OPERATOR Book No.: 95-0014-0000/A

HANDBOOK Issue: 06

Page 10 of 30

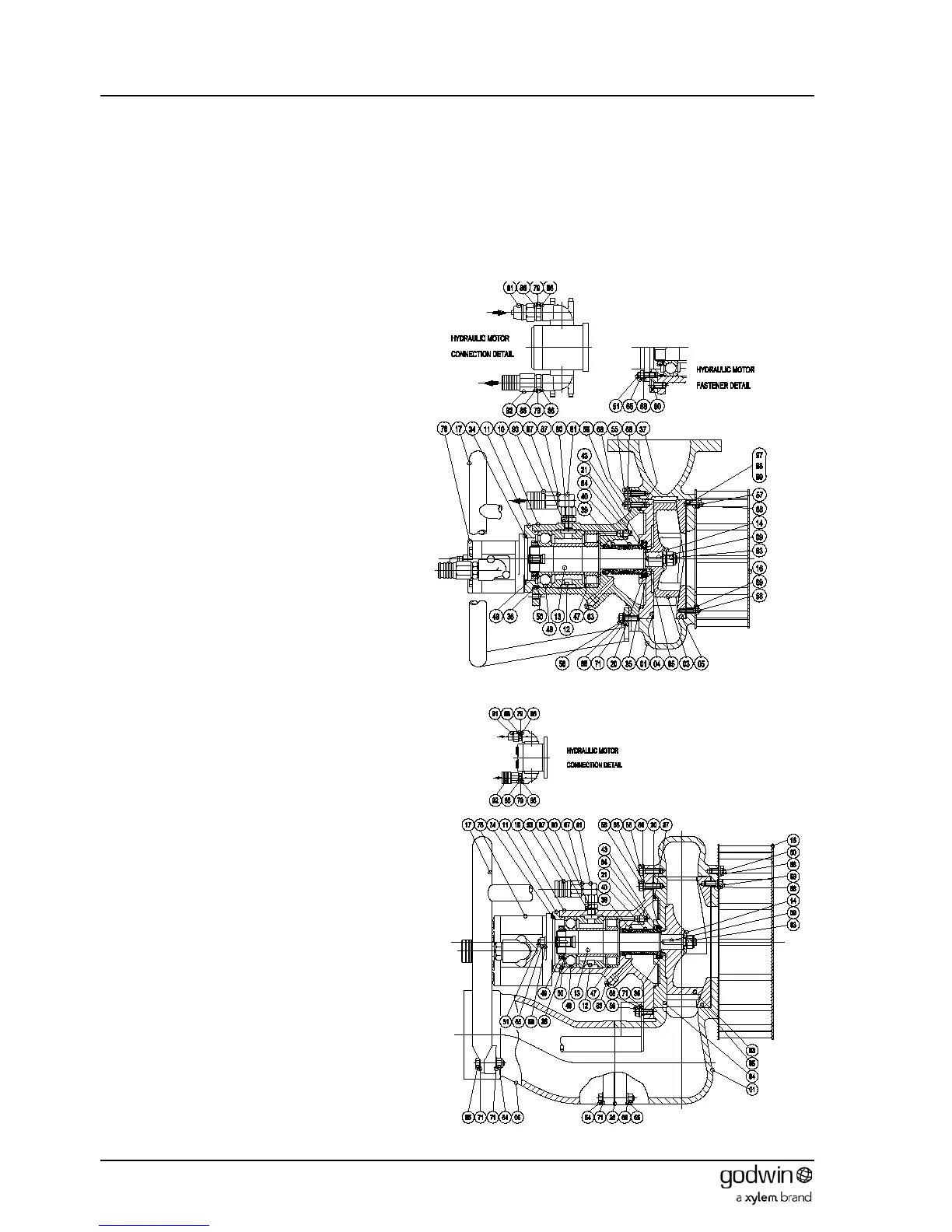

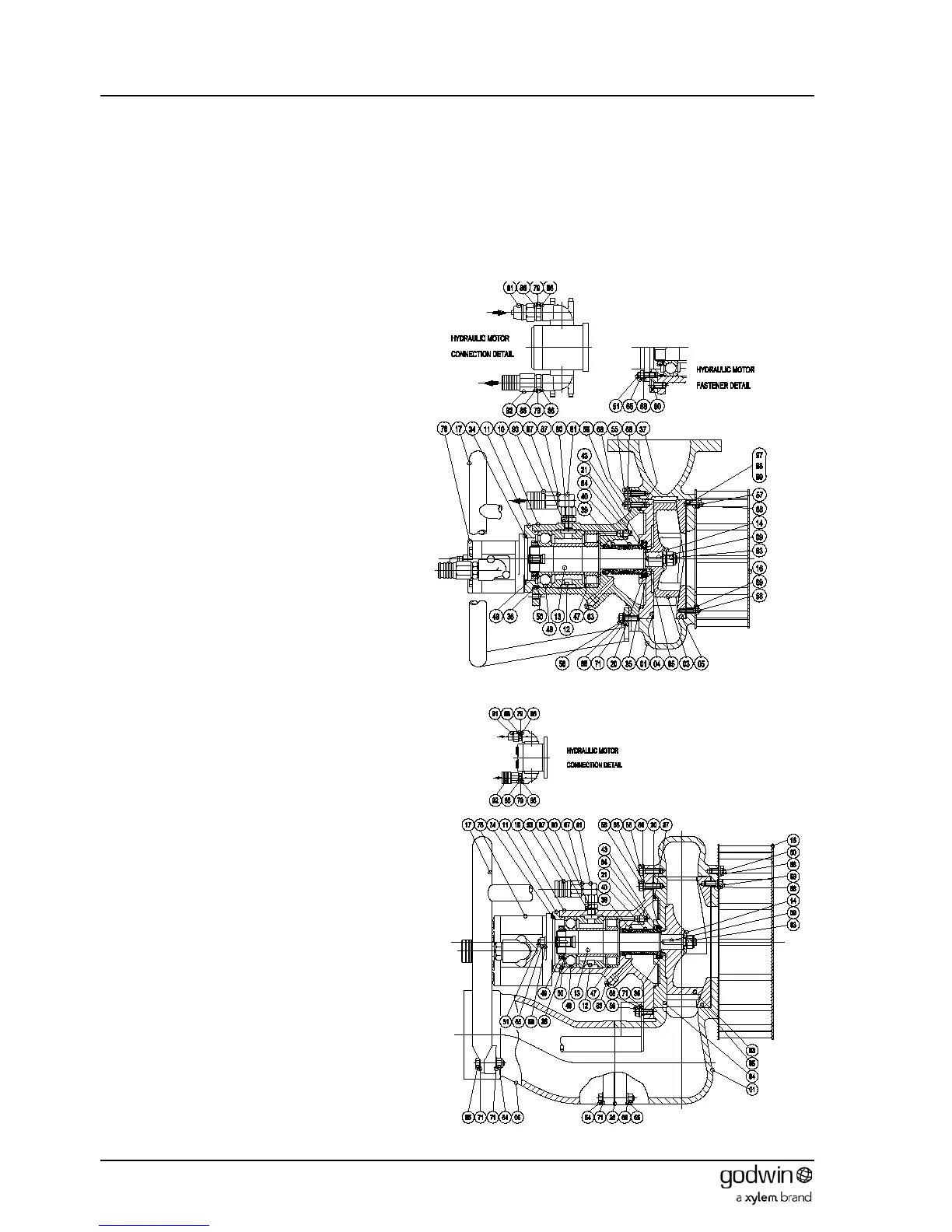

7.2 HS100, HS100-SG, HS103, HS150, HS150-SG, HS150V & HS150V-

SG pumps

NOTE! The HS100NC & HS150NC pumps differ only in volute, impeller and associated parts. Therefore these

dismantling and reassembly instructions can be followed in principle, but refer to section 7.5 for detail differences.

Note that dismantling and reassembly procedures refer to the item numbers in the illustrations and are correct for a

directly corresponding build. However because of the number of possible build configurations some interpretation of the

diagrams will be necessary for other pump variants. Some additional illustrations have been included to aid in this

purpose.

7.2.1 Dismantling

Horizontal and vertical discharges pumps are

available. Only one representative type of each

pump has been illustrated for clarity.

1. If not previously done remove the stud

adaptor (87) and associated fittings and

drain the bearing bracket of hydraulic oil.

2. Remove plug (83) and drain the seal housing

of oil.

3. HS100 pumps: -Undo set screws (56)

holding lifting bracket (17) to the pump body

(1).

HS150 pumps: - Undo nuts (64) from bolts

(55) holding lifting bracket (17) to the

extension pipe (6) and screws (59) holding

lifting bracket to the pump body (1).

Remove lifting bracket.

4. Undo set screws (HS100 – 57; HS150 – 60)

holding the strainer (16) to the pump body

(1). Remove strainer.

5. Release the screws (HS100 – 55; HS150 -

58) holding the bearing bracket, wear plate

and impeller assembly to the pump body

(1). (NOTE. These are the screws on the

larger PCD. The screws on the smaller

PCD retain the wear plate to the bearing

bracket).

6. Extract the bearing bracket assembly from the

pump body (1). The front wear plate (5) can be

removed from the pump body if required by

removing the screws (HS100 – 58; HS150 - 59).

7. Place a bar through the vanes of the impeller

(3) to lock it in position and prevent rotation.

Unscrew (RH thread) and remove the impeller

retaining nut (63) and washer (14). Note that

the nut has a nylon insert that provides a self-

locking function. The nut will therefore remain

stiff to turn until this nylon insert is clear of the

shaft.

8. Pull the impeller (3) off the shaft (13) and

remove the key (9). Two off M10 tapped jacking

screw holes are provided in the boss of the

impeller if required to aid in its removal.

9. Release the screws (HS100 – 55; HS150 - 58)

holding the rear wear plate (4) to the bearing

bracket assembly. Remove the wear plate to

expose the mechanical seals (40 & 39). The

wear plate contains a seal seat (20) that is

removed by releasing the circlip (43).

10. Slide the mechanical seals (40 & 39) off the

shaft (13) and extract the seal seat from the

bearing bracket (10).

Figure 7 Typical HS100 pump

Figure 6 Typical 15022 pump

Loading...

Loading...