TROUBLESHOOTING

Pressure

Relief Procedure

To reduce the risk of serious bodily injury , including

fluid

injection, splashing fluid or solvent in the eyes or

on the skin, or injury from moving parts or electric

shock,

follow this procedure whenever you shut of

f the

sprayer,

check or service any part of the spray system,

install,

clean or change spray tips, and whenever

you

stop

spraying.

1.

Engage the gun safety latch.

2.

Open the bypass valve.

3.

Depress the engine stop button.

4.

Close the fuel shutof

f valve.

5. Disengage

the gun safety

latch. Hold a metal part

of the gun firmly to the side of a grounded metal

pail,

and trigger the gun to relieve pressure.

6.

Engage the gun safety latch.

7. Open

the pressure drain valve, having a container

ready to catch the drainage. Leave the valve open

until

you are ready to spray again.

If

you suspect that the spray tip or hose is completely

clogged,

or that

pressure has not been fully relieved af

-

ter

following the

steps above,

VER

Y SLOWL

Y loosen

the tip retaining nut or hose coupling to relieve pres-

sure

gradually

, then loosen completely

.

Now clear the

tip

or hose.

WARNING

Check everything in the T

roubleshooting Chart before disassembling the sprayer

.

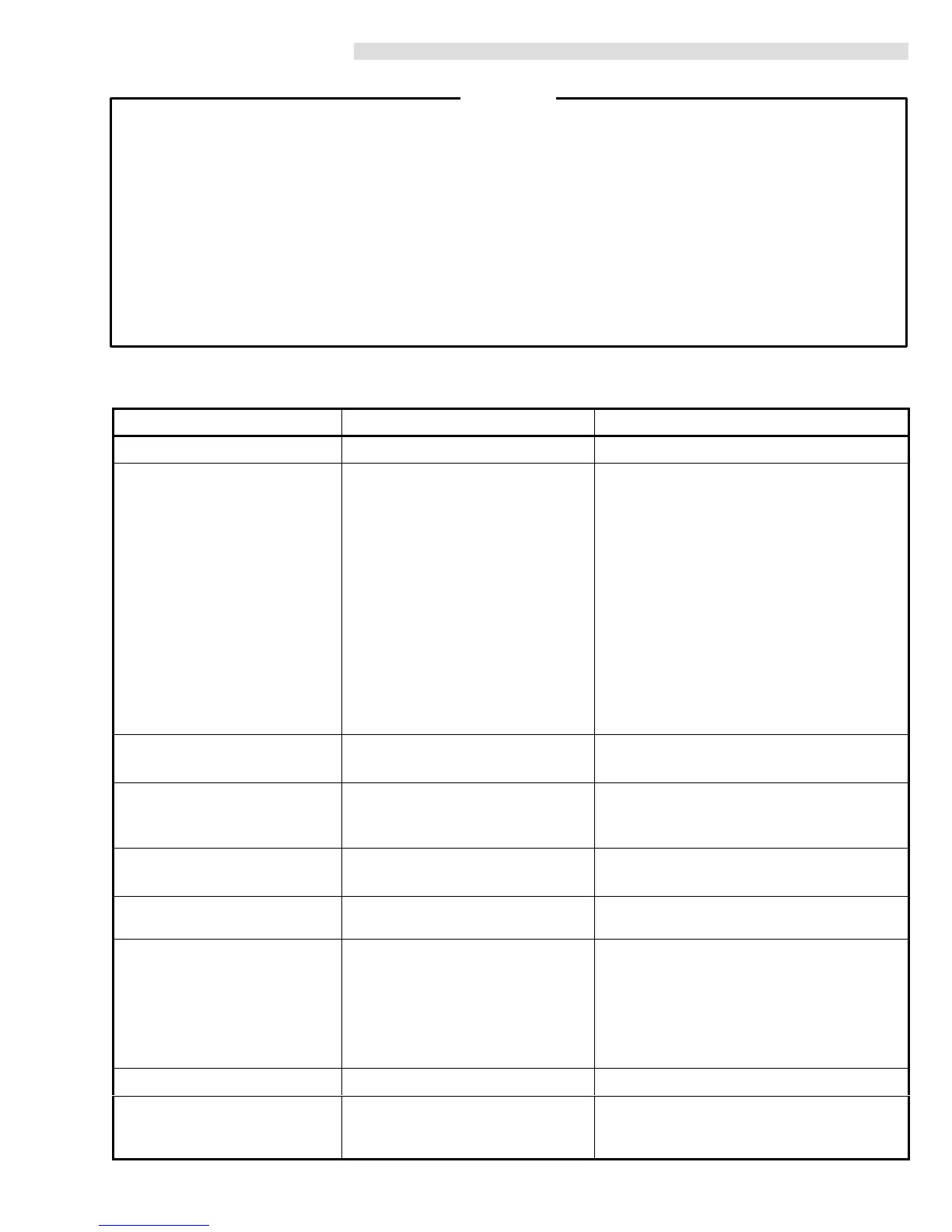

PROBLEM CAUSE SOLUTION

Gas

engine doesn’t work properly

.

Consult engine manual, supplied.

Gas engine operates, but

displacement pump doesn’t

operate.

Hydraulic motor stalled.

Pressure setting too low

.

Displacement pump outlet filter (if

used) is dirty or clogged.

T

ip or tip filter (if used) is clogged.

Hydraulic fluid too low

.

Hydraulic pump worn or damaged.

Hydraulic motor worn or damaged.

Displacement pump rod seized by

dried paint.

Depress the engine stop button. Firmly press

straight down on motor reset button. Restart

sprayer

, see page 8. If it doesn’t start, see

manual 307–158.

Increase pressure. See page 9.

Clean the filter

.

Remove tip and/or filter and clean.

Shut of

f sprayer

and add fluid immediately*. See

page 5.

Return sprayer for repair

.

Return sprayer for repair

.

Service pump. See manual .

Displacement pump operates, but

output is low on upstroke.

Piston ball check not seating properly

.

Piston packings worn or damaged.

Service piston ball check. See manual 307–862

.

Replace packings. See manual

Displacement pump operates but

output is low on downstroke and/

or on both strokes.

Piston packings worn or damaged.

Intake valve ball check not seating

properly.

Replace packings. See manual 307–862

Service intake valve ball check. See manual

307–862.

Paint leaks into wetcup

Loose wet–cup

Throat packings worn or damaged.

T

ighten just enough to stop leakage.

Replace packings. See manual 307–862

Excessive leakage around

hydraulic motor piston rod wiper

.

Piston rod seal worn or damaged.

Replace these parts. See manual 307–158.

Fluid delivery is low

.

Pressure setting too low

.

Displacement pump outlet filter (if

used) is dirty or clogged.

Hydraulic pump is worn or damaged.

Hydraulic motor is worn or damaged.

Large pressure drop in fluid hose.

Increase pressure. See page 9.

Clean filter

Return sprayer for repair

.

Return sprayer for repair

.

Use larger diameter hose.

The sprayer overheats.

Cooler or blower is worn or damaged.

Replace. See page 13.

Spitting from gun.

Air in fluid pump or hose.

Fluid supply is low or empty

.

Check for loose connections on siphon

assembly

, tighten, then reprime pump.

Refill supply container

.

*Check

hydraulic fluid level often. Do not allow it to become too low

. Use only Graco approved hydraulic fluid. See pages

5 and 20.

Loading...

Loading...