5.

Push

wire

through hollow tube of new

di$connect

assembly.

.

6~

Strip

in&ulation off end of

wire

to about

1/4

in.

from

the

end.

7.

Place

new contact tip on end of

wire

and

crimp.

8.

Pull

wire

through hollow tube

until

contact

tip

fits

snugly

against

· end of hollow tube.

9.

Crimp

tab

on

other

side

of

assembly

to

hold

wire

in

place.

10.

Any hollow

tubes

which

are

not

used

should

be

pushed

into

the

disconnect body and held

in

that

position

by

.

placing

fiber

spacer

s

over

inner

ends

of

tubes

and

spreading

tabs.

11.

When

all

wires

have

been

connected,

refasten

the

body

of

the

movable disconnect

assembly

to the

breaker

cross-channel.

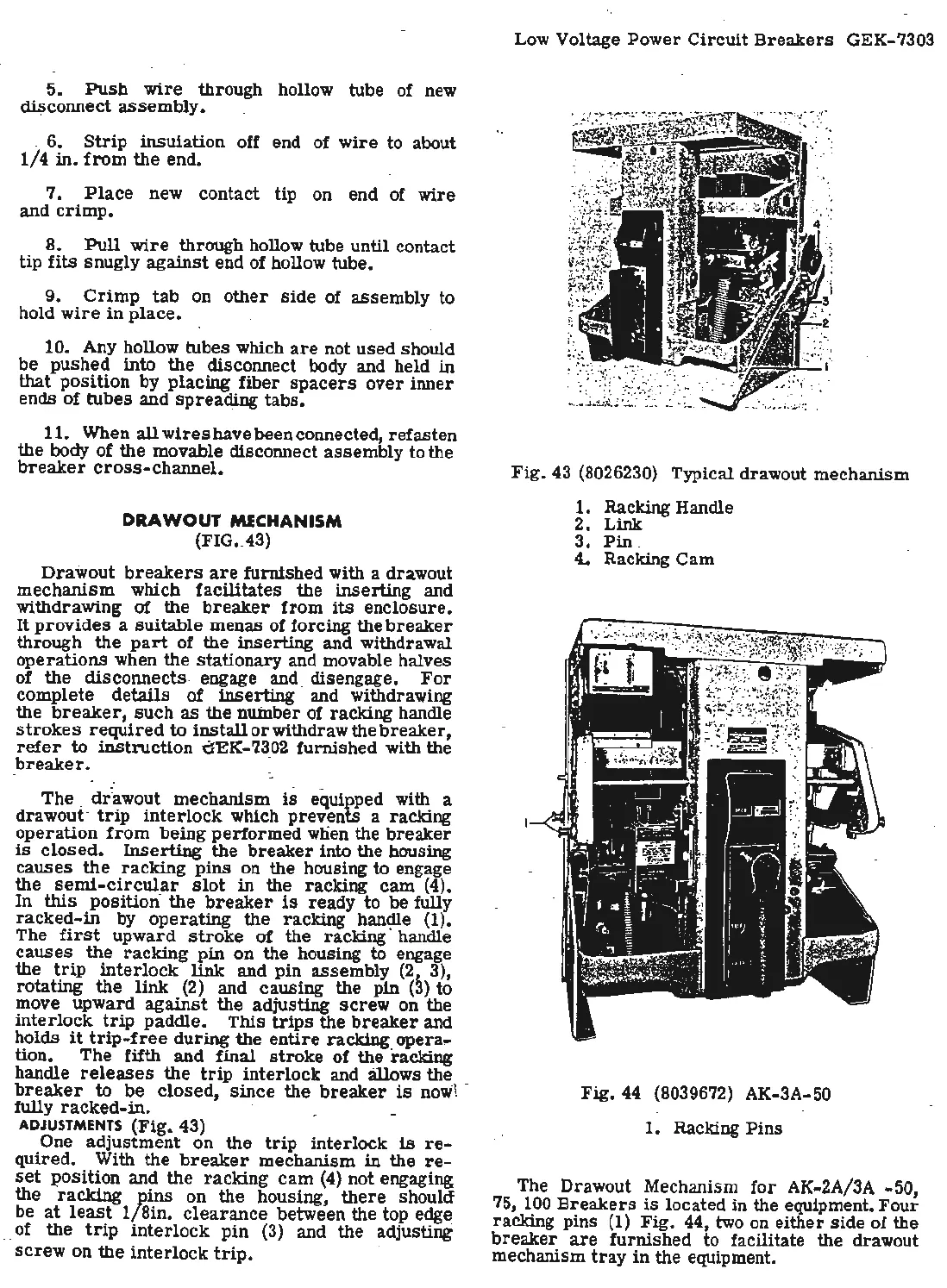

· DRAWOUT

MECHANISM

.

(FIG •. 43)

Drawout

breakers

are

furnished with a drawout

mechanism

which

facilitates

the

inserting

and

withdrawing

of

the

breaker

from

its

enc

losure.

It

provides

a

suitable

menas

of

forcing

the

breaker

through

the

part

of

the

inserting

and withdrawal ·

operations

when

the

stationary

and movable halves

of

the

disconnects

. engage and_ disengage.

For

complete

details

of

inserting

and withdrawing

the

breaker,

such

as

the nuinber of racking handle

strokes

required

to

install

or

withdraw

the

breaker,

refer

to

instruction

ezEK-'Z302 furnished with the

breaker.

·

The

. ctr·awout

mechanism

is

·equipped with a

drawout

· t

rip

interlock

which

prevents

a racking

operation

from

being

performed

wlien the

breaker

is

closed.

Ins

erting

the

breaker

into

the

housing.

causes

the

racking

·

pins

.

on

the

housing

to

engage

the

semi

-

circular

slot

in

the

racking c~m (4).

In

this

position

the

breaker

is

ready

to

be

fully

racked-in

by

operating

the

racking handle (1).

The

·

first

upward

stroke

of the racking· handle

causes

the

racking

pin

on

the housing to engage

the

trip

interlock

link

and pin

assembly

(2, 3),

rotating

the

link

(2) and causing the pin (3) to

move

upward

against

the adjusting ~crew on the

interlock

trip

paddle.

This

trips

the

breaker

-and

. holds

it

trip-free

during

the

entire

racking_

opera

..

tion.

The

fifth

and

.

final

stroke

of

the

racking

handle

releases

the

·

trip

interlock

and allows

the

_

breaker

to

be

closed,

.

since

the

breaker

is

now\

fully

racked-in

. .

ADJUSTMEN'J'.S

(Fig.

43)

One

adjustment

on

the

trip

interlock

is

re:.

quired.

With

the

breaker

mechanism

in

the

re-

set

.

position

and

the

racking

cam

(4)

not engaging

the ·

racking

~ins

on

the

housing,

there

should

be

at

least

1/8in.

clearance

between the top edge

..

of

the

trip

interlock

pin

(3) and the adjusting

screw

on

the

interlock

trip

.

Low Voltage

Power

Circuit

Breakers

GEK-7303

Fig

. 43 (8026230) Typical drawout me

chanism

1.

Racking Handle

2.

Link

. 3.

Pin

.

4..

Racking Cam

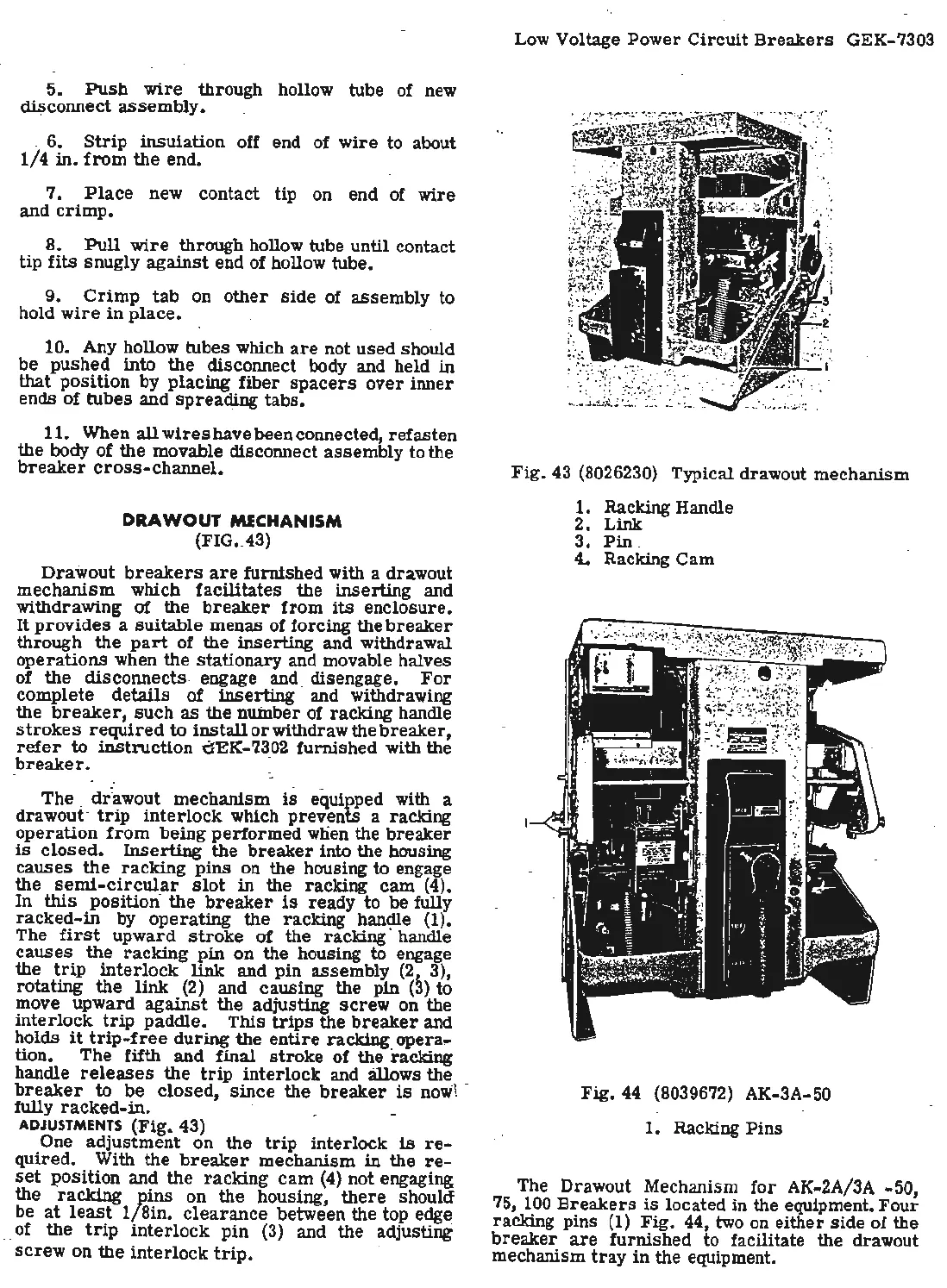

Fig.

44 (8039672) AK-3A-50

1.

Racking

Pins

The

Drawout Mechanism

for

AK-2A/3A -50,

75, 100

Breakers

is

located in the equipment.

Four

racking

pins

(1)

Fig.

44, two on

either

side

of

the

breaker

are

furnished

to facilitate the drawout

mechanism

tray

in

the equipment.

Loading...

Loading...