MA-003 – MULTITRANS User Guide – Rev 3.0 18-Jan-16 Page 23 of 30

1. If the product is in Standby mode, proceed to step 3. If the product is in

Measurement mode, manual sampling is prevented.

2. Press the red Stop button to stop the measurement process. The display reads

“OIL DRAINING”. If there is oil in the headspace, the draining process may take

several minutes. The product returns to Standby mode.

3. When the product is in Standby mode, remove the quick-connect body protector

by pulling the collar down.

4. Fit the male quick-connect fitting and valve assembly to the correct quick-connect

body on the base of the product as shown in Section 7.1. Ensure that the valve is

closed to prevent oil leakage.

5. Press the white Manual Sample button. The display reads “MANUAL DGA IN: 10s”.

Subsequent presses of the white button are used to toggle through and select the

required oil circuit to sample. Once a circuit name is displayed, the timer

automatically counts down from 10 seconds, and if the white button is not

pressed again, the displayed circuit is selected for manual sampling. Note: If the

product has to first switch oil circuits from the last measured circuit to the selected circuit, an “OIL

SWITCHING” notice displays.

6. An oil line purging process starts. The display reads “MANUAL DGA PURGING OIL

PRESS KEY WHEN DONE”.

To ensure accurate results, oil must be adequately purged before sampling

begins. This brings fresh oil from the transformer to the manual oil sampling port.

Typically this means waiting approximately 5–10 minutes, but the recommended

wait time can vary depending on the installation (longer tubing and lower

temperatures can increase the purge duration). Consult with Technical Support.

7. Press the white Manual Sample button. The display reads “{oil circuit name}

MANUAL DGA TAKE OIL SAMPLE PRESS KEY WHEN DONE”. Note: This indicates that the

oil sampling process can begin.

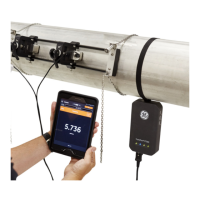

8. Remove the Luer fitting cap, connect the oil sampling equipment e.g. syringe, and

perform the oil sampling according to your standard process and procedures.

9. When finished sampling, close the valve and disconnect the oil sampling

equipment.

10. Remove the male fitting and valve assembly, and replace the body protector

fitting on the quick-connect body.

11. Press the white Manual Sample button to return the product to Standby mode.

Note: If left in Manual Sampling mode, the product reverts to Standby mode after one hour.

Measurement then begins at the next scheduled measurement time.

To start a measurement immediately, press the blue Start button and then select

the oil circuit to measure.

To take a manual sample from another oil circuit, press the white Manual Sample button

again. If a measurement has started since the previous sample, first press the red Stop

button.

See Section 6.1 for example notifications from the LCD panel.

Loading...

Loading...