IO

OUTPUT

TYPE OF PROBLEM WHAT TO CHECK

If check

Is

OK,

go

to

the next check.

Motor runs and pump

strokes

1. Check paint supply.

2. Check for clogged intake strainer.

3. Check for

loose

suction tube or fittings.

4.

Check

to

see

if

intake valve ball and pis

-

ton ball are seating properly.

See

man

-

ual 307-793.

5.

Check for leaking around throat packing

aged packings. See manual

307-793.

nut which may indicate worn or dam-

Motor runs but pump does

rodpin. See page 31.

not

stroke

1. Check displacement pump connecting

I

2.

Checkconnectingrodassembiyfordam-

age.

See

page 30.

3.

Be sure crank'in drive housing rotates;

plug in sprayer and turn

on

momentarily

to

check. Turn

off

and unplug sprayer.

See

page 30.

~~...~~

~

-

"

If

check

is

not

OK,

refer to this column.

1.

Refill and reprime pump.

2. Remove and clean, ihen reinstall.

3. Tighten; use thread sealant or sealing

tape

on

threads

if

necessary.

4.

Remove intake valve and clean. Check

balls and seats for nicks; replace

if

neces

-

sary. See manual 307-793.

5.

Replace packings.

See

manual 307-793.

Also

check piston valve seat for hardened

paint or nicks and replace

if

necessary.

1. Replace pin

if

missing.

Be

sure retaining

spring is fully

in

groove all around con

-

necting rod. See page

31,

2. Replace connecting rod assembly.

See

page 30.

3. Check drive housing assembly for dam

-

age and replace

if

necessary. See page

32.

'YPE OF PROBLEM

spray pattern varlations.

WHAT TO CHECK

If

check Is

OK,

go

to the next check.

1.

Be sure both G1 and G2 leads from

bridge (308) to circuit board (118) are

firmly connected. See page 26.

2. Check stall pressure. Refer to Calibra

-

tion procedure on page 28.

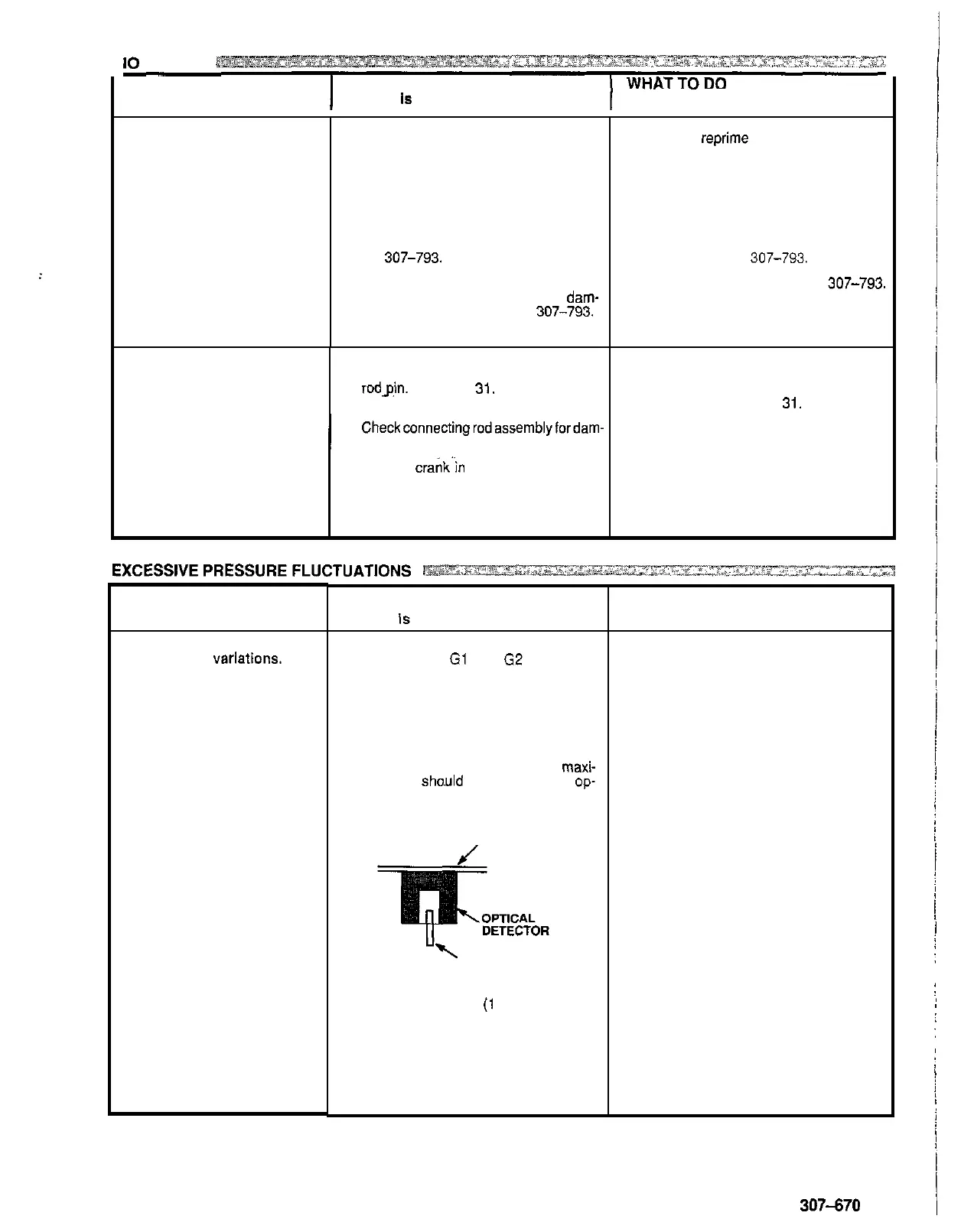

3. Check bourdon tube flag and detector

position. Turn pressure setting to

maxi-

tical detector slot of circuit board.

mum; flag

sho.uld

not

drag or bind in

op-

CIRCUIT

BOARD

''\

FLAG

4.

Check circuit board

(1

18)

by

substitut

-

ing with a good board. See page 26.

5.

Check

LOW

OUTPUT

section on page

16.

WHAT TO

DO

If check

is

not

OK.

refer

to

this column.

1.

Reconnect securely.

See

page 26.

2. Calibrate pressure control. See page

3. Carefully bend flag into alignment with

detector

slot

to see

if

that corrects prob

-

lem.

If

not,

replace bare pressure con

-

trol assembly (301). Calibrate pressure

control after reassembly.

28.

4.

Replace circuit board.

See

page 26.

307-670

17

Loading...

Loading...