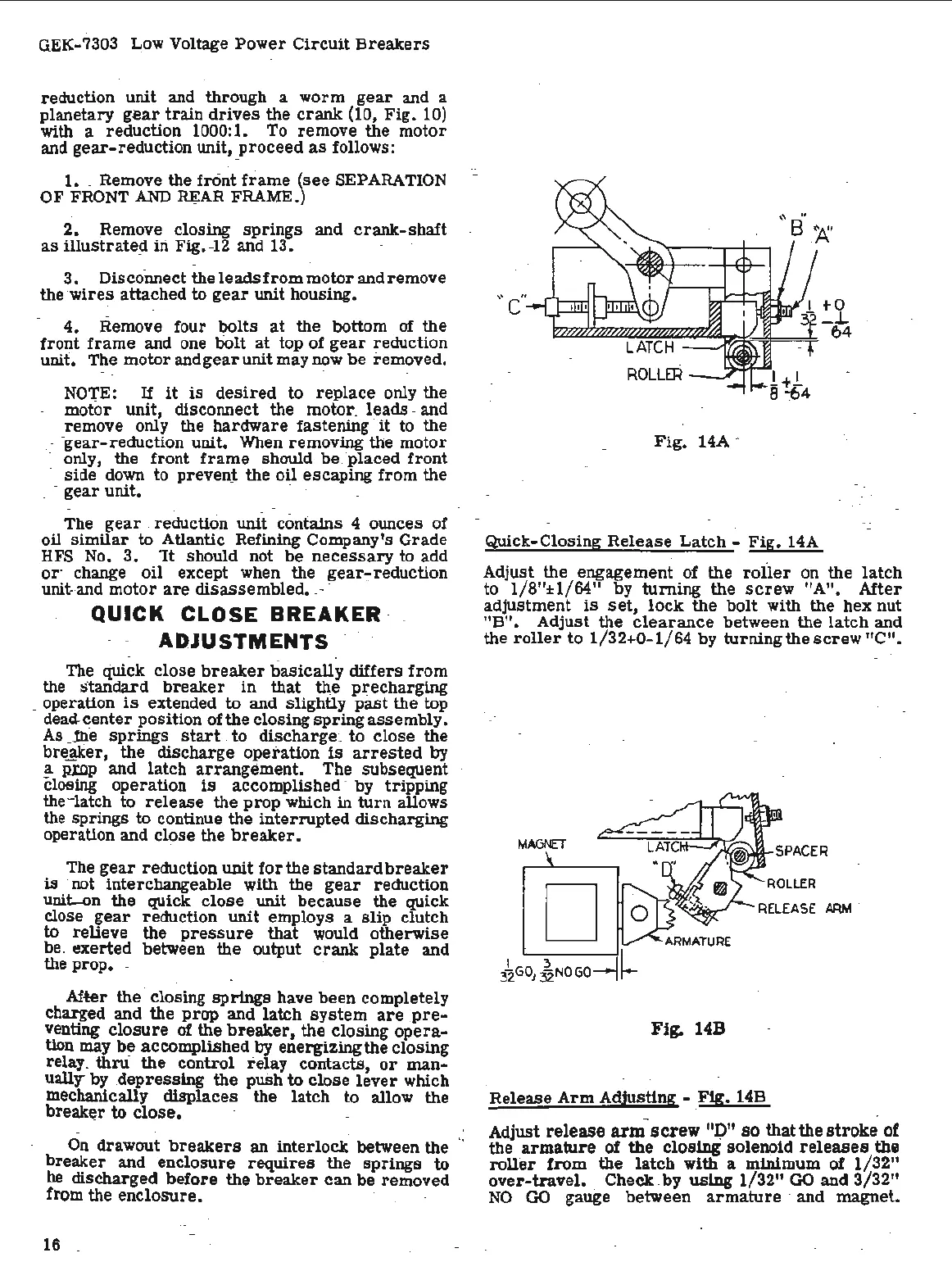

'c"

Fig

. 14A ·

Quick-Closing

Release

Latch

-

Fig.

14A

Adjust the engagement of the

roiler

on the

latch

to 1/8

11

±1/64" by

turning

the

screw

"A".

After

adjustment

is

set,

lock

the

bolt

with the hex nut

"B". Adjust the

clearance

between the

latch

and

the

roller

to

1/32+0-1/64

by

turning

the

screw

"C".

D

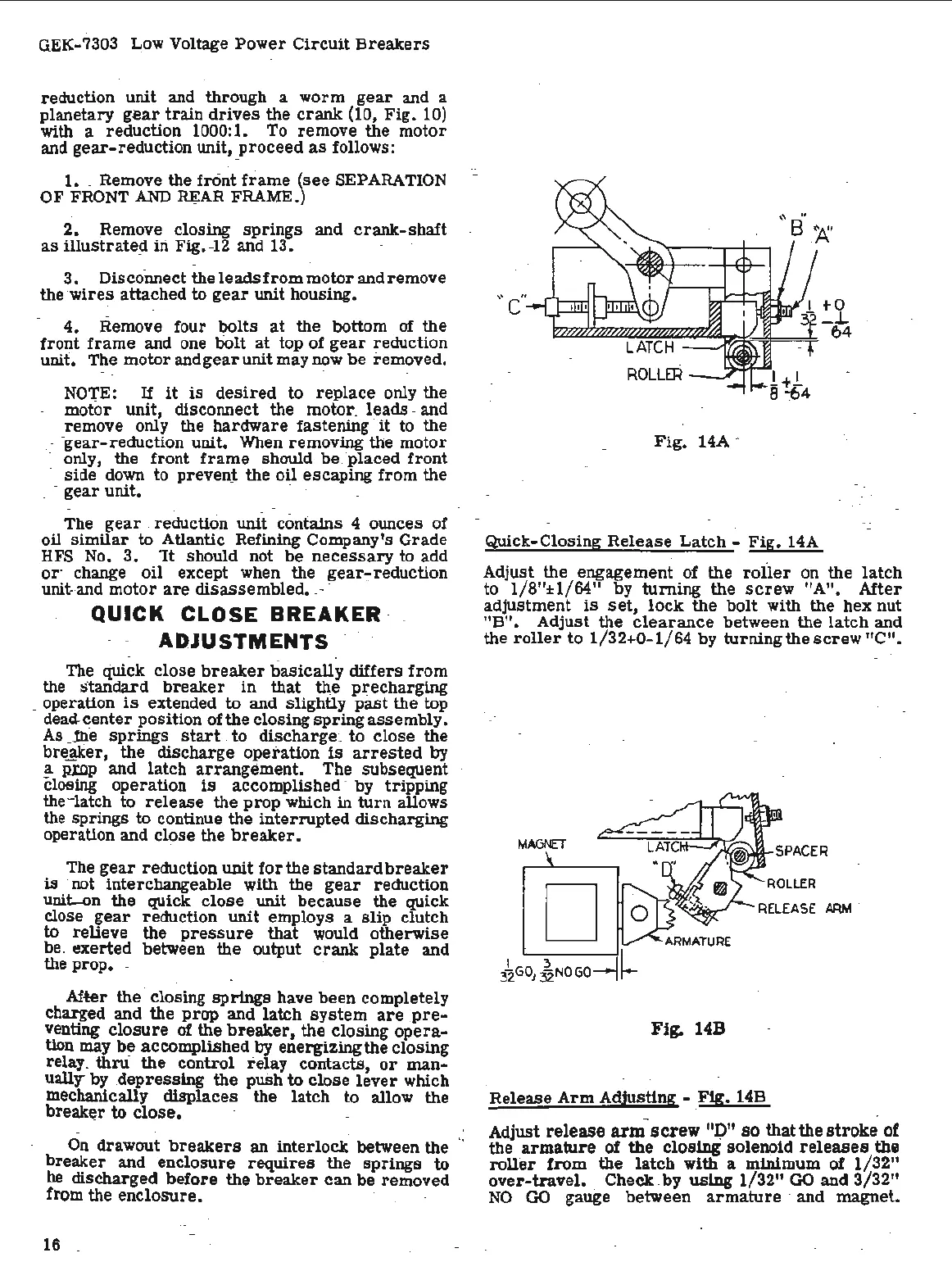

Fig. 14B

Release Arm Adjusting -

Fig.

l4B

Adjust release arm screw

"P"

so that

the

stroke of

the

armature

of the closing

solen<:>id

releases

the

roller

from

the

latch

with a minimum

of

1/32"

over-travel.

·Check. by

using

1/32"

GO

and

3/32"

NO

·

GO

gauge between

armature

· and magnet.

Loading...

Loading...