GMC-I Messtechnik GmbH 31

13 Recalibration

The measuring tasks performed with your instrument, and the

stressing it’s subjected to, influence aging of its components any

may result in deviation from the specified levels of accuracy.

In the case of strict measuring accuracy requirements, as well as

in the event of use at construction sites with frequent stress due

to transport and considerable temperature fluctuation, we recom-

mend a relatively short calibration interval of once per year. If your

instrument is used primarily in the laboratory and indoors without

considerable climatic or mechanical stressing, a calibration inter-

val of once every 2 to 3 years is sufficient as a rule.

During recalibration* at an accredited calibration laboratory (DIN

EN ISO/IEC 17025), deviations from traceable standards demon-

strated by your measuring instrument are documented. Ascer-

tained deviations are used to correct displayed values during later

use of the instrument.

We would be happy to perform DKD or factory calibration for you

at our calibration laboratory. Further information is available at our

website:

www.gossenmetrawatt.com ( Services DKD Calibration

Center or FAQs Question and Answers Regarding Calibra-

tion).

Recalibration of your instrument at regular intervals is essential for

the fulfillment of requirements according to quality management

systems per DIN EN ISO 9001.

* Examination of the specification, as well as adjustment, are not included in calibra-

tion. However, in the case of our own products, any required adjustment is per-

formed and adherence to the specification is confirmed.

14 Appendix

14.1 Sample Connection Layouts for Insulation Resistance

Measurement

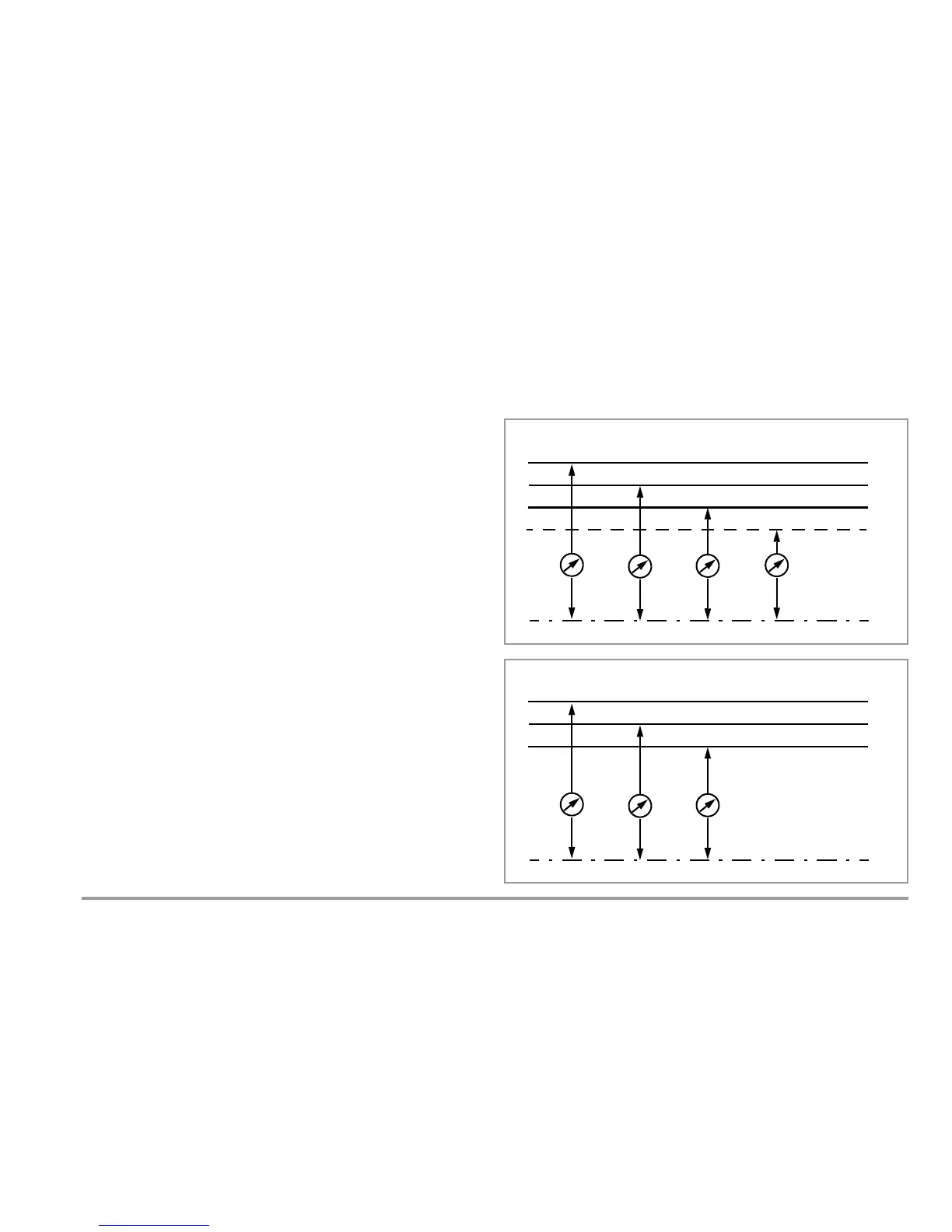

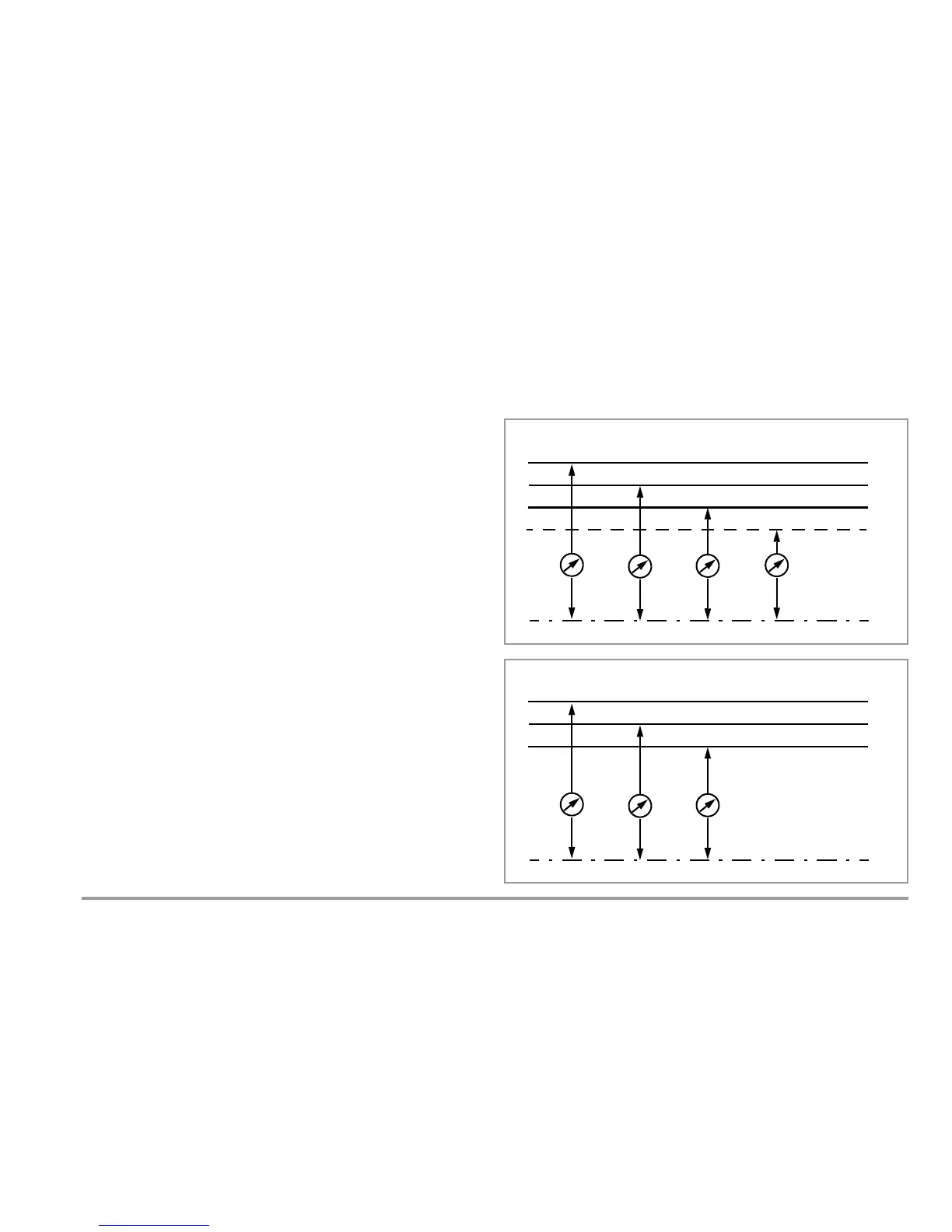

Insulation Resistance Measurement per DIN VDE 0100, Part 600

Loading...

Loading...