Book No.: 95-0014-0000/A OPERATOR

Issue: 06 HANDBOOK

Page 29 of 30

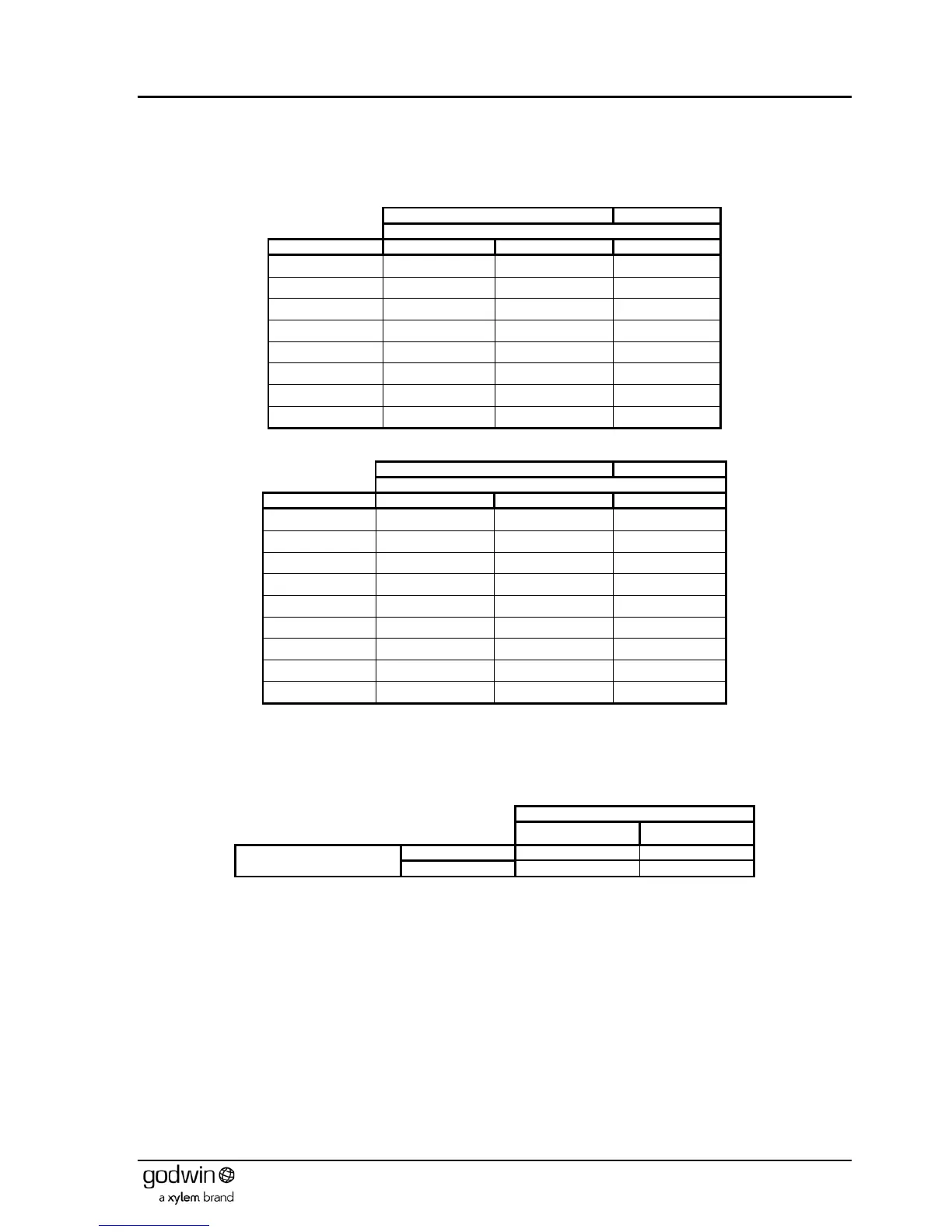

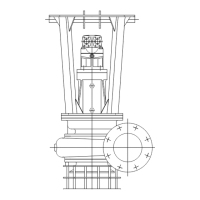

10.4 Fastener Torques

The following tables give the recommended tightening torques for general purpose metric and UNC fasteners. They are to be

used only when the joint is metal to metal (i.e. no joints or gaskets) and no special figures (e.g. for impeller retaining bolts) have

been quoted.

¼” - 20 13.5 5.4 10.5

5/16” – 18 27.1 10.5 21.0

3/8” – 16 48.8 20 37.8

7/16” – 14 74.6 30 57.8

½” – 13 122 48 94.6

5/8” – 11 237.3 95 183.9

¾” – 10 420.4 167 325.8

7/8” – 9 664.4 266 514.9

1” - 8 1003 401 777.3

Table 1 figures are for Metric fasteners to BS3692. Steel fasteners: - Grade 8.8 for bolts, Grade 4.6 for studs, Grade 10 for nuts;

Stainless Steel fasteners: - Grade A2 or A4, Class 70 or 80.

Table 2 figures are for UNC fasteners to BS1768 Steel fasteners: -Grade S and Grade 3 for nuts; Stainless Steel fasteners: -

Grade A2.

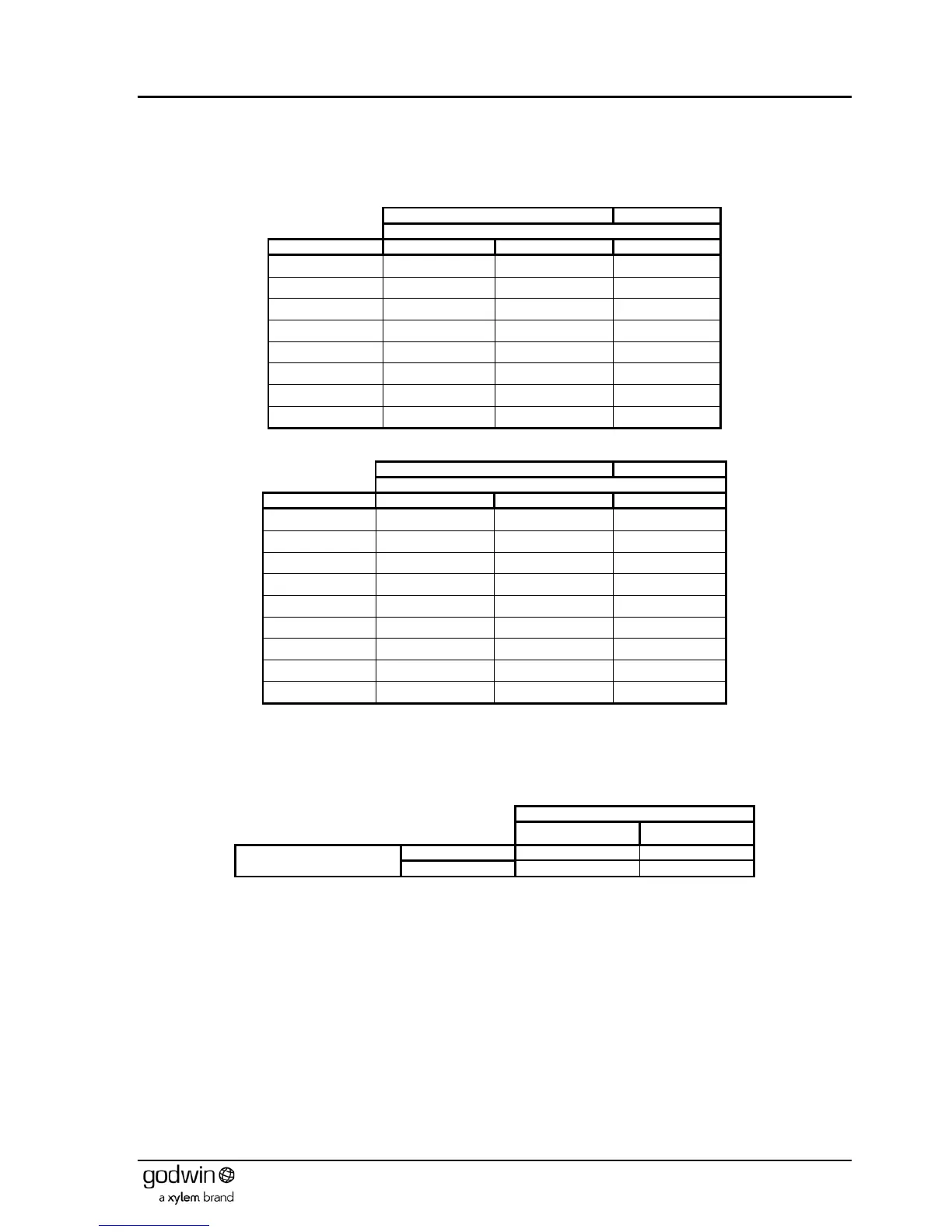

If steel fasteners are of dissimilar condition then the figures Table 1 or Table 2 must be multiplied by those in Table 3.

Loading...

Loading...