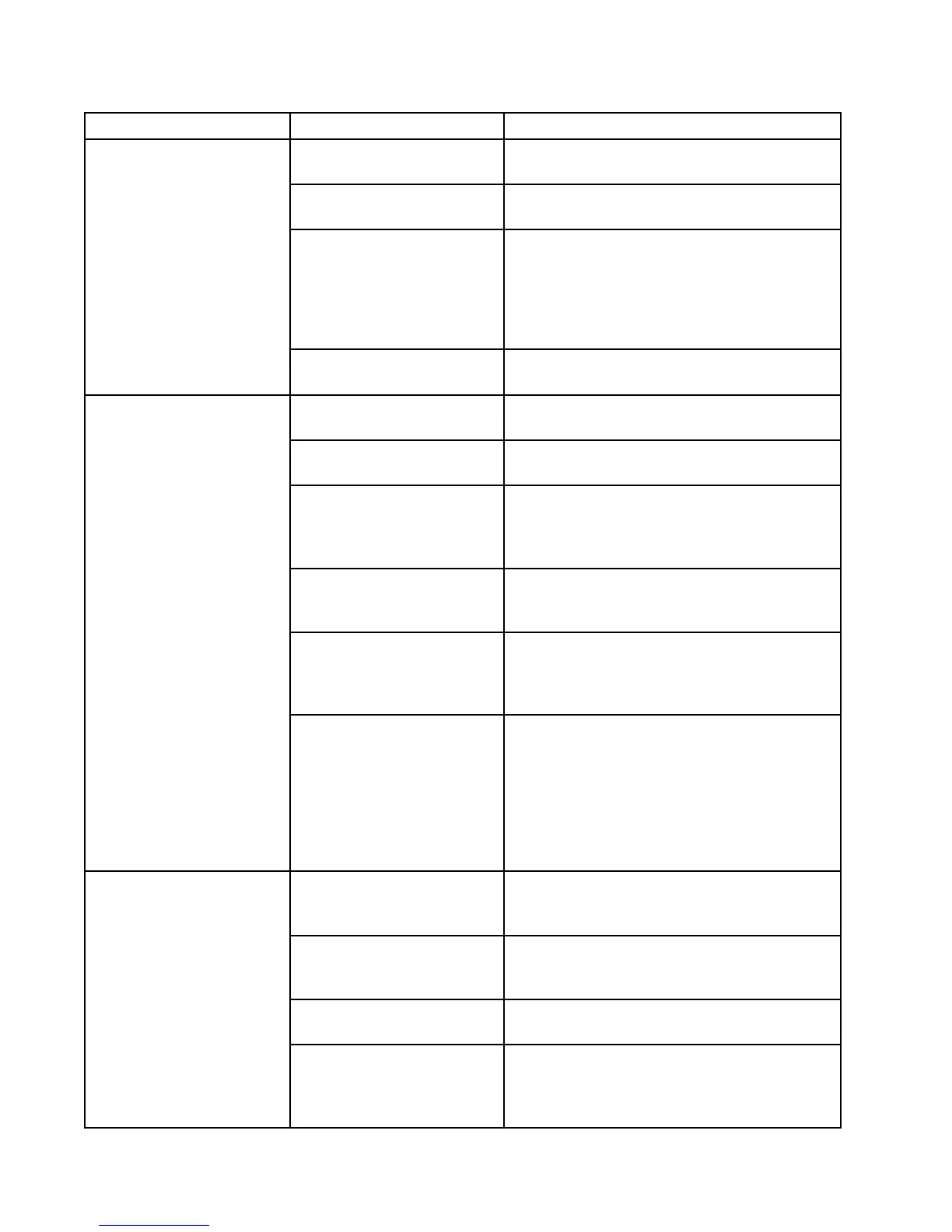

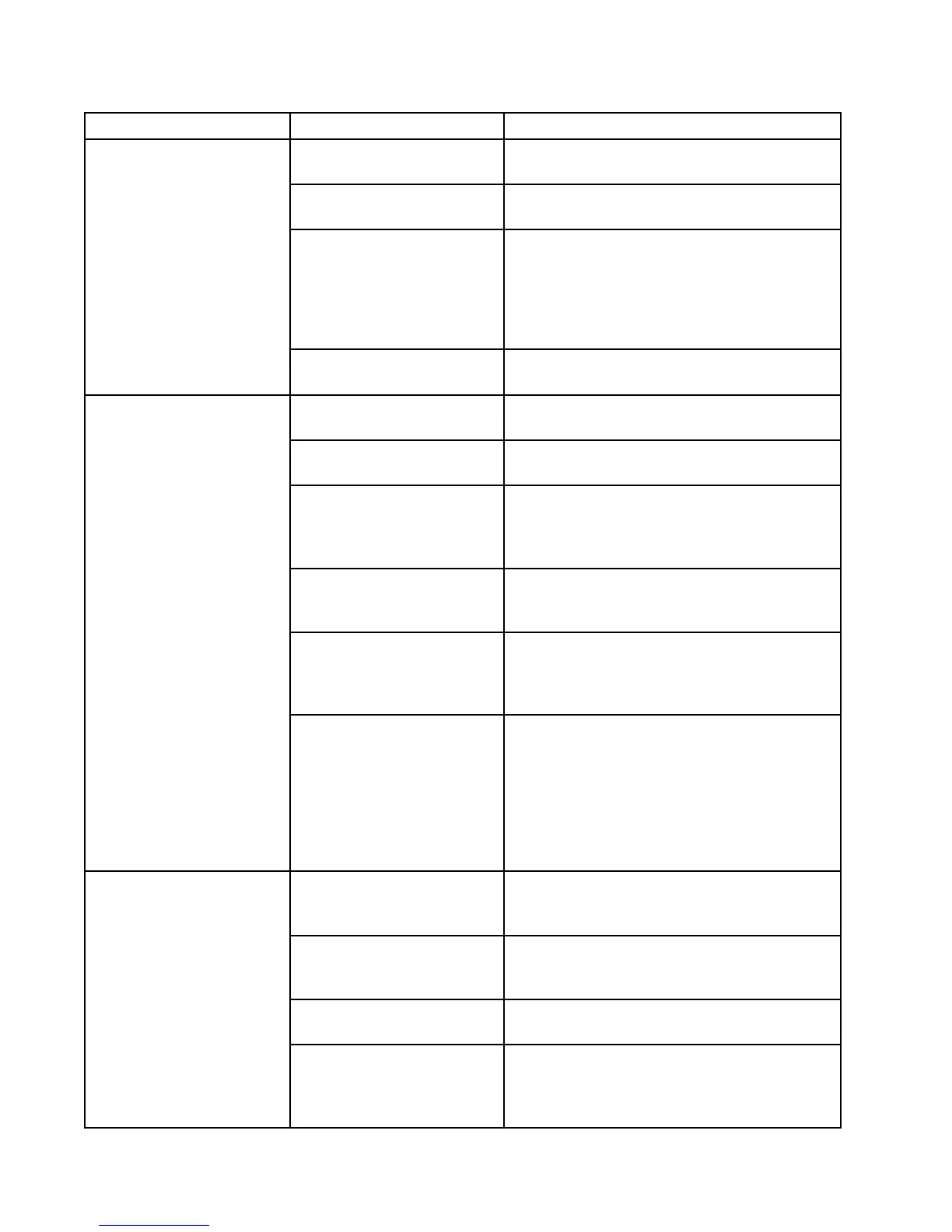

Troubleshooting

Problem Problem

Problem

Cause Cause

Cause

Solution Solution

Solution

Themainairregulatoris

stuckopen.

SeeRepairingtheMainAirRegulator,page29.

Theblastcontroltubingis

notconnectedproperly.

Ensureairtubingisroutedandconnected

properly.SeeHoseSchematic,page42.

Electricblastcontrolcircuitis

malfunctioning.

Inspecthosecablefordamagedorshorted

wiring.Checkbatteryandcontrolpanel

connections.EnsureDCpowersourceis12V.

Check3Afuseinsidecontrolpanelandreplace

itifnecessary.Checkcurrentowincircuit,if

currentexists,replacerelay.

Theblastcontrolisnot

engagedbutblastingstill

occurs.

Pneumaticblastcontrol

circuitismalfunctioning.

SeePneumaticBlastControlCircuit,page28.

Incorrectabrasiveisbeing

used.

Usethecorrectabrasive.See

AbrasiveMeteringValveSettings,page18.

Thepotdoesnothavea

sufcientamountofabrasive.

Rellthepotwithabrasive.See

RellingthePotwithAbrasive,page20.

Thepotpressuresettingis

incorrect.

Performthepressurereliefprocedure(see

PressureReliefProcedure,page10)

andresetpotpressure(see

SettingUptheEquipment,page13).

TheAuto-Ventvalvedoes

notventairwhenthepotis

lled.

MakesuretheAuto-Ventvalveisworking.

PerformtheAuto-Ventcleaningprocedure

(seeCleaningtheAuto-VentValve,page32).

Thediaphragmvalveis

malfunctioning.

Performthediaphragmushprocedure(see

FlushingtheDiaphragmValve,page30).

Ifushingdoesnotsolveproblem,see

RepairingtheDiaphragmValve,page31.

Theblastspraypatternis

irregular.

Thereisblockageinsidethe

potorinsidetheabrasive

hosebetweenthepotand

thepanel.

Makesuretheballvalveisclosed,then

disconnectthecam-lockcoupler.Openthe

abrasiveballvalveslightlyandmakesure

abrasiveisowingfromtheabrasivehose.

Ifnot,followtheshutdownprocedure(see

ShuttingDown,page21).Thoroughlyushthe

potandthemediahoseafterdrainingmedia

andwater.

Theunitisnotonalevel

surface.

Placetheunitonalevelsurface.Ifthisis

impossible,theAuto-Ventmustbeonthe

highersideoftheunit.

Theinitialpotpressureisnot

setcorrectly.

Conrmthattheauto-ventvalveisworking

andsetinitialpotpressure30psi(2.0bar,0.2

MPa)abovetheblastpressure.

TheAuto-Ventis

malfunctioning.

Performauto-ventcleaningprocedure(see

CleaningtheAuto-VentValve,page32).

Astronghoserecoiloccurs

frequentlywhentheblast

controlswitchisengaged.

Thediaphragmneedstobe

ushed.

Performthediaphragmushprocedure(see

FlushingtheDiaphragmValve,page30).

Ifushingdoesnotsolvetheproblem,see

RepairingtheDiaphragmValve,page31.

26334142F

Loading...

Loading...