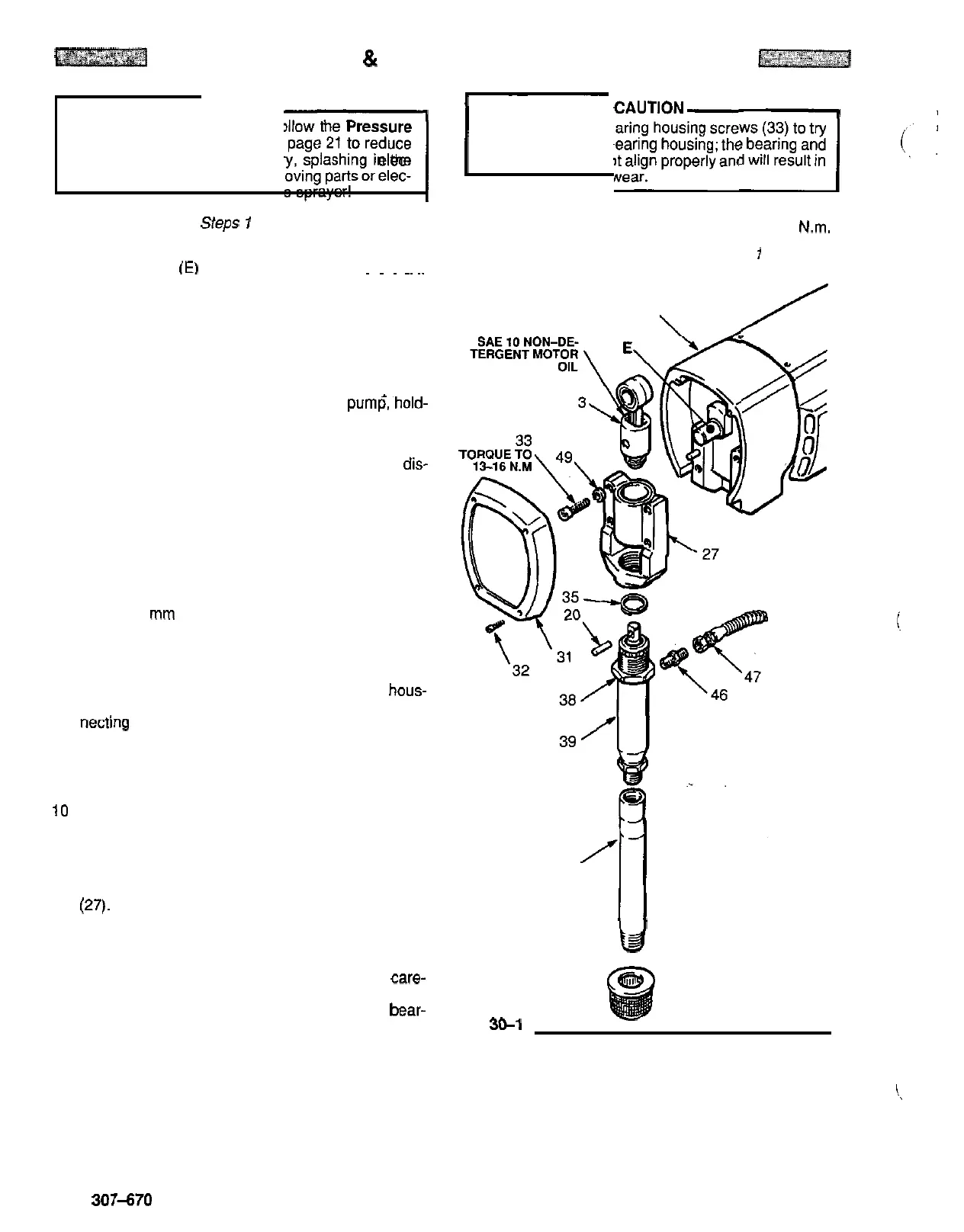

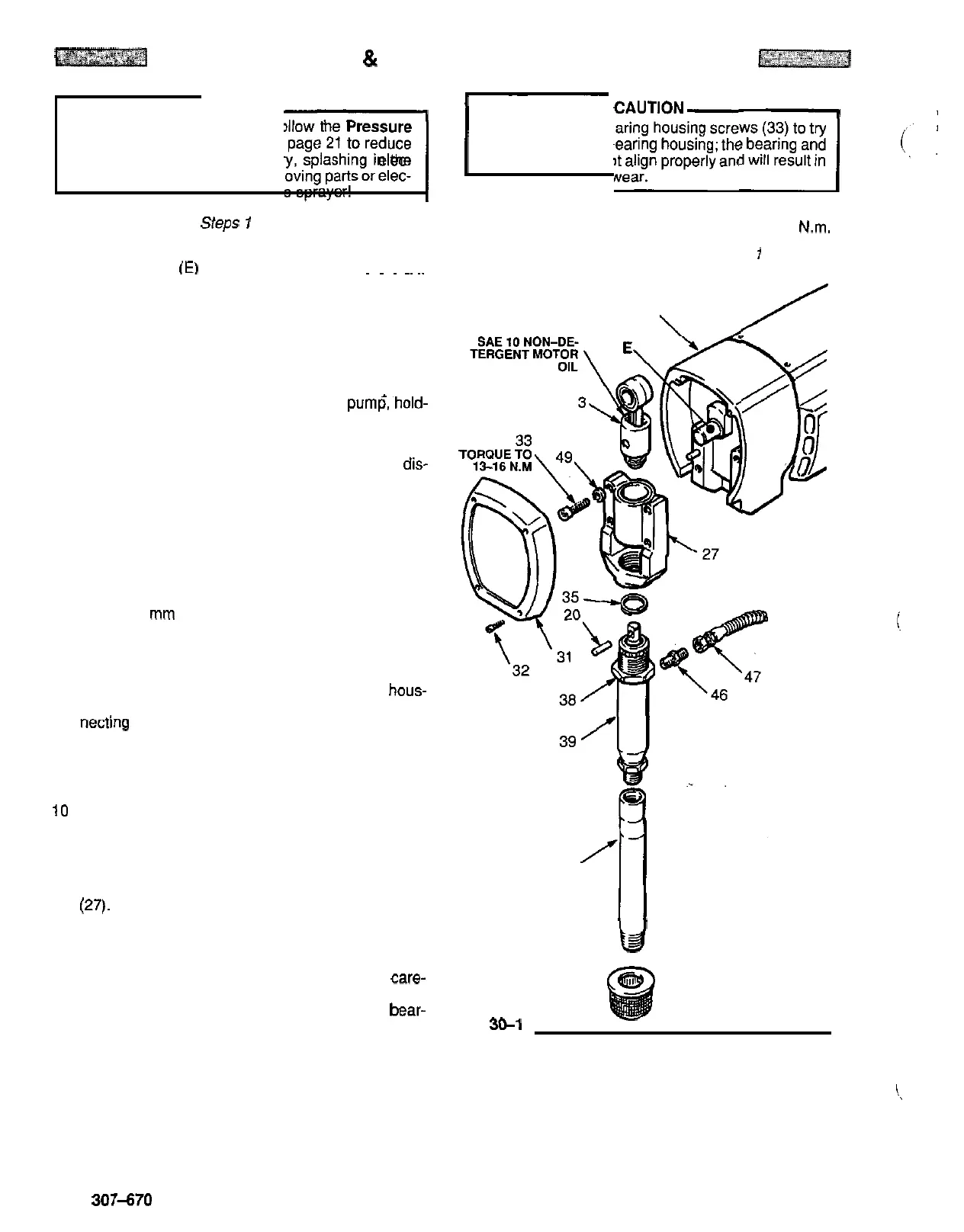

BEARING HOUSING

&

CONNECTING

ROD

REPLACEMENT

Before doing this procedure, WARNING follow

-1

the

Pressure

DO

NOT

use

the bearing cAuTIoN-1 housing screws (33) to

try

the risk of a fluid injection injury, splashing in the

Relief

Procedure

Warning

on

page 21 to reduce

to

align or seat the bearing housing; the bearing and

drive housing will not align properly and will result in

eyes or in the skin, injury from moving parts or

elec- premature bearing wear.

tric shock. Be sure to unplug the sprayer!

Refer

to

Fig

30

-

1

for Steps

7

to

74.

NOTE: Stop the sprayer at the bottom of its stroke

to

get

the crank

(E)

in its lowest Dosition. If the crank

1.

2.

3.

4.

5.

6.

7.

8.

9.

10

must be lowered manually, carefully rotate the

blades of the fan with a screwdriver.

Remove the front cover and screws (31, 32).

If

the crank

(E)

must be lowered manually, carefully

rotate the blades of the fan with a screwdriver.

ing a wrench

on

the pump intake valve

to

keep the

Unscrew the suction tube (42) from the

pum6,'hold-

pump from loosening.

placement pump outlet nipple (46).

Disconnect the pump outlet hose (47) from the

dis-

~ ~ ~ ~~ ~~

Use a screwdriver to push aside the retaining spring

(35) at the top of the pump. Push the pin (20) out the

rear.

Loosen the jam nut (38) with an adjustable wrench.

Unscrew and remove the displacement pump.

Use a

5

mm hex key wrench to remove the four

screws (33) and lockwashers (49) from the bearing

housing (27).

Lightly tap the lower rear of the bearing housing (27)

with a plastic mallet to loosen it from the drive

hous-

necting rod assembly (3) straight

off

the drive hous

-

ing (2). Then pull the bearing housing and the con

-

ing.

Inspect the crank

(E)

for excessive wear and replace

parts as needed.

Evenly lubricate the inside of the bronze bearing in

the bearing housing with high quality motor oil. Liber

-

ally pack the roller bearing in the connecting rod as

-

sembly (3) with bearing grease.

14. Install the screws (33) and lockwashers

(49)

on the

procedure continued

on

page

3

7

bearing housing and tighten evenly

to

13

-

16 N.m.

FILL

CAVITY

WITH

42

11. Assemble the connecting rod and bearing housing

(27).

12. Clean the mating surfaces of

the

bearing and drive

housings.

W

13. Align the connecting rod with the crank (E) and care-

the holes in the bearing housing (27). Push the bear-

fully align the locating pins in the drive housing with

with

a

plastic mallet.

ing housing

onto

the drive housing or tap

it

into place

Fig

3CL1

30

307470

Loading...

Loading...