PLACEMENT WITHIN THE SHOP /

ESTABLISHING A SAFETY ZONE

PLACEMENT WITHIN THE SHOP

This machine should be installed and operated

only on a solid, flat and stable floor that is able

to support the weight of the saw and the ope-

rator.

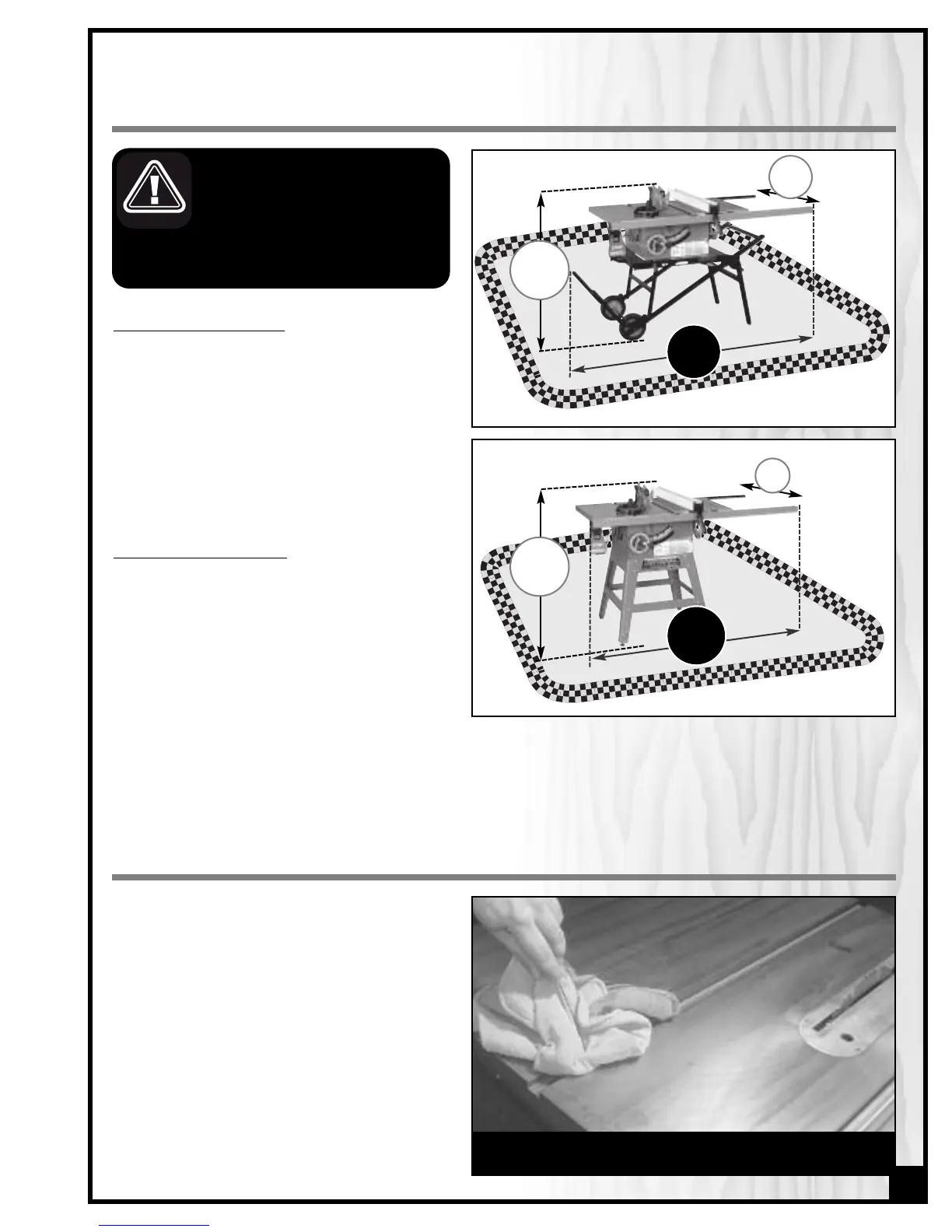

Using the dimensions shown as a guideline, plan

for placement within your shop that will allow

the operator to work unencumbered and unob-

structed by foot traffic (either passing shop visi-

tors or other shop workers) or other tools or ma-

chinery.

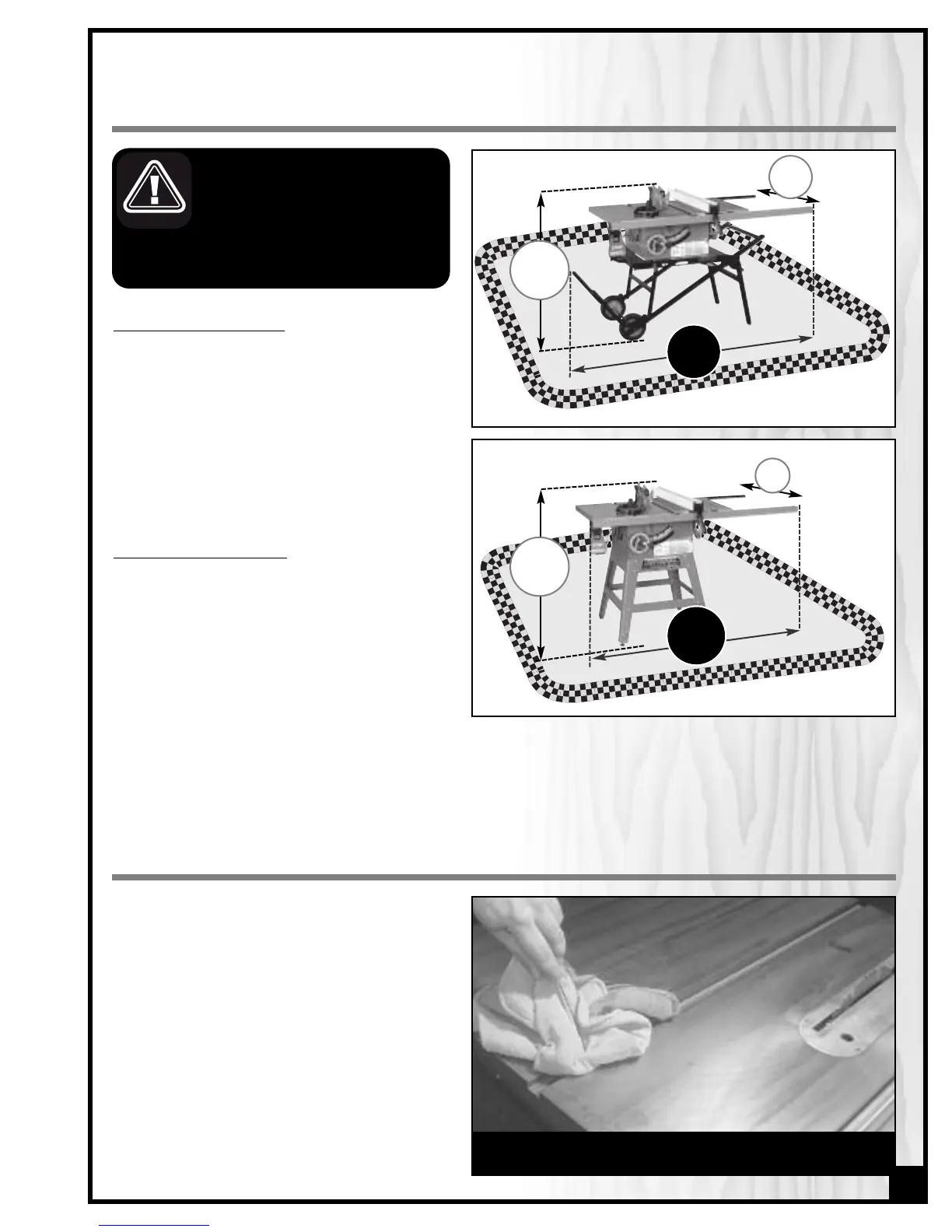

ESTABLISHING A SAFETY ZONE

For shops with frequent visitors or multiple oper-

ators, it is advisable to establish a safety zone

around shop machinery. A clearly defined “no-

go” zone on the floor around each machine can

help avoid accidents that could cause injury to

either the operator or the shop visitor. It is advis-

able to take a few moments to either paint

(using non-slip paint) or using tape, define on

the floor the limits or perimeter of each

machines safety zone. Take steps to ensure that all operators and shop visitors are aware that these areas are

off limits whenever a machine is running for everyone but the individual operating the unit.

THIS MODEL IS HEAVY. DO NOT OVER-EXERT.

A

HOIST OR FORKLIFT WITH STRAPS SHOULD

B

E USED TO LIFT THIS MACHINE.

T

O LIMIT THE RISK OF SERIOUS INJURY

OR DAMAGE TO THE MACHINE, ANY

EQUIPMENT USED TO LIFT THIS MACHINE

SHOULD HAVE A RATED CAPACITY IN EXCESS OF 233 LBS

(

106 KG) FOR 50-090RK & 217 LBS (98.5 KG) FOR

5

0-090RC.

The protective coating on the saw table prevents

rust from forming during shipping and storage.

Remove it by rubbing with a rag dipped in

kerosene, mineral spirits or paint thinner. (Dispose

of potentially flammable solvent-soaked rags

according to manufacturer’s safety recommen-

dations.)

A putty knife, held flat to avoid scratching the sur-

face, may also be used to scrape off the coating

followed by clean-up with solvent. Avoid rubbing

the saw’s painted surfaces, as many solvent-

based products will remove paint.

To prevent rust, apply a light coating of paste wax

or use regular applications of any after-market

surface protectant or rust inhibitor.

Tip: With a screw driver, push a solvent-saturated rag into the T-

slots to remove the grease.

38”

69”

42 ½”

50-090RK M1

38”

66 ½”

43 ½”

50-090RC M1

9

CLEAN UP

Loading...

Loading...