17. Troubleshooting

2-99

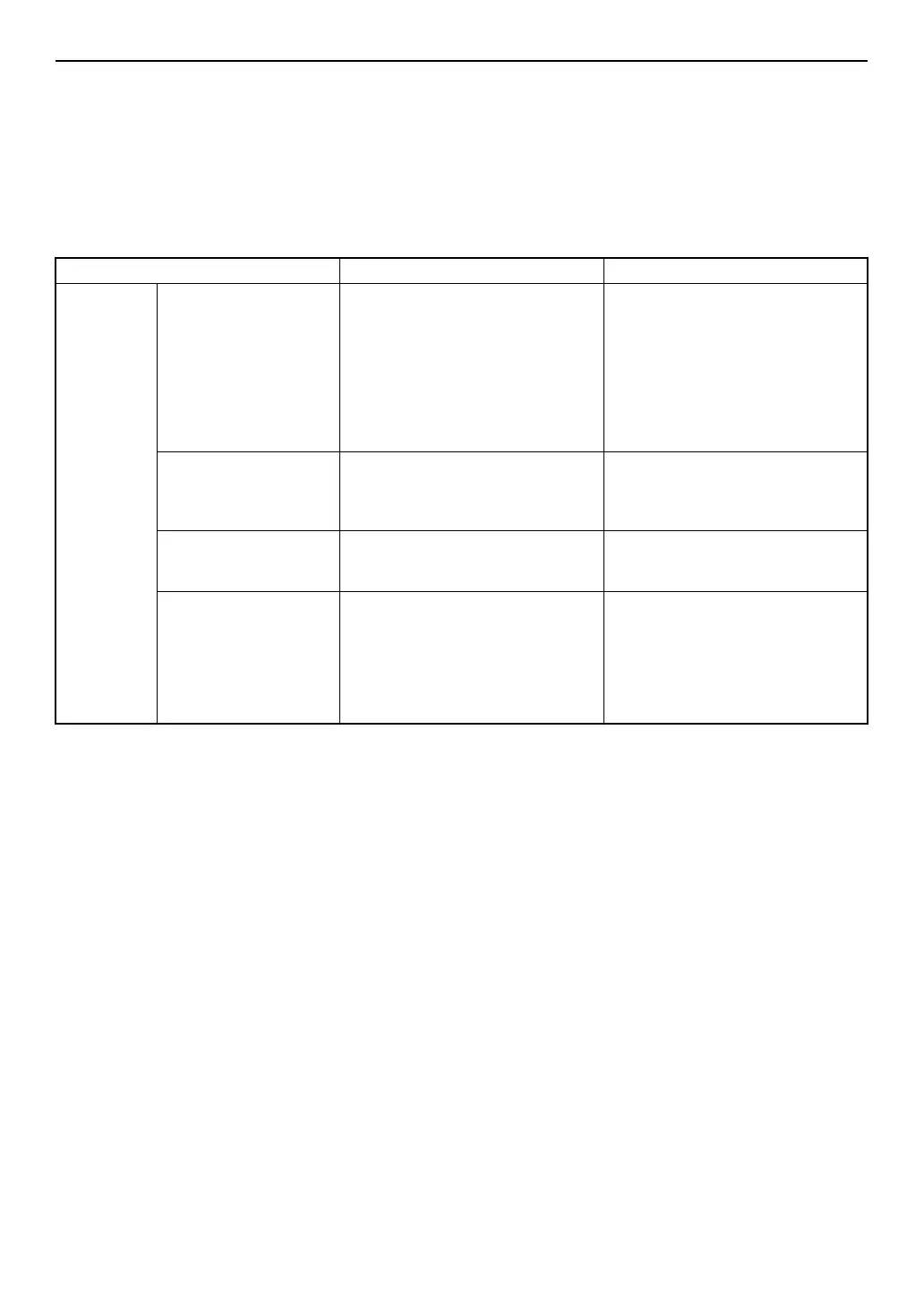

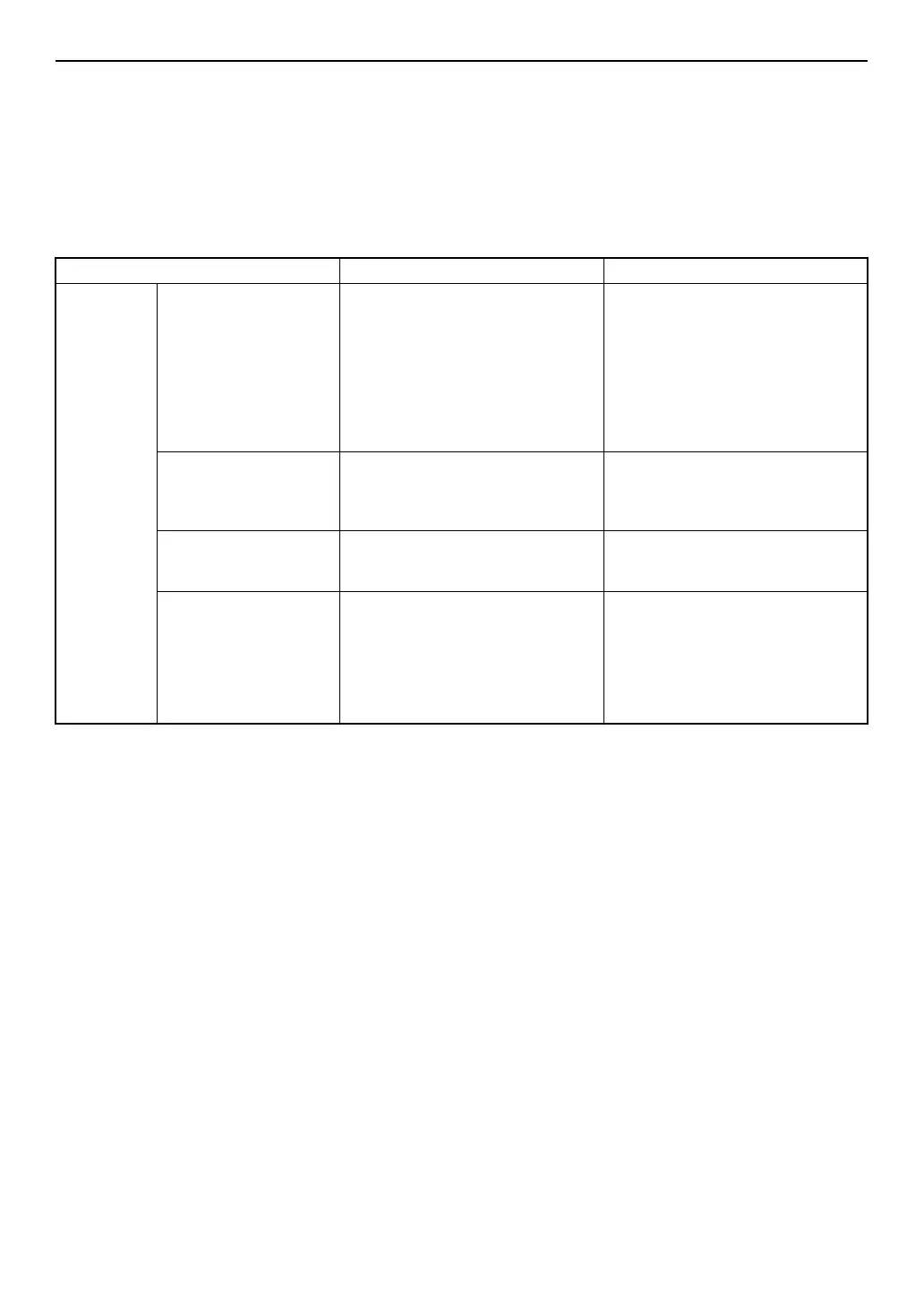

17-4-2. Machine performance

• Contact your dealer about the measures shown in pa-

rentheses in the list below.

• If there is any abnormality or trouble whose cause is un-

known other than those shown below, ask your dealer for

repair.

Problem Cause Measure

Machine

performance

Power or speed of moving

part is low.

• Deteriorated function caused by worn

hydraulic pump

• Pressures of main relief valve, or port

relief valve of control valve are

dropped below set value.

• Damaged hydraulic cylinder

• Insufficient amount of hydraulic oil

• Clogged filter

(• Replace hydraulic pump.)

(• Check and repair valves.)

(• Check and repair.)

• Replenish hydraulic oil up to specified

level.

• Clean or replace filter.

Upperstructure does not

swing or does not swing

smoothly.

• Swing brake is not released

• Insufficient amount of grease

• Defective swing brake valve

• Defective swing motor

(• Check and repair.)

• Check and grease.

(• Check and repair.)

(• Check and repair.)

Temperature of hydraulic

oil is too high.

• Insufficient amount of hydraulic oil

• Overload

• Replenish hydraulic oil up to specified

level.

• Lower load.

Machine does not move

straight.

• Improperly adjusted track or trapped

foreign material

• Damaged hydraulic motor.

• Defective hydraulic pump

• Defective control valve

• Damaged sprocket, idler or track roll-

er.

• Adjust or clean.

(• Check and repair.)

(• Check and repair.)

(• Check and repair.)

(• Check and repair.)

Loading...

Loading...