TABLE

OF

CONTENTS

...............................

Warnings 4

Introduction 2

Setup

....................................

6

Operation

.................................

8

Shutdown

&

Care

.........................

10

Troubleshooting Guide

.................................

Flushing Guidelines

.......................

11

Motor Won't Operate

....................

13

Low Output

............................

16

No

Output

.............................

17

Excessive Pressure Fluctuations

...........

17

Motor

Is

Hot and Runs Intermittently

........

18

Electrical Short

.........................

18

SpinTest

.............................

19

BridgeTest

............................

20

List of Tools

...........................

21

General Repair Notes

...................

21

Filter Replacement

......................

22

ON/OFF Switch Replacement

.............

23

Microswitch Replacement

................

23

Repair

Power Supply Cord Replacement

........

-

.

22

Bridge.Rectifier Replacement

..............

24

Choke Replacement

.....................

25

Varistor Replacement

....................

25

Circuit Board Replacement

................

26

Pressure Control Replacement

.............

27

Pressure Control Calibration

...............

28

Bearing Housing

&

Drive Housing

Replacement 32

Conn. Rod

Replacement, 30

Motor Brush Replacement

.................

33

Capacitor Replacement

...................

34

Motor Replacement

...................... 35

..............

...............

Parts Lists and Drawings

Complete Sprayer

.......................

38

Pressure Control Assembly

................

40

NOTE:

See manual 307

-

793, supplied, for the displace

-

ment pump repair instructions and parts list.

Technical Data 43

Accessories 42

.............................

Warranty Back Cover

Dimen.sions.. 43

..............................

.............................

.........................

INTRODUCTION

ULTRA@

433

BASIC COMPONENTS

Your new Ultra@ 433 Sprayer functions and operates dif

-

ferently than other airless paint sprayers. This section will

help you become familiar with the sprayer before operat

-

ing it.

Pressure Control

The pressure control includes an

ONlOFF switch for the

sprayer, the pressure adjusting control knob and a pres

-

sure sensing device. Its function is to control the motor

speed

so

that the sprayer maintains constant fluid pres

-

sure at the pump outlet.

Motor

tor brushes. Its function is to drive the displacement

The DC motor has sealed bearings and replaceable

mo-

pump at the rate needed to supply sufficient paint volume

at the selected pressure. Working together, the pressure

control and motor cause the pump to cycle whenever

there is fluid or pressure demand. When the pump is cy

-

cling, the motor sounds like an automobile starter crank

-

ing. When the pump

is

not cycling, the motor may hum

intermittently until the fluid pressure stabilizes, then the

to the sprayer and it will stay pressurized and ready to

motor will shut itself

off.

However, there will stili be power

use

unless you manually shut it off and relieve pressure.

Because the motor is DC, it

is

less sensitive to low volt

-

age or voltage fluctuations than an AC motor, and an ex

-

tension cord of up to 45 m can be used.

Drive Assembly

The sealed drive assembly transfers power from the DC

motor to the displacement pump.

Displacement Pump

The positive displacement, volume

-

balanced pump pro-

vides equal fluid delivery on both the up and down pump

strokes. The pump has a wet

-

cup which, when filled with

Graco Throat Seal Liquid,

helps prevent damage to the

throat packings and piston rod.

2

307-670

Fluid Filter

The fluid filter strains the paint to help avoid clogs in the

hose and spray tip. The filter includes a reusable element

and a pressure drain valve for relieving fluid pressure.

Hoses

The grounded, nylon spray hoses have spring guards on

both ends.

The152 m hose has a 1/4 in.

ID.

The

0.9

m,

3/16 in.

ID

whip hose allows flexible gun movement. The

nylon hose material acts as a pulsation dampener to ab

-

sorb pressure fluctuations.

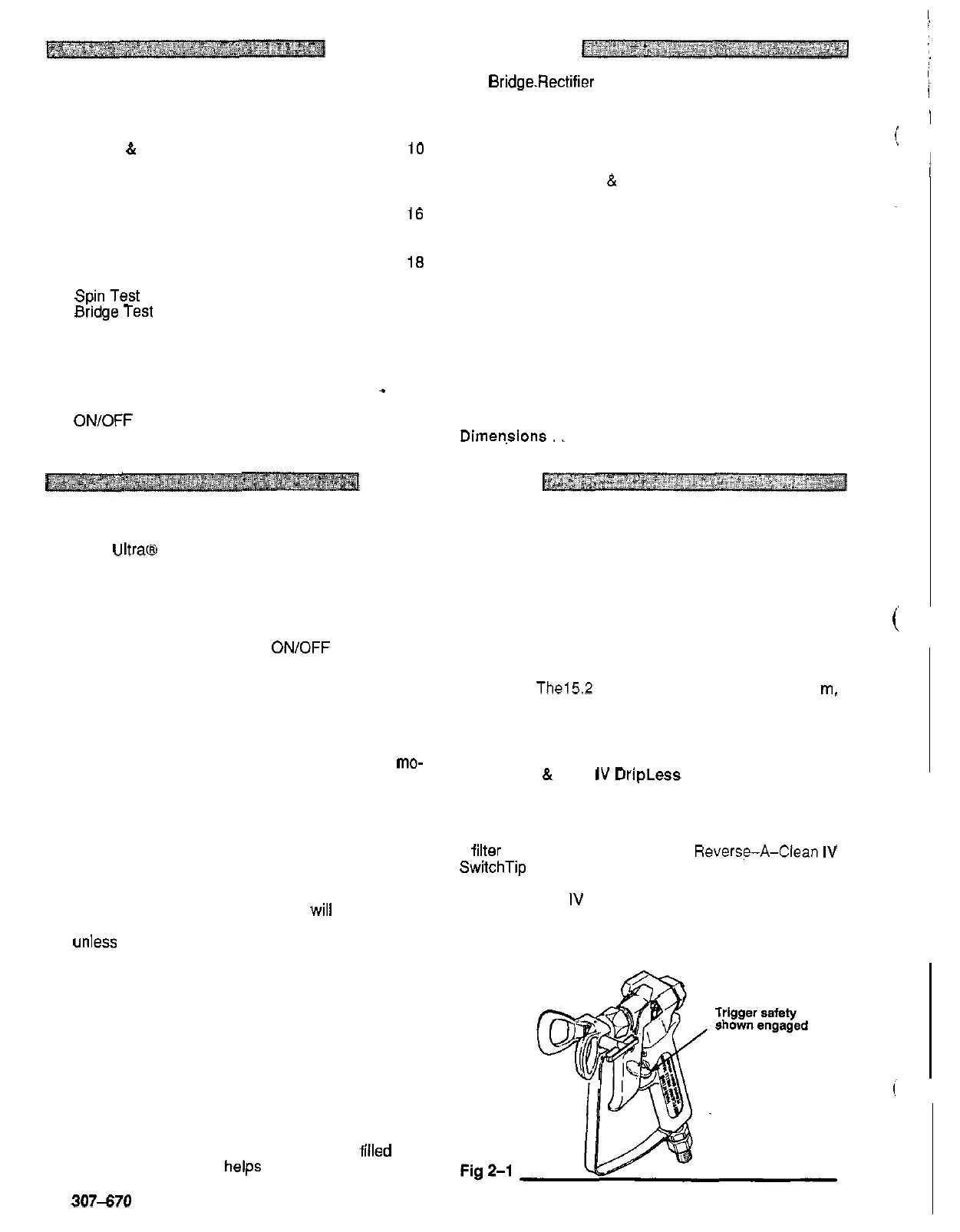

Spray Gun

&

RAC

IV

DripLess Tip Guard

which prevents accidental triggering when it

is

engaged.

Graco high pressure spray guns have a trigger safety

See

Fig Z-I.

The gun provided with the sprayer also has

a

filter for final paint straining. The ReverseA-Clean IV

the spray tip without removing

it

from the gun. The Re

-

SwitchTip uses high pressure fluid to remove clogs from

which helps reduce the risk of fluid injection injury.

verse

-

A

-

Clean IV DripLess tip guard is a safety feature

Loading...

Loading...