8 310543

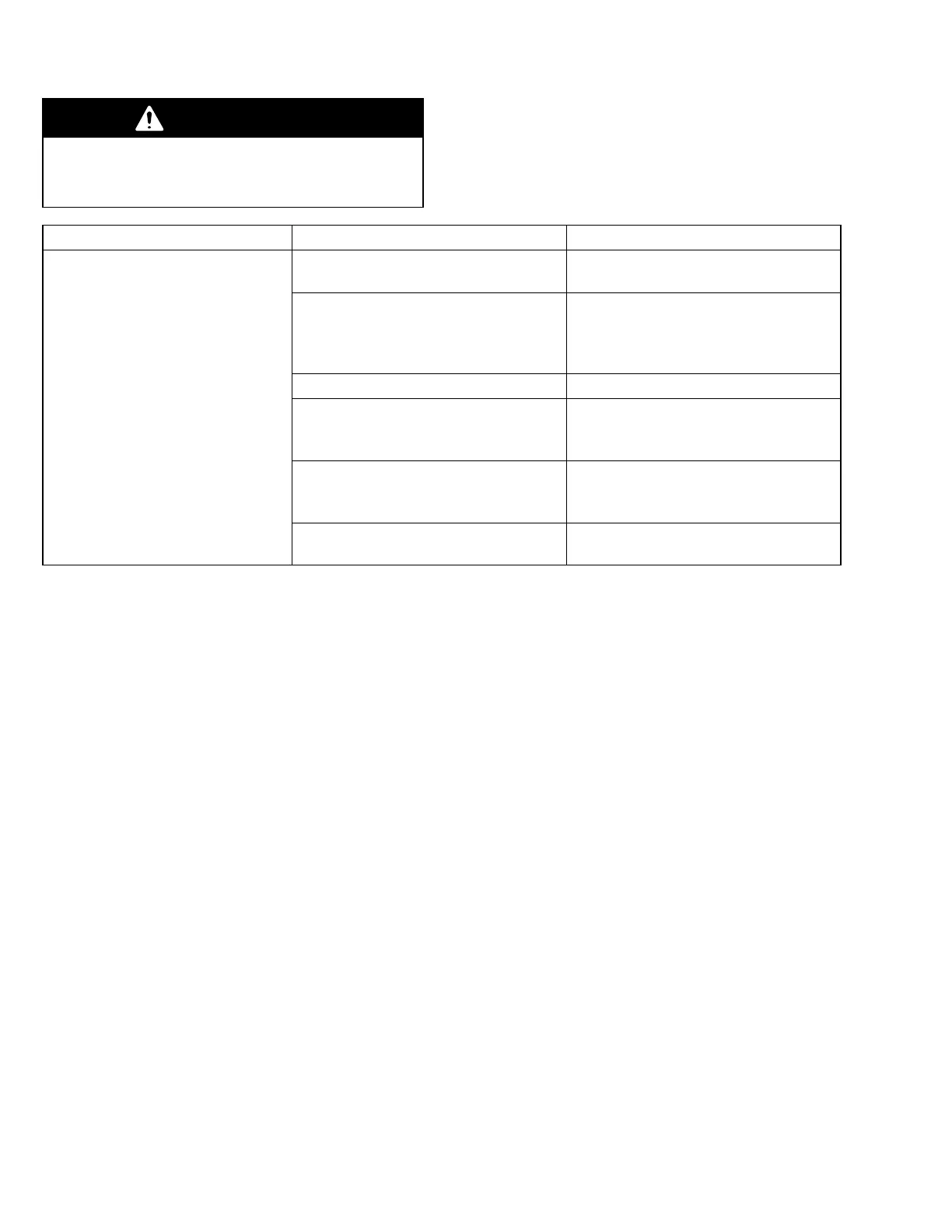

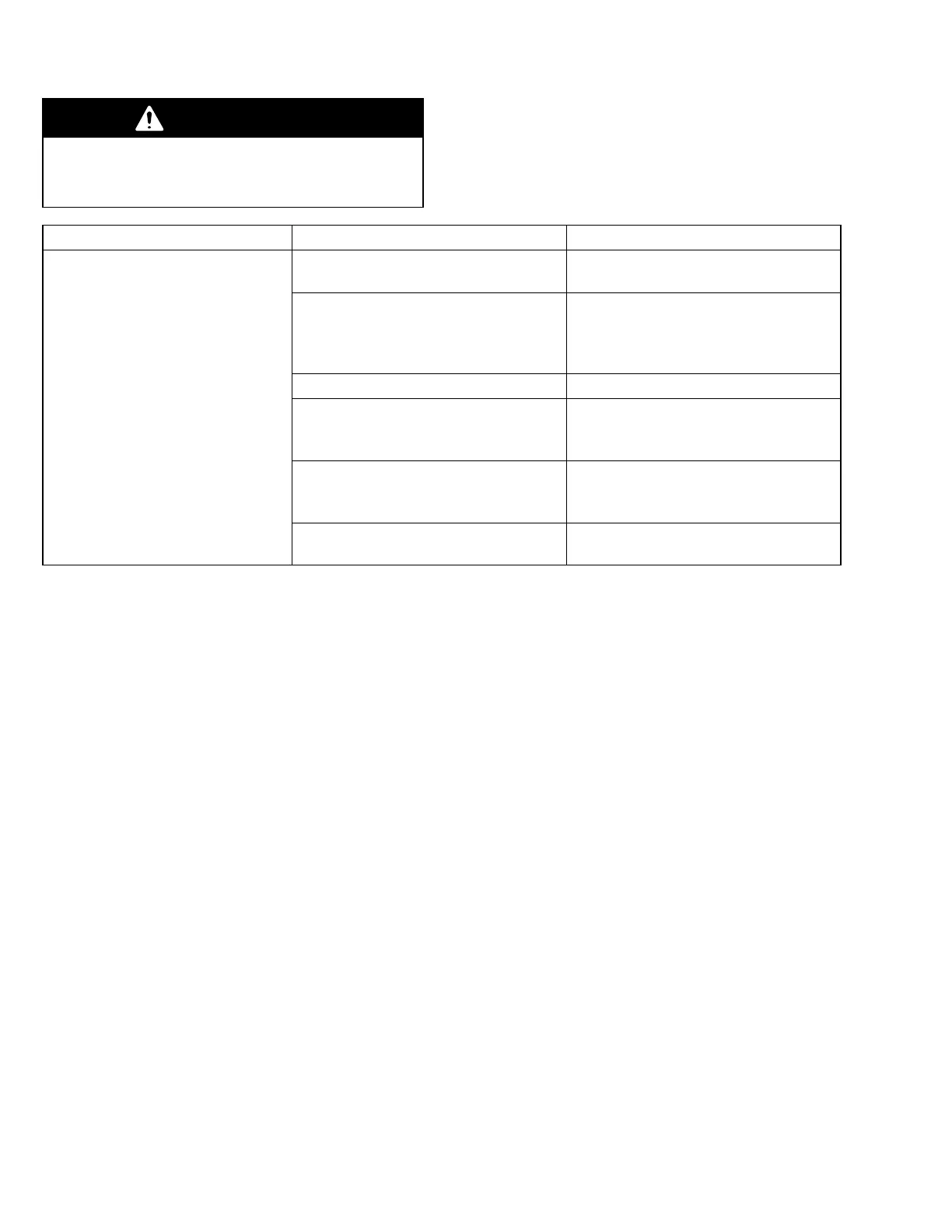

Troubleshooting

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 7.

1. Relieve the pressure.

2. Check all possible problems and solutions before

disassembling pump.

Problem

Cause Solution

Metering valve fails to dispense

when actuator is tripped.

Check nozzle for cured or foreign

fluid.

Clean or clear nozzle.

Observe the action of the needle

valve (7) and the spring (6) through

the vent hole in the valve body (18),

while cycling the valve.

Adjust the piston stroke. Disassemble

and clean the valve, if necessary.

Fluid or air hose is kinked or blocked. Clear or straighten hose.

Interrupted fluid supply. Clear supply line.

Check supply and refill if necessary.

Turn on supply pump.

Insufficient operating air pressure. Increase air pressure to 80 psi

(0.55 MPa, 5.5 bar).

Clear air line if blocked.

Worn or damaged parts. Disassemble and rebuild the valve.

Lubricate o-rings on installation.

Loading...

Loading...