Troubleshooting

Troubleshooting Troubleshooting

Troubleshooting

Examples Examples

Examples

Checking Checking

Checking

for for

for

Leaks Leaks

Leaks

1.Openthedumpvalve.Checkpotpressure

gauge,thenclosethedumpvalve.

Lookatthepressuregaugetoconrmthatall

pressurehasbeenrelievedfromthepot.

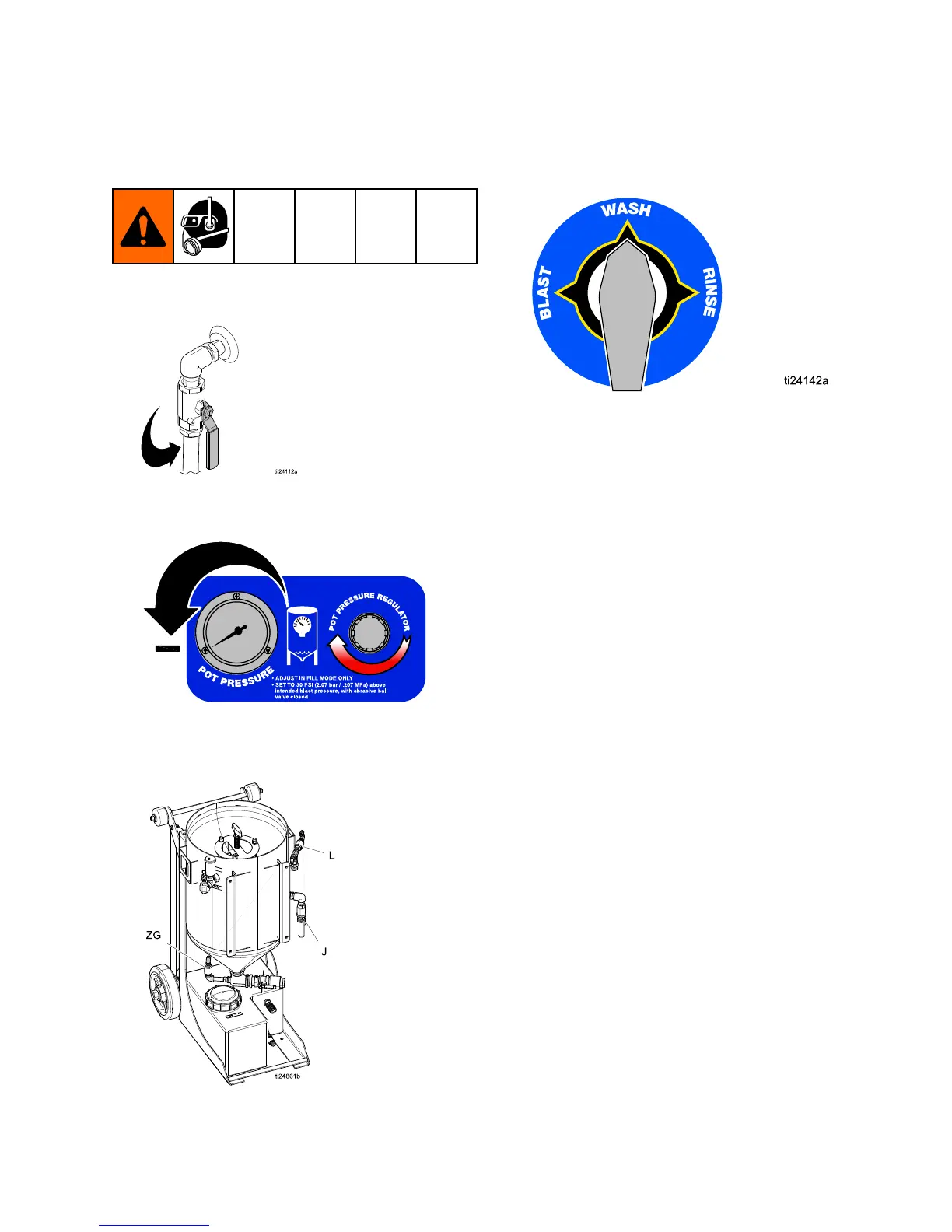

2.Disconnectthetubingattheblastcheckvalve(L)

andatthellportcheckvalve(ZG).

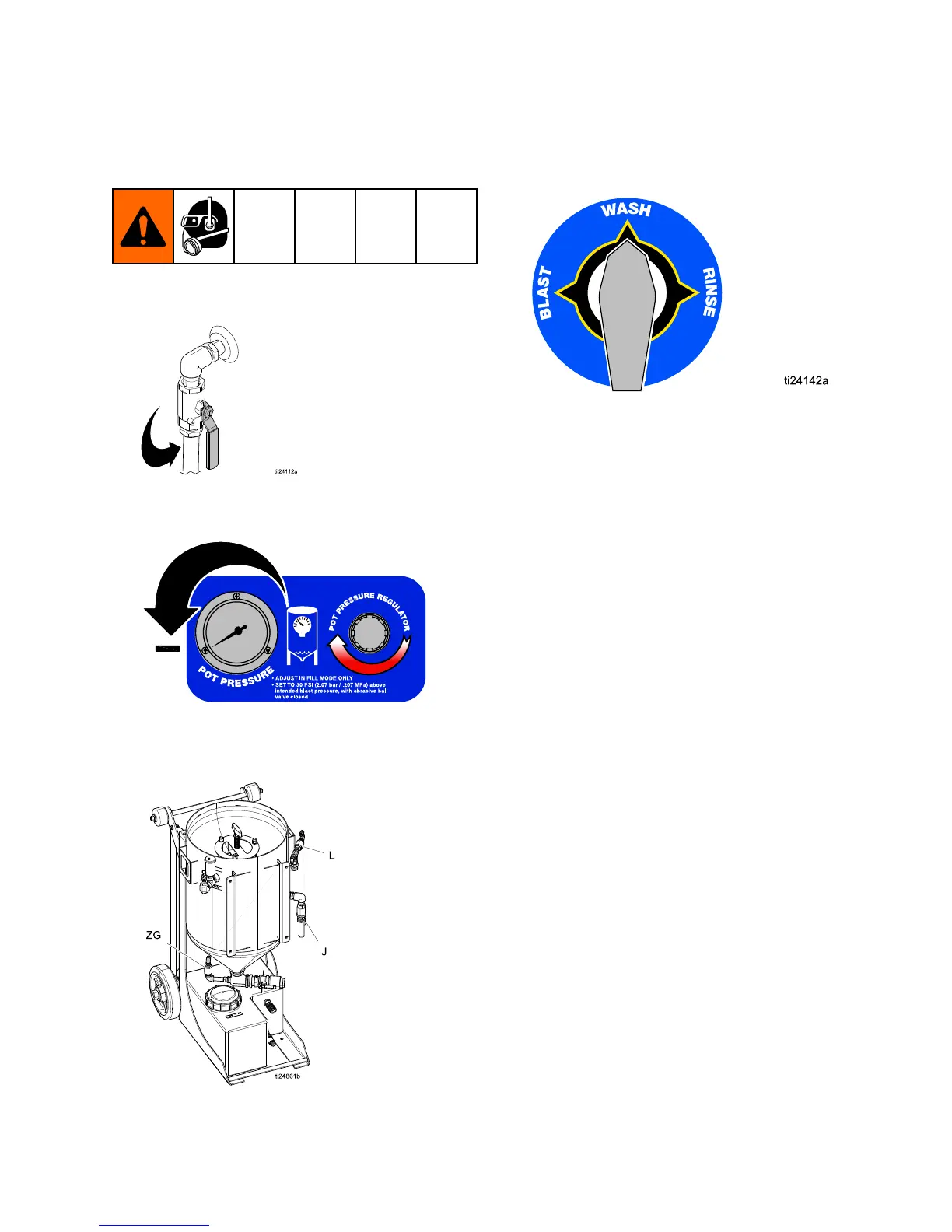

3.Makesurethepop-upisclosed.Turntheselector

valvetoWASH,thenopentheabrasiveballvalve

topressurizethepot.Setthepotpressureto145

psi(9.9Bar,0.99MPa).

4.Checkthewaterpumptoconrmthatnowater

isleakingfromtheTSLllport.

NOTE: NOTE:

NOTE:

Thepumpshouldstallafterthepot

pressurizes.Ifthepumpdoesnotstall,replace

theseals.Refertothepumpmanualforrepair

information.

5.Checkforanywaterleakingfromeithercheck

valve.Ifacheckvalveisleaking,itmustbe

repairedorreplaced.Ifthevalvesaredamaged,

thepotwillnotbeabletomaintainpressure.

Also,checkthepotpressurereliefvalve.Ifthe

valveisweepingatpotpressuresof145psior

less,itneedstobereplaced.

6.Closetheabrasiveballvalve,thenclosetheair

inletballvalve.Engagetheblastcontrolswitch

torelievepressureintheblastcircuit.Conrm

thatthesupplyairpressuregaugereads0psi.

7.Disconnectthequickcouplerandconrmthatthe

ballvalveisnotleaking.Replacetheabrasive

ballvalveifitisleaking.

334142F

27

Loading...

Loading...