25. Procedures for Maintenance

3-60

Also perform the maintenance every 50, 100, 250 and 500 service hours.

25-8-1. Replacing the lube oil for the travel reduction gearbox

Things to prepare

• Container for waste oil : Capacity of 0.53 Qts. (0.5 L) or more

• New oil : 0.53 Qts. (0.5 L) for right and left each

• Oil jug : Capacity of 0.53 Qts. (0.5 L) or more

1)

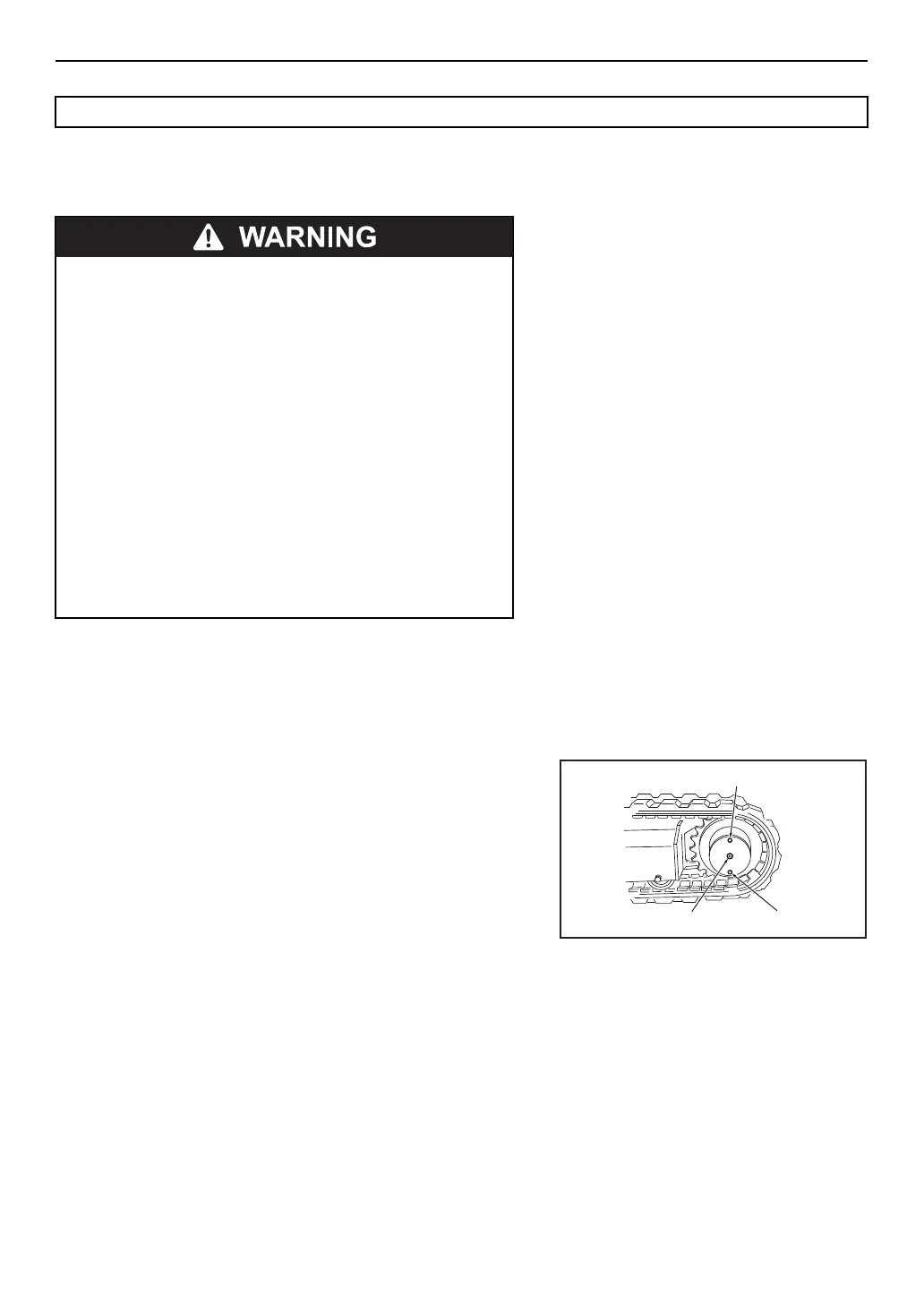

Align the three ports perpendicularly to the ground sur-

face. (See the right figure)

.

2) Put the container for the waste oil under the drain port.

3) Remove the drain port, and level port plugs with a hexa-

gon socket screw key to drain the waste oil.

4)

After draining the waste oil, install the plug to the drain

port.

[Tightening torque : 15.9 to 17.4 ft•lbf (21.6 to 23.5 N•m)]

5) Replenish gear oil to the specified level through the oil

supply port. Refer to Section "21. Fueling, Oiling and

Greasing Based on Temperature Range" for the oil to

be used.

6) When the oil overflows from the level port, reinstall the

oil supply port and level port plugs.

[Tightening torque : 15.9 to 17.4 ft•lbf (21.6 to 23.5 N•m)]

25-8. Maintenance every 1000 service hours

• The gear oil and casing of the reduction gearbox

are hot immediately after ceasing machine oper-

ation and can cause bodily injury such as a burn.

Do not allow hot oil or the gearbox to contact

your skin.

Replace the oil after the oil and the gearbox have

cooled enough to permit touching the surface of

the gearbox casing with your bare hand.

• At operating temperature, the reduction gearbox

is hot and its contents are under pressure.

In such condition, the oil or a plug may be eject-

ed violently, causing bodily injury. Loosen a plug

slowly to gradually relieve the residual pressure.

Oil supply port

Drain port

Oil level check port

009167-00E

Loading...

Loading...