STALL

PRESSURE

CALIBRATION

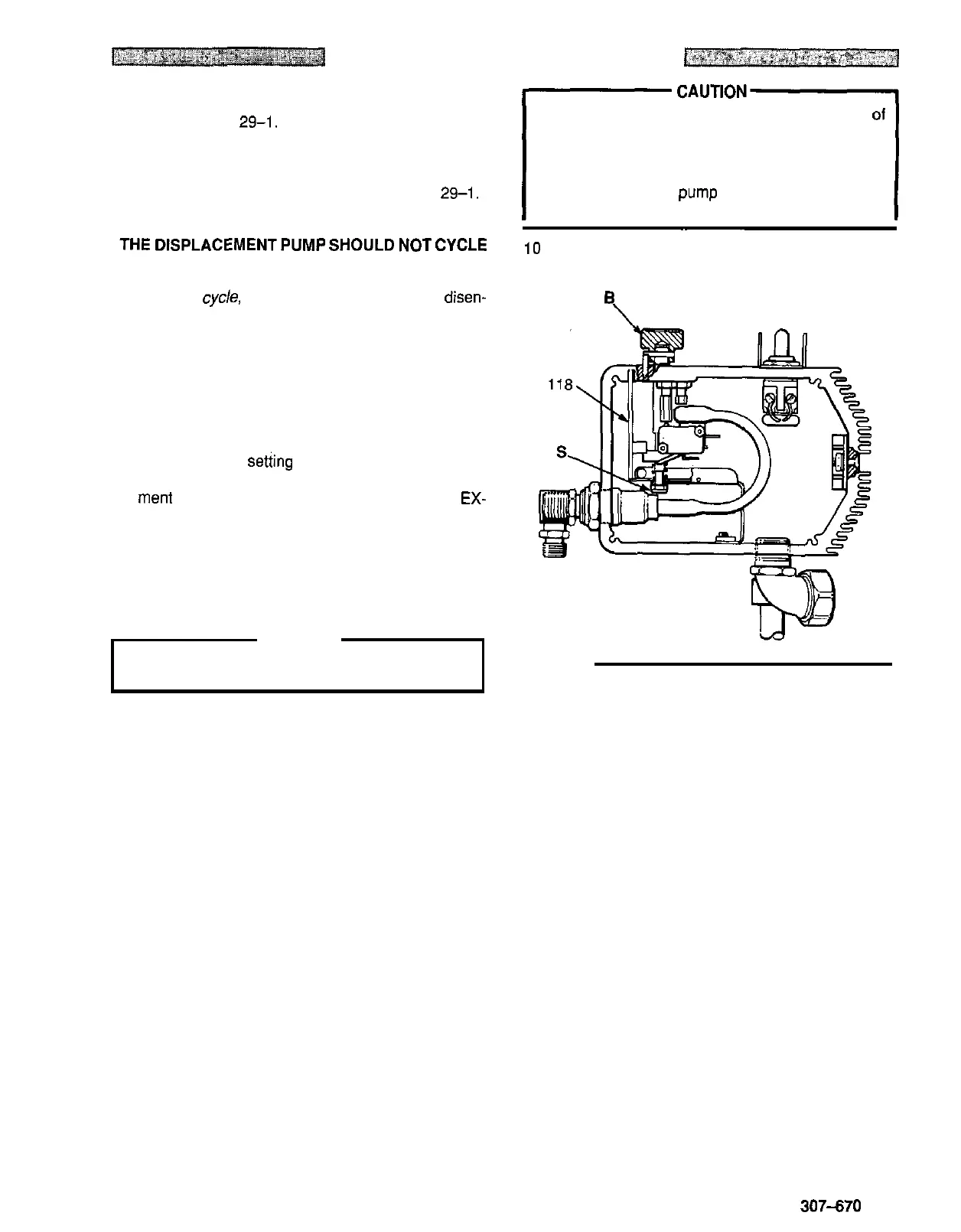

6.

Use a 9 rnm ignition wrench

to

turn the pressure ad

-

justment nut

(S)

counterclockwise about

two

full

turns. See Fig 29-1.

To

prevent

pump

corrosion, flush the water out

of

the pump, hose and gun with mineral spirits.

Be

sure

to close the drain valve, first. ,Use the lowest

7.

With the pressure control knob

(B)

at the minimum

pressure necessary to flush. Follow the

Pressure

setting, turn the sprayer switch

ON.

See Fig 29-1. mineral spirits in the pump

to

protect it until you are

Relief Procedure Warning

on page

21.

Leave the

ready to spray again.

THE DISPLACEMENT PUMP SHOULD

NOT

CYCLE

10

Remove the test gauge assembly and reinstall the

~~

-

plug. Flush out water with mineral spirits.

If

it does cyde, shut the sprayer switch OFF, disen-

gage the gun satety latch, trigger the gun into a

grounded waste container until pressure is relieved,

and engage the latch again. Turn the nut

(S)

a little

further clockwise. Turn the sprayer on again to be

sure

THE

PUMP

DOES

NOT

CYCLE.

8.

Slowly

turn the pressure control knob

(B)

clockwise

to the maximum

setting and hold it there. Use a9 rnm

ment nut

(S)

clockwise until the test gauge reads

EX-

ignition wrench to slowly turn the pressure adjust

-

ACTLY

207 bar.

9. The calibration procedure is now completed.

WARNING

Follow the

Pressure Relief Procedure Warning

on

page

21.

Fig

29

-

1

307470

29

Loading...

Loading...