SERVICE MANUAL ProSeal Classic/Plus/Premium

16

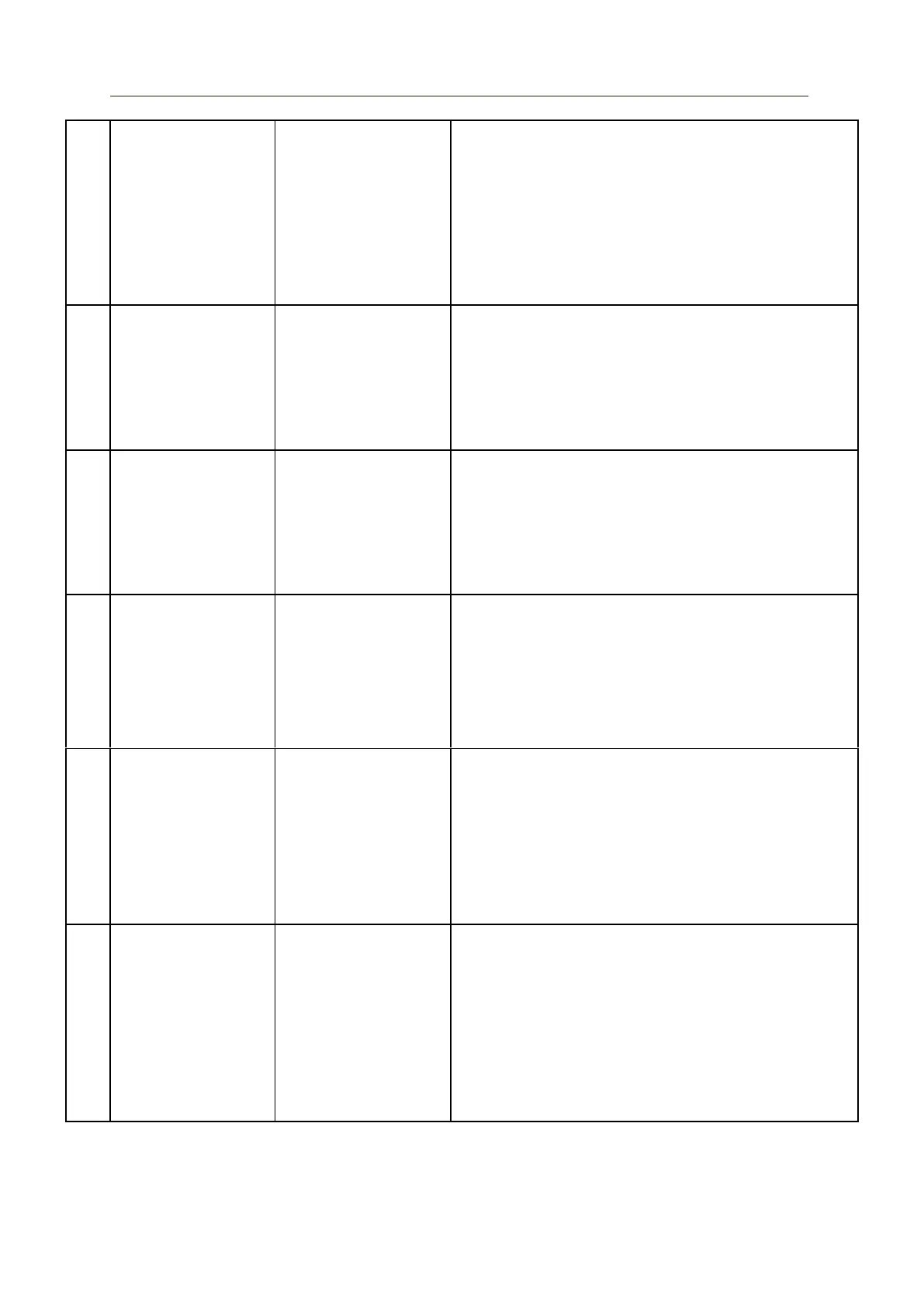

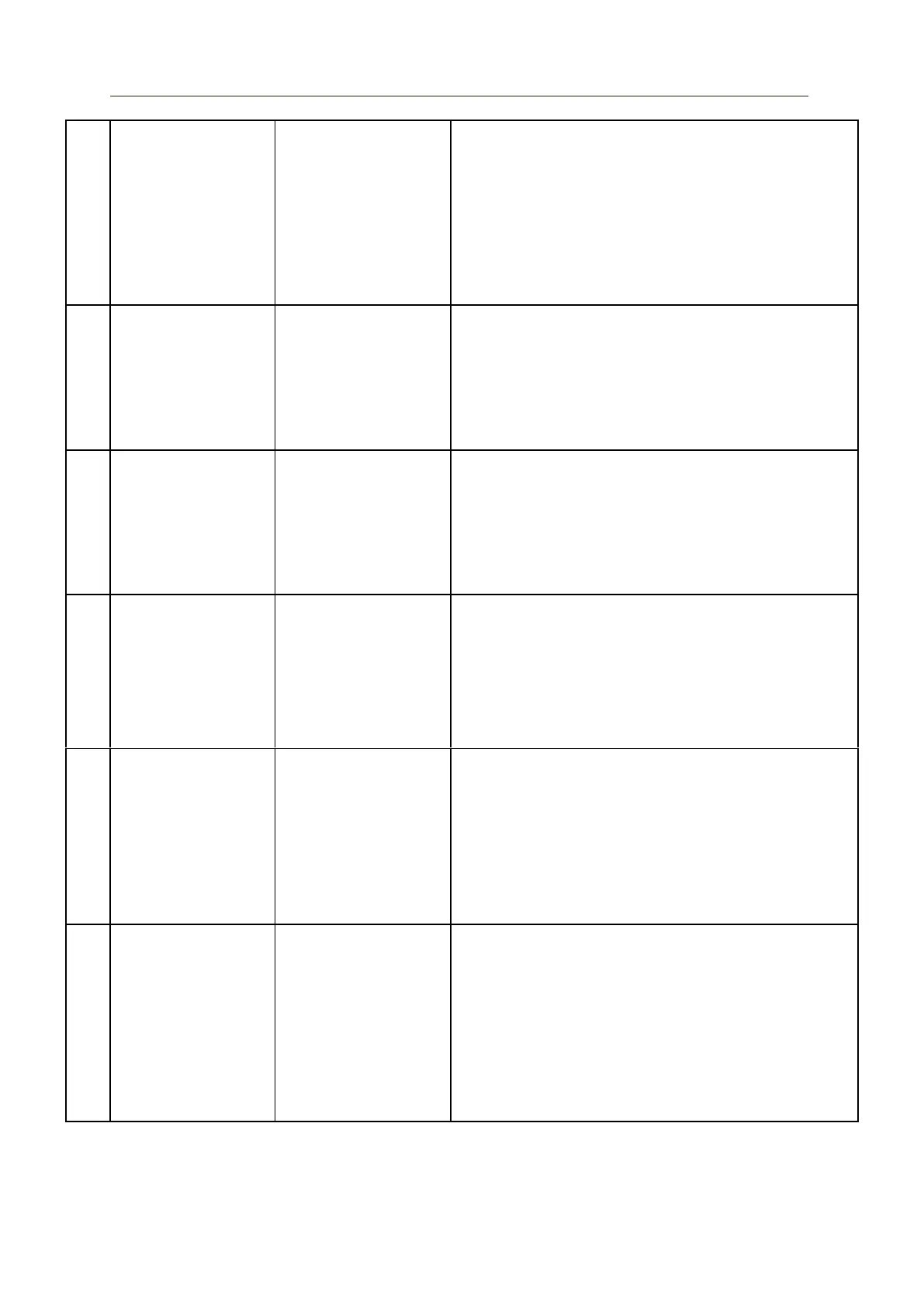

Could not print due

to pouch depth

Not able to print due

to pouch insertion

depth

Pouch not entered deep enough into the sealer.

The pouch doesn’t run over the printer head

PCB on the inlet of the pouch mounted

incorrectly

Check “sensors active” parameter by inserting

pouch

Cable start sensors disconnected / broken

Start sensor PCB defect

Control PCB defect

Temperature below

set point - alarm limit

Pouch detected before temperature was

reached

Alarm limit temperature too low

Cable temperature sensor disconnected /

broken

Temperature sensor on heating element defect

Control PCB defect

Temperature above

set point + alarm

limit

Pouch detected before temperature was

reached

Alarm limit temperature too low

Cable temperature sensor disconnected /

broken

Temperature sensor on heating element defect

Control PCB defect

Pressure below set

point - alarm limit

Set point pressure not correct

Alarm limit pressure too low

Pressure not correct (adjust the screw on the

pressure sensor according to paragraph 4.3.3)

Pressure wheel not clean

Pressure sensor defect

Control PCB defect

Pressure above set

point + alarm limit

Set point pressure not correct

Alarm limit pressure too low

Pressure not correct (adjust the screw on the

pressure sensor according to paragraph 4.3.3)

Pressure wheel not clean

Pressure sensor defect

Control PCB defect

Speed below set

point - alarm limit

Pouch too heavy or thick

Alarm limit speed too low

Belt too loose or too tight

PCB on the inlet of the pouch mounted

incorrectly

Encoder sticker on the belt pulley damaged

Cable start sensors disconnected / broken

Start sensor PCB defect

Control PCB defect

Loading...

Loading...