GEK-7303 Low Voltage

Power

Circuit

.

Breakers

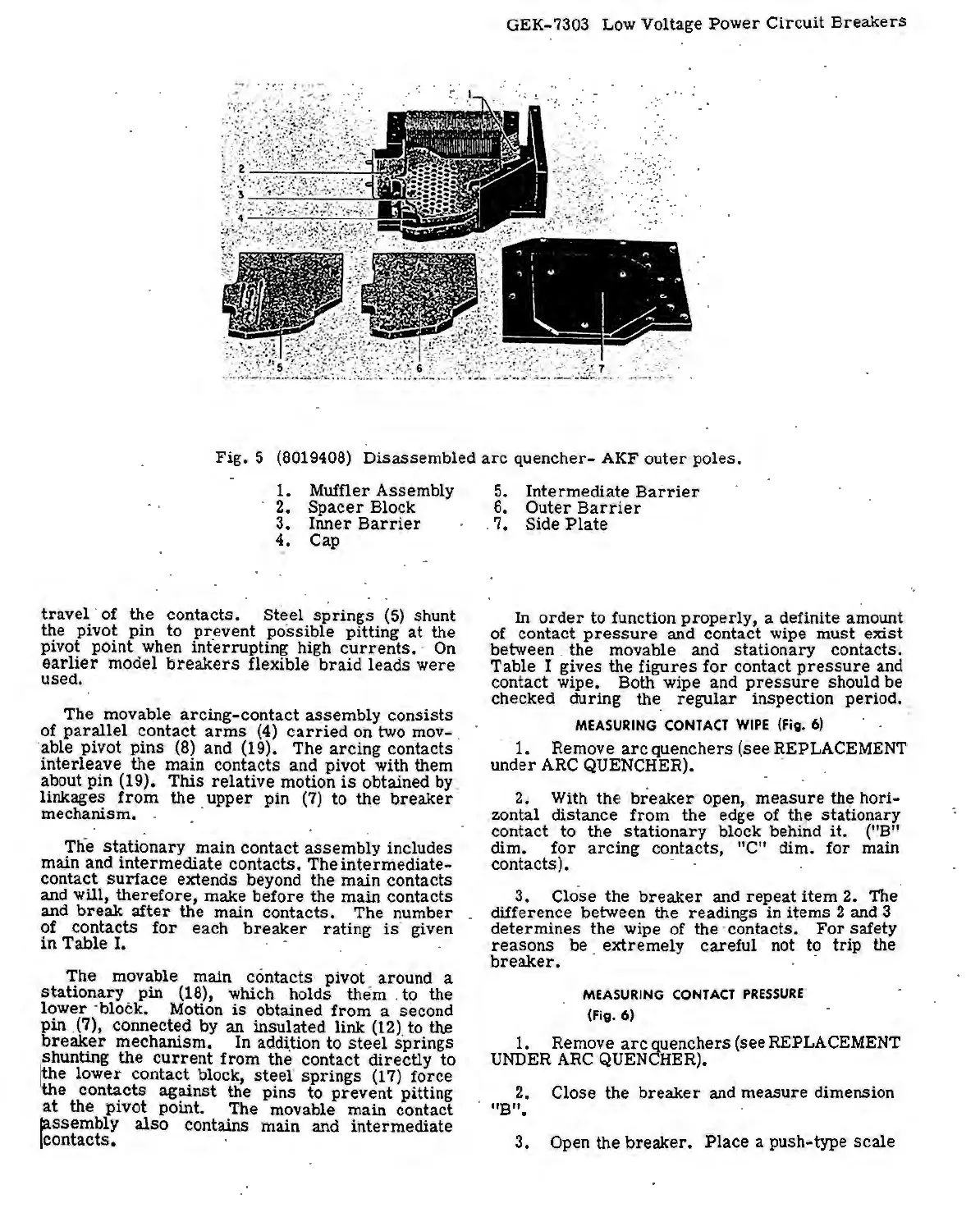

Fig.

5 (8019408) Disassembled

arc

quencher- AKF

outer

poles.

1. Muffler Assembly

2.

Spacer

Block

3.

Inner

Barrier

4. Cap

travel

· of · the

contacts.

Steel

springs

(5)

shunt

the pivot pin to

pr

_event possible pitting

at

the

pivot point when interrupting high

currents.

·

On

earlier

model

breakers

flexible

braid

leads

were

used.

rhe

movable ~rcing-contact a~sembly consists

of

parallel

contact

arms

(4)

carried

on two mov-

·able pivot

pins

(8)

and (19). The

arcing

con.tacts

interleave the main · contacts and pivot with them

about pin (19).

This

relative

motion

is

obtained by.

linkages

from

the

upper

pin

(7)

to the

breaker

mechanism. . . ·

Th·e

stationary

main contact

assembly

includes

main and

intermediate

contacts. The

intermediate-

contact

surface

extends beyond the main contacts

and will,

therefore,

make

before

the main contacts

and

break

after

the main contacts. The number

of contacts

for

each

breaker

rating

is

· given

in

Table

I.

The movable main contacts pivof around a

stationary

pin (18), which holds

them

. to the

lower

·block. Motion

is

obtained

from

a second

pin

.(7), connected by an insulated

link

(12). to tl\e

breaker

mechanism.

In

addition to

ste

·

e1

springs

shunting

the

current

from the contact ·

directly

to

!the

lower

contact block,

steer

springs

(17)

force

liiie

con~cts

ag~nst

the pins to prevent pitting

at

the

pivot

pomt. The movable main contact

jassembly

also

contains main and intermediate

!contacts.

5. Intermediate

Barrier

6.

Outer

Barrier

. 7. Side

Plate

In

order

to function

properly,

a definite amount

of contact

pressure

and contact wipe must

exist

between . the movable and

stationary

contacts.

Table I gives the

figures

for

contact

pressure

and

contact wipe. Both wipe and

pressure

should be

cpecked during the_

regular

inspection period.

-:

MEASURING

CONTACT

WIPE

(fig. 6)

· 1. Remove

arc

quenchers

(see

REPLACEMENT

under

ARC

QUENCHER). .

2. With the

breaker

open,

measure

the hori-

zontal distance

from

. the edge of the stationary

contact to the

stationary

block behind

it.

('.'B"

dim.

for

arcing

contacts, "C" dim.

for

.main

contacts). ·

3. Clo.

se

the

breaker

and repeat

item

2. The

difference between the readings in items 2 and 3

determines

the wipe of the · contacts.

For

safety

reasons

be extremely careful not to trip the

breaker.

· . ·

MEASURING

CONTACT

PRESSURE

(Fig.

6)

1. Remove

arc

quenchers (see REPLACEMENT

UNDER

ARC

QUENCHER).

2. Close the

breaker

and measure dimension

"B".

3.

Open the breaker.

Place

a push-type

scale

Loading...

Loading...