EL

ECTR

IC

AL TRIPPING

-

The

breaker

may

be

tripped

electrically

by any

of tha

electrical

tripping devices

described

in

these

instructions.

. The

breaker

may also

be

tripped

by the automatic

overcurrent

or

reverse

current

tripping devices, if

so

equipped. All

these

devices

trip

the

breaker

inasimilarmanner,

i.e.

·the device

trip

arm

moves

against

the

trip

paddles

fastened on the

trip

shaft

, thus rotating

the

trip

shaft

and displacing the

trip

latch.

The

most

commonly

used

tripping device

is

the

shunt

trip

device connected in the control

circuit

as

shown

in

Fig.

1.

When a tripping

signal

is

given,

the shunt

trip

coil

is

energized through a nortrlally-

open auxiliary switch "

a"

-contact, thus tripping

· tbe

breaker.

. .

MAINTENANCE

BEFORE INSPECTION OR

ANY

MAINTENANCE

WORK

IS

DONE

BE

SURE THAT THE BREAKER

IS

IN THE OPEN POSITION. ALL ELECTRICAL

POWER, BOTH PRIMARY

AND

· CONTROL

SOURCES, SHOULD

ALSO

BE DISCONNECTED.

Warning: On

breakers

employing

stored-en-

ergy

closing mechanisms,

care

must

be

taken

when the

circuit

breaker

is

being

installed

and when any inspection

or

maintenance work

is

being done

so

that

the

breaker

is

in

the

open·

position

and the closing

springs

are

· being re15trained by

the

safety pin. The

proce-

dure

for

inserting

the safety pin

is

given below.

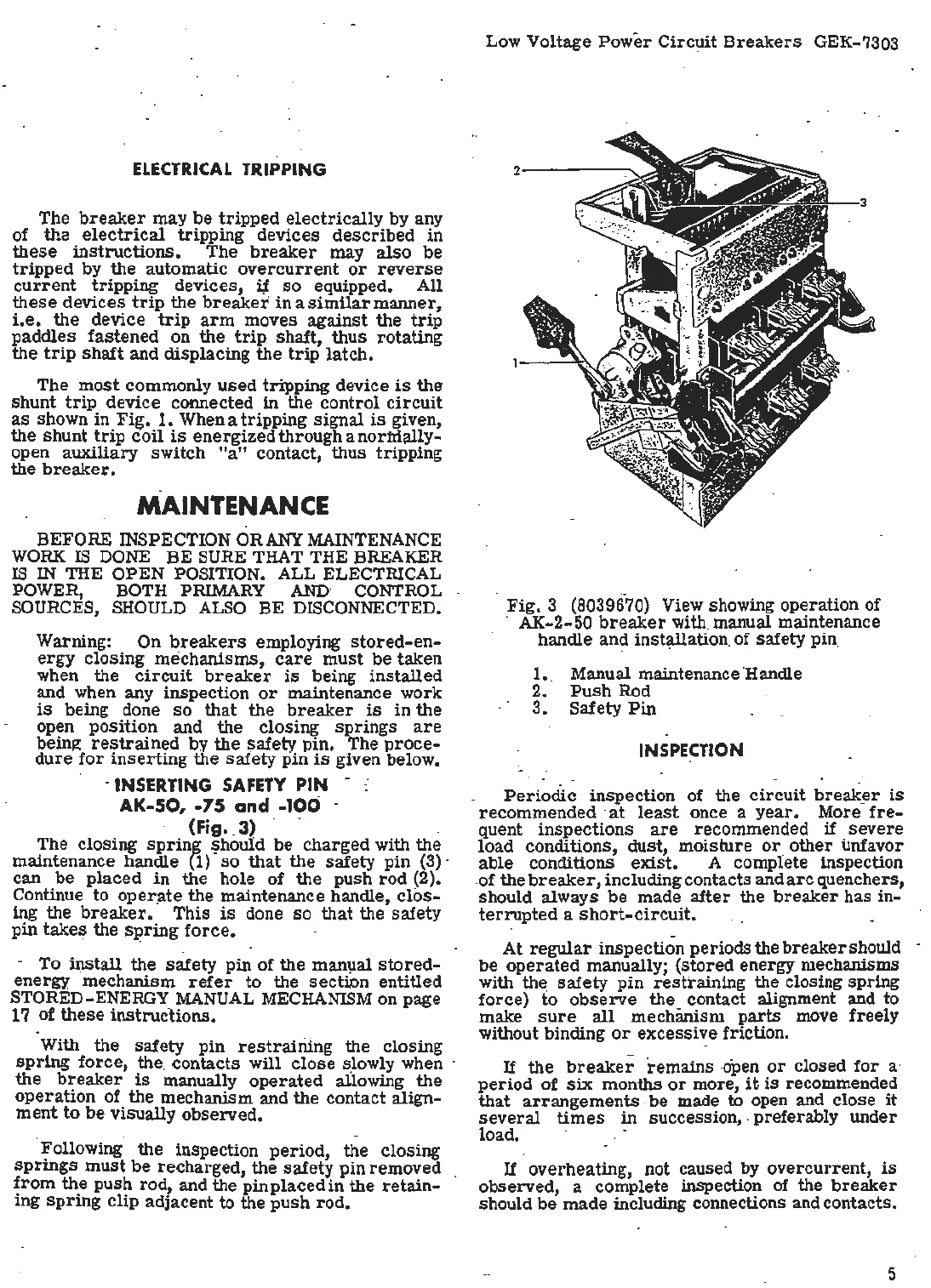

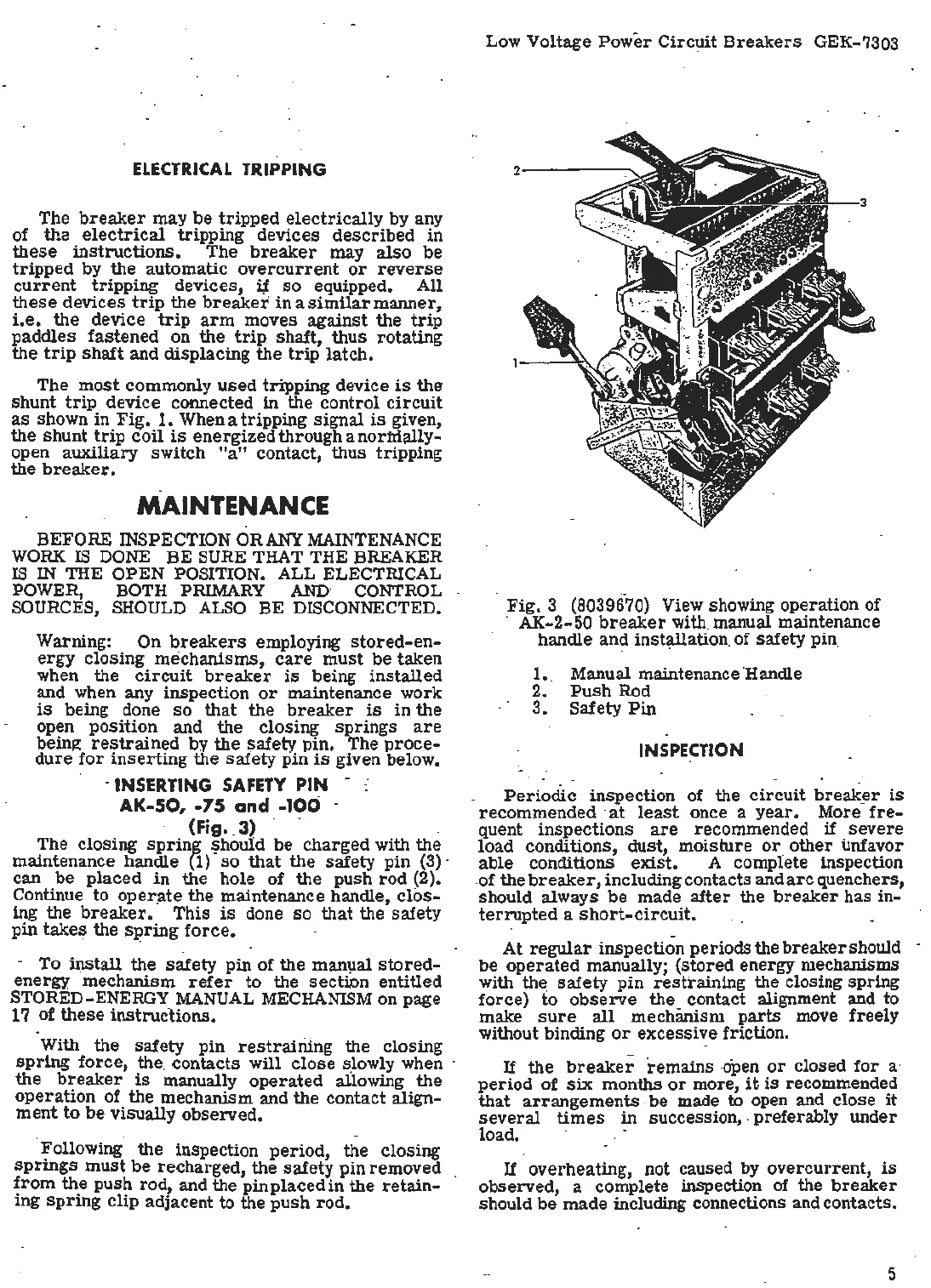

- INSERTING

SAFE

TY

PIN

-

AK

-5

0, -

75

and

-100

·

. (Fig

•.

3)

. .

The closing

sprini

~hould be charged with the

maintenance handle

(1)

so

that

the safety pin

(3)

-

can be

placed

in

the hole of the push

rod

(2).

Continue to op

er

.

ate

the maintenance· handle,

clos-

ing the

breaker.

This

is

done

so

that

the safety

pin

takes

the SJ?ring

force

.

- To il)stall the

safety

pin of the manµal

stored

-

energy mechanism

refer

to the

section

entitled

STORED- ENERGY MANUAL MECHANISM on page

17

of

these

instrucUons.

With the safety pin

restraining

the closing

spring

force, the. contacts will

close

s.lowly when ·

the

breaker

is

manually

operated

a1lowing the

operation

of the mechanism and the contact align-

ment

~o

be

visually observed.

. . -

.

!allowing

the inspection

period,

the closing

sprmgs

must be recharged, the

safety

pin

removed

from

the

push

rod, and the pin placed

in

the

retain-

ing

spring

clip adjacent to the push

rod.

Low Voltage

Power

Circ~it

Breakers

GEK-7303

Fig. 3 {8039670) View showing operation of

· AK-2-50 ·

breaker

with manual maintenance

handle and installation. of safety pin,

1.. Manual maintenance 'Handle

2.

Push

Rod

3.

Safety

Pin

INSPECTI

ON

Periodic

inspection of the

circuit

break~r

is

recommended ·

at

least

once a

year.

· More

fre-

quent inspections

are

recommended

if

severe

load. conditions, dust, moisture

or

_

other

unfavor

able conditions

exist.

A complete inspection

.of the

breaker,

including contacts and

arc

quenchers,

should always

be

made

after

the

breaker

has in-

terrupted

a

short-circuit.

At

regular

inspection periods the

breaker

should -

be

operated

manually; (stored energy mechanisms ·

with the

safety

pin

restraining the closing spring

force)

fo

observe

the contact alignment and to

make

sure

all

mechanism

parts

move freely

without binding

or

excessive friction.

If

the

breaker

remains

-open

or

closed

for

a·

period

of

six

months

or

more,

it

is

recommended

that

arrangements

.

be

made to open and close

it

several

times

in succession, . preferably under.

load.

If overheating, not caused by overcurrent,

is

observed, a complete inspection

of

the

breaker

should

be

made including connections and contacts.

5

Loading...

Loading...